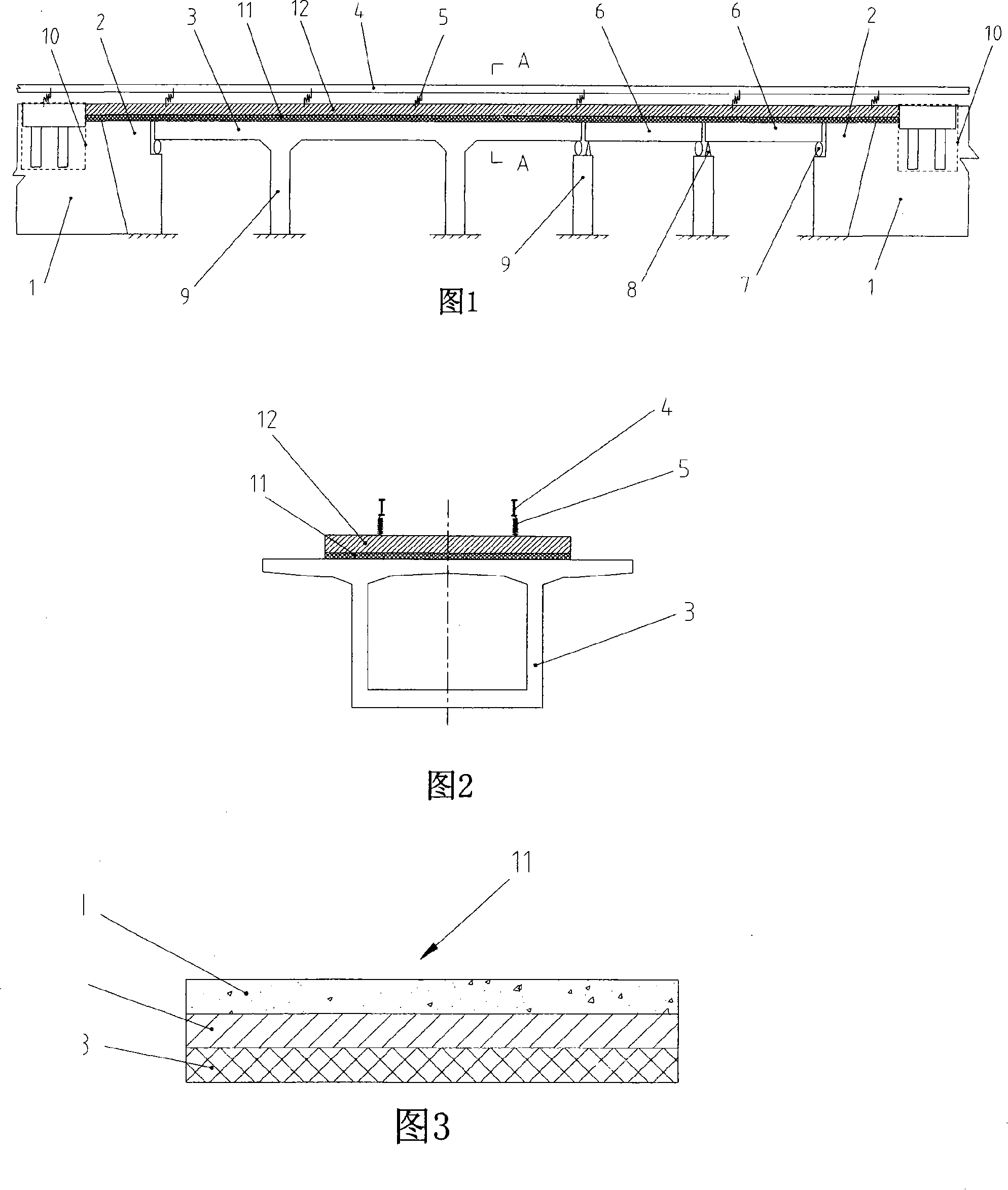

Sliding layer for bridge trackway longitudinal spacer assembly

A technology of longitudinal isolation and sliding layers, which is applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of increasing bridge piers, increasing track costs, increasing masonry volumes of bridge piers and abutments, etc., and achieves low friction consumption and high friction coefficient small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

