Trackless counter weight assembly and trackless lift car

A car and counterweight frame technology, applied in the field of vertical elevators, can solve problems such as difficulty in correction of track distortion, bumps and noise at joints, difficulty in transportation and installation, and achieves small length and size, convenient on-site construction, and good orientation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

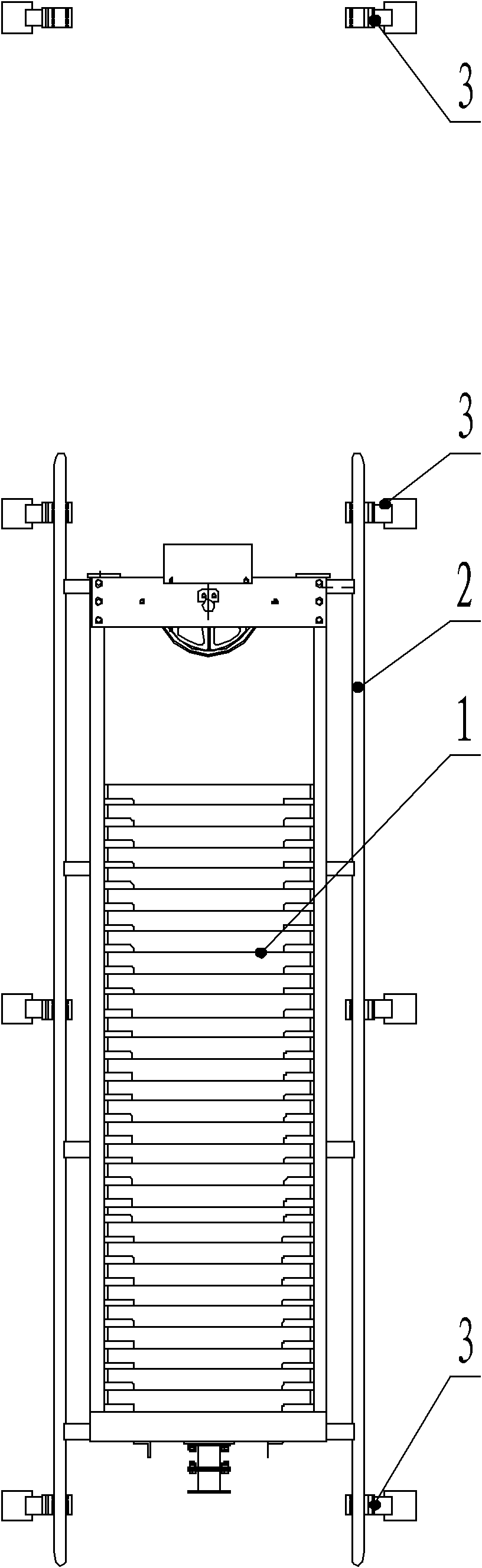

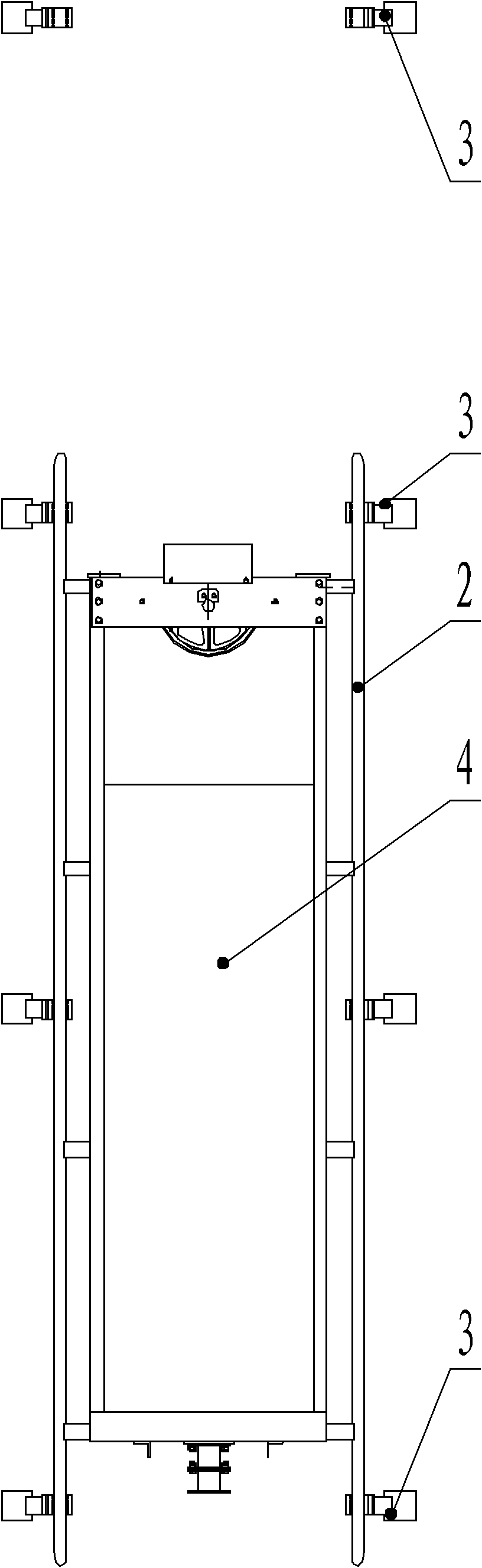

