Fork truck stack board and its manufacturing method

A technology of pallets and forklifts, applied in the field of forklift pallets and its production, can solve the problems of insufficient waterproof and corrosion resistance, and achieve the effect of increased strength and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

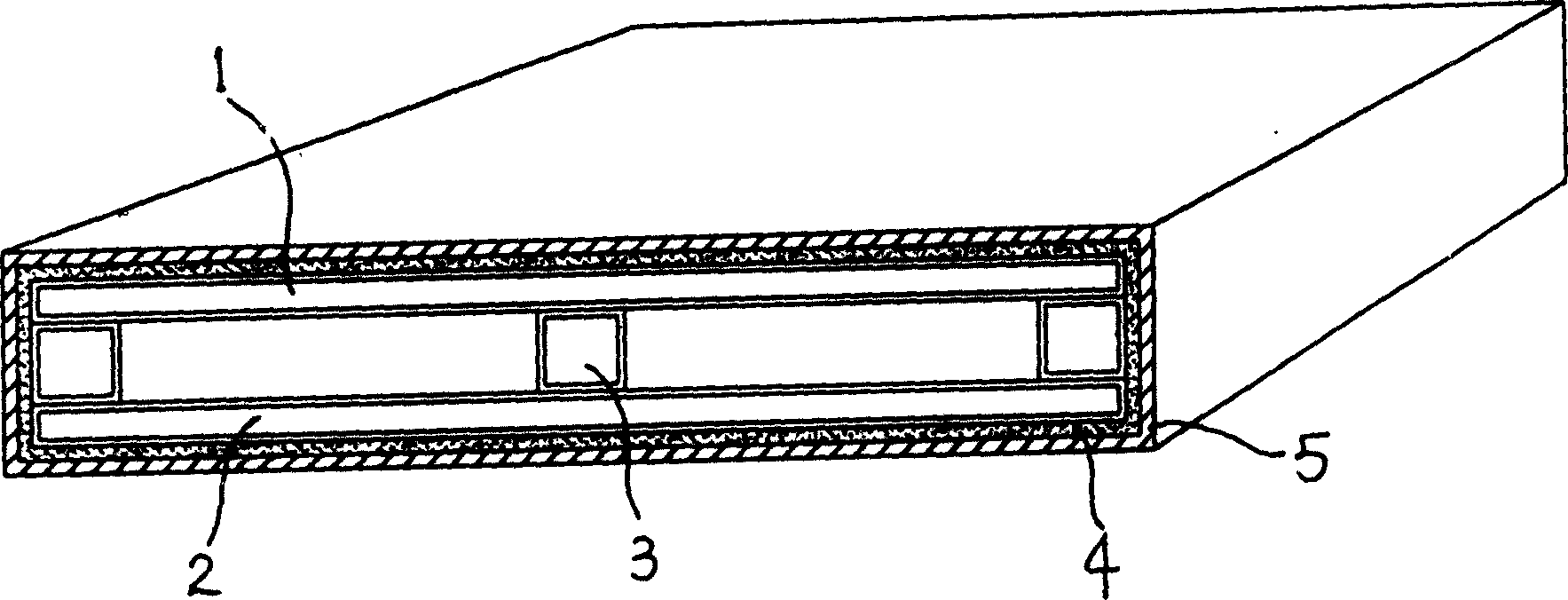

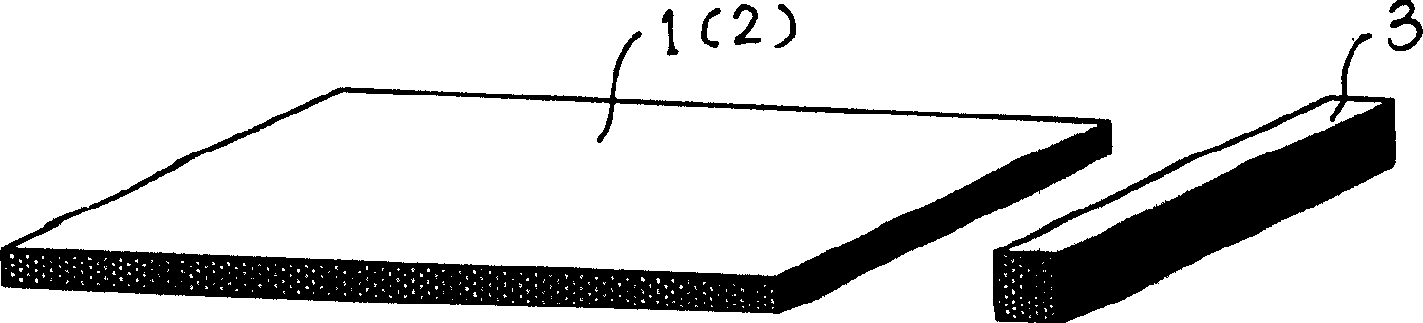

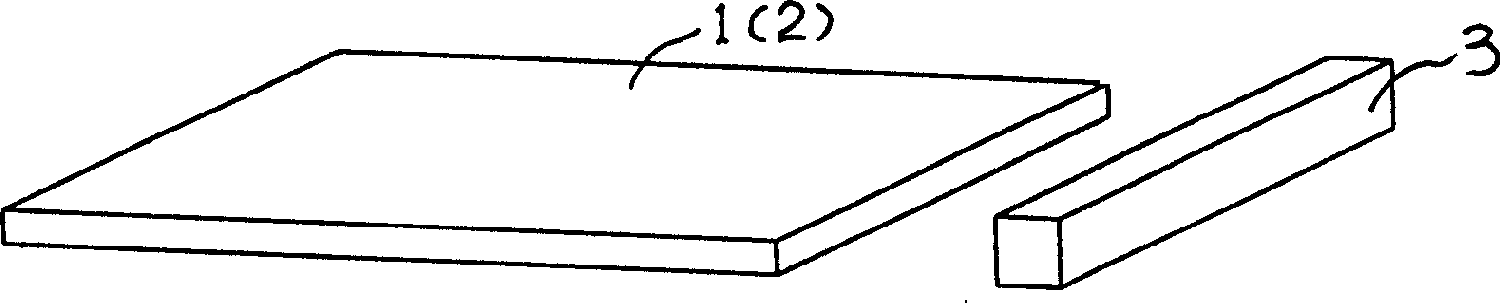

[0010] The invention relates to a forklift pallet and a manufacturing method thereof. Attached below figure 1 , 2 , the present invention is described in detail with a specific embodiment:

[0011] See attached figure 1 , 2 , the forklift pallet of the present invention is composed of upper and lower panels 1, 2 and several load-bearing plates 3 between the upper and lower panels 1, 2, and the upper and lower panels 1, 2 are fixed to each other by the load-bearing plates 3. The hole is for the steel plug of the forklift to be inserted. Wherein said upper and lower panels 1, 2 and bearing plate 3 adopt honeycomb paperboard, this is because according to the principle of honeycomb structure, honeycomb paperboard has better strength, and this is why the present invention adopts it as the reason place of raw material. Glass fibers 4 are pasted on the surfaces of the upper and lower panels 1 , 2 and the bearing plate 3 , and a layer of chemical resin 5 is applied on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com