Biologically degradable pre-coating film

A biodegradable, pre-coating film technology, applied in the direction of film/sheet-like adhesives, adhesives, etc., can solve the problem of non-degradable films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Glossy pre-coated film

[0022] Substrate 1 is prepared in advance. Substrate 1 is a glossy cellulose acetate film (clarifol, UK) with a thickness of 17 microns.

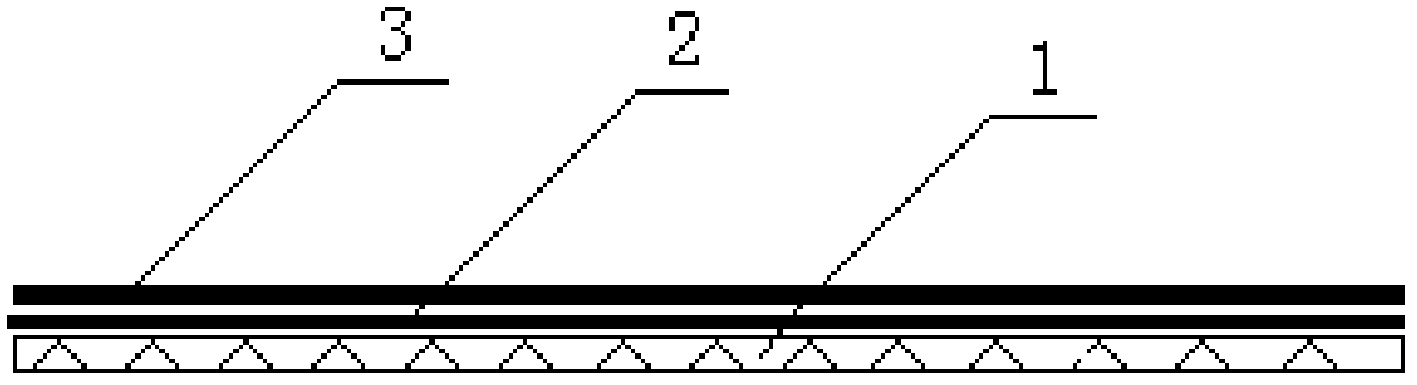

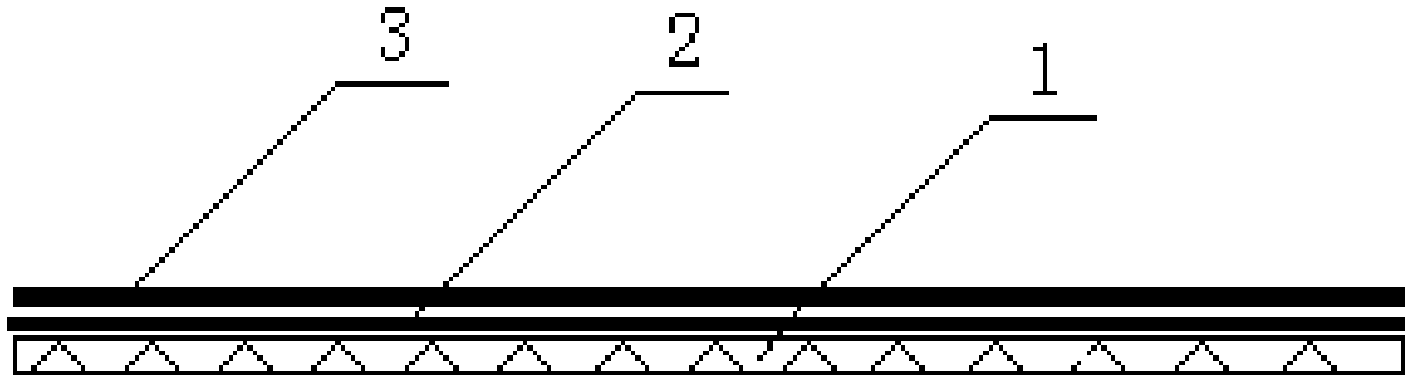

[0023] see figure 1 . The biodegradable precoat film has a width of 1235mm. The base material (1), the middle layer (2) and the hot melt adhesive layer (3) have the same width. The biodegradable precoat film has three layers, the first layer is a base material (1), the second layer is an intermediate layer (2), and the third layer is a hot melt adhesive layer (3). The substrate (1) is a cellulose acetate film with a width of 1255 mm. The middle layer (2) is polyethyleneimine (PEI, Dainippon Ink Company, EP-108), and the hot-melt adhesive layer (3) is ethylene-vinyl acetate (EVA) hot-melt adhesive (Thailand TPI Company, SV1040). Using a composite production line composed of an extruder and a hot-melt adhesive composite machine (Guangdong Huilong Plastic Machinery, EXC1700 / 90S-F-2), the interme...

Embodiment 2

[0025] Example 2: Matt precoat film

[0026] Substrate 1 is prepared in advance. Substrate 1 is a cellulose acetate matte film (clarifol, UK) with a thickness of 21 microns.

[0027] The biodegradable precoat film has a width of 1235mm. The base material (1), the middle layer (2) and the hot melt adhesive layer (3) have the same width. The biodegradable precoat film has three layers, the first layer is a base material (1), the second layer is an intermediate layer (2), and the third layer is a hot melt adhesive layer (3). The substrate (1) is a cellulose acetate film with a width of 1255 mm. The middle layer (2) is polyethyleneimine (PEI, Dainippon Ink Company, EP-108), and the hot-melt adhesive layer (3) is ethylene-vinyl acetate (EVA) hot-melt adhesive (Thailand TPI Company, SV1040). The middle layer (2) is evenly coated on the surface of the substrate (1), and the coating amount is 0.011g / m 2 , on the surface of the middle layer (2) uniformly compound a layer of hot me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com