Carbon based sliding plate material of high speed railway pantograph and preparation method thereof

A high-speed railway, pantograph technology, applied in the direction of collectors, electric vehicles, power collectors, etc., to achieve the effects of small wear, short production cycle, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

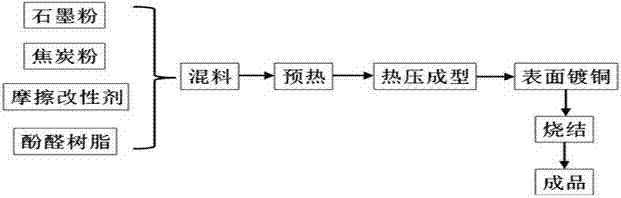

Method used

Image

Examples

Embodiment 1

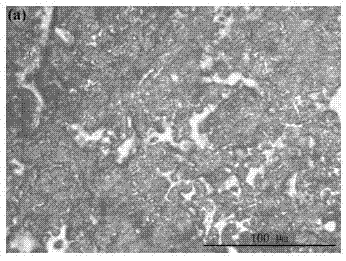

[0034]The carbon-based composite materials for pantograph slides are: 15 wt% of 130-mesh graphite, 55 wt% of 120-mesh coke powder, 20 wt% of thermosetting phenolic resin, 8 wt% of 150-mesh alumina, 2 wt% of 160-mesh glass powder. The method of dry mixing, after ball milling for 15 h, preheated to 80 °C, held for 3 h; under the pressure of 200 MPa, hot pressing at 180 °C for 4 h; in nitrogen atmosphere, the voltage was 70 V, using surface strengthening The processor plated copper on the surface of the carbon substrate for 5 h; in an argon atmosphere, sintered at 800 °C for 2 h to prepare a carbon-based friction material sample 1 with a surface modification layer. Its metallographic photos are as figure 2 As shown, the friction performance curve is as Figure 4 As shown, the basic properties of the surface modification layer are shown in Table 1 below.

[0035] Table 1

[0036] Sample 1 Sample 2 Vickers hardness HV 94.5 92.3 ResistivityμΩ·m 17.78 ...

Embodiment 2

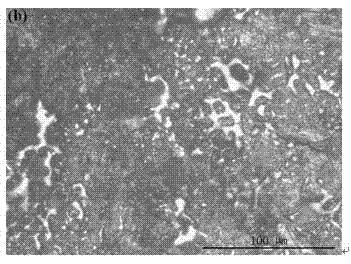

[0039] The carbon-based composite materials for the pantograph slide plate are: 25 wt% of 180-mesh graphite, 40 wt% of 160-mesh coke powder, 25 wt% of thermosetting phenolic resin, 6 wt% of 180-mesh alumina, 4 wt% of 190-mesh glass powder. The method of state mixing, ball milling for 10 h, preheating to 60 ℃, holding for 4 h; under the pressure of 250 MPa, hot pressing at 200 ℃ for 8 h; Copper was plated on the surface of the carbon substrate for 4 h; in an argon atmosphere, it was sintered at 1000 °C for 5 h to prepare a carbon-based friction material sample 2 with a surface modification layer. Its metallographic photos are as image 3 As shown, the friction performance curve is as Figure 5 As shown, the basic properties of the surface modification layer are shown in Table 2 below.

[0040] Table 2

[0041] Sample 1 Sample 2 Vickers hardness HV 94.5 92.3 ResistivityμΩ·m 17.78 14.26 coefficient of friction 0.25 0.24

[0042] The fri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com