Modified nano material lubricating oil

A nanomaterial and lubricating oil technology, applied in the field of lubricating oil, can solve the problem that graphite is difficult to exert its lubricating performance, and achieve the effect of improving power, reducing equipment failure rate and prolonging mechanical service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described below in conjunction with examples, so as to better understand the present invention.

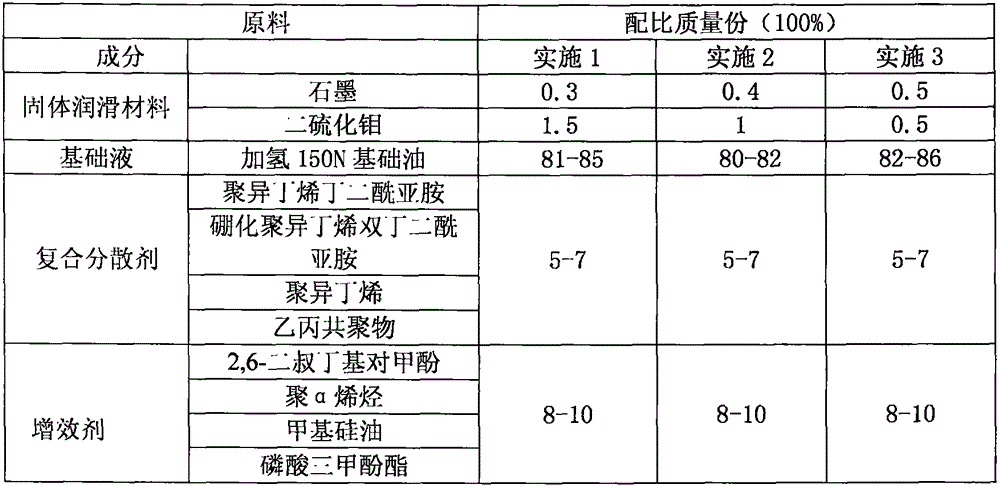

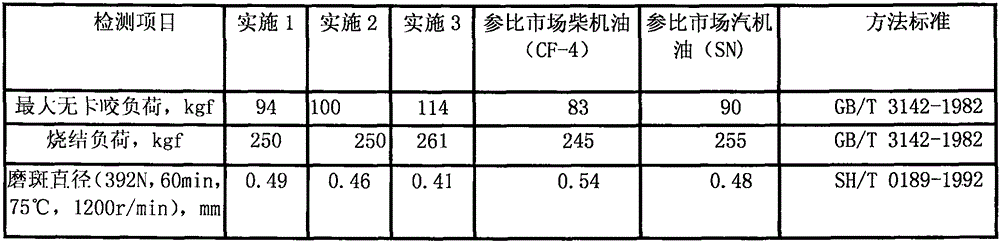

[0016] In the following examples, different proportions are adopted for batching, and the proportions are shown in Table 1.

[0017] Table 1: Proportion of different materials

[0018]

[0019] The concrete preparation process of above-mentioned lubricating oil is:

[0020] (1) Wetting process of solid lubricating materials: pump hydrogenated base oil, graphite, molybdenum disulfide and synergist with half of the above mass percentage into the stirring tank, the stirring speed is 800-1000r / min, and the stirring time is 1.5~2h;

[0021] (2) Dispersant pretreatment process: put the other half of the above mass percentage of base oil and composite dispersant into an ultrasonic oscillator for heating and dilution, and the temperature is stably controlled at 60 degrees;

[0022] (3) Stable dispersion to solve the agglom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com