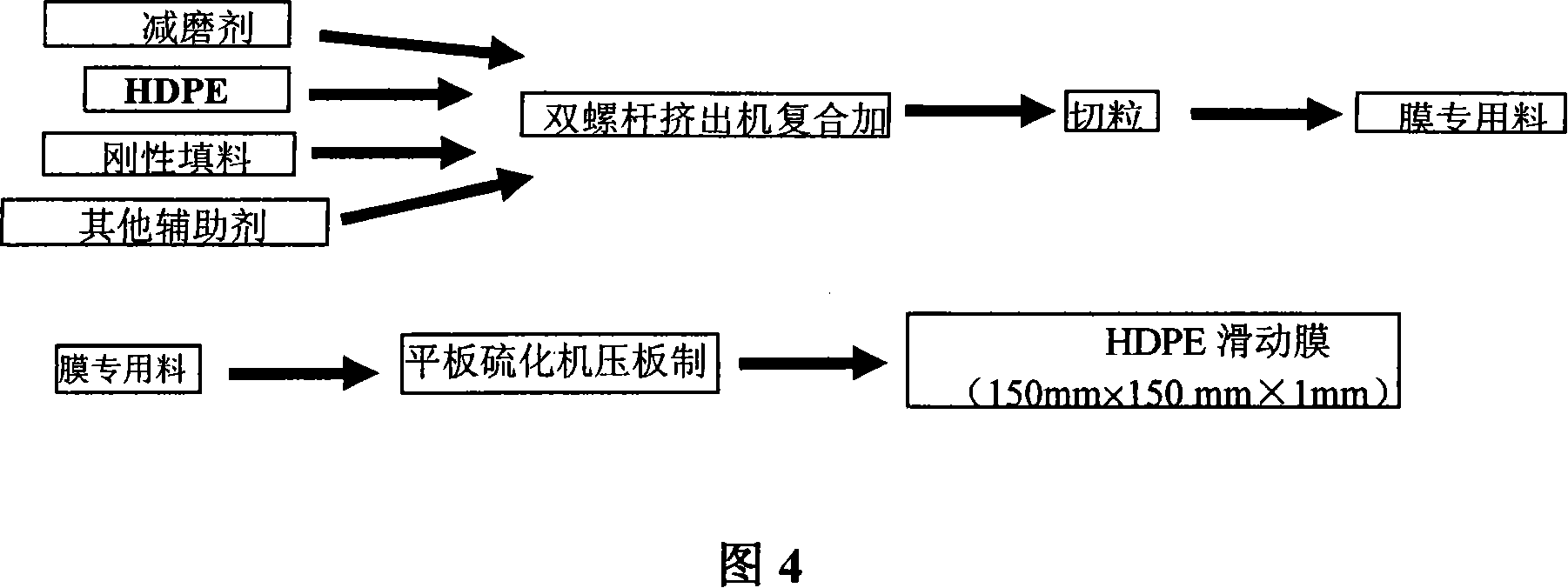

[0051] Embodiment 1: Embodiment 1 is a three-layer structure. The cloth film layer of the upper layer is a composite film of PU film and PA cloth arranged in sequence from top to bottom, and the sliding film of the middle layer is an HDPE sliding film. The cloth film layer of the lower layer is a composite film of PU film and PA cloth arranged in sequence from top to bottom.

[0052] The advantage of embodiment 1 is that (1) the coefficient of friction of PA and HDPE on the grinding surface is only 0.066 (theoretical value), which can better meet the requirements of the sliding layer material on the friction performance of the cloth-film on the grinding surface; (2) as a It is an elastomer material with excellent performance. The PU film has good shear resistance, compression resistance, fatigue resistance, creep resistance and elastic recovery performance. Free expansion and contraction without material damage due to shear and creep;

[0053] (3) PU membrane has strong bondi...

Embodiment 2

[0056] Embodiment 2 is a two-layer structure, the cloth film layer of the upper layer is a composite film of polyester filament geotextile and HDPE sliding film arranged in sequence from top to bottom, and the cloth film layer of the lower layer is formed from the upper layer A composite film of PA cloth and PU film arranged in sequence.

[0057] The advantage of embodiment 2 is: it has some advantages of embodiment 1, and the price is much lower than the former, and because the sliding film is bonded to the polyester filament geotextile, the cement can be poured directly on the polyester filament geotextile, and the sliding film It can be limited without sliding out. The industrial preparation technology of HDPE and polyester filament geotextiles is mature, and the construction is relatively convenient.

[0058] The disadvantage of embodiment 2 is that it is similar to embodiment 1. In addition, due to the lack of the free sliding layer of the embodiment 1 scheme, the wear o...

Embodiment 3

[0060] Embodiment 3 is a three-layer structure, and the cloth film layer of the upper layer is a polyester filament composite polyethylene geomembrane, referred to as a composite geomembrane, which includes polyester filament geomembranes that are bonded together and arranged sequentially from top to bottom. Cloth, PE waterproof layer, and polyester filament geotextile; the sliding film of the middle layer is HDPE sliding film; the cloth of the lower layer is polyester filament geotextile. The thickness of the polyester filament geotextile is 2-2.5mm, the thickness of the HDPE sliding film is 1-1.5mm, and the thickness of the PE waterproof layer is 0.3-0.6mm. The performance indicators of polyester filament composite polyethylene geomembrane are shown in Table 3.

[0061] The advantages of Embodiment 3 are: (1) The friction coefficient between polyester filament geotextile and HDPE is only 0.10 (theoretical value), although it is higher than polyethylene film and PA cloth fric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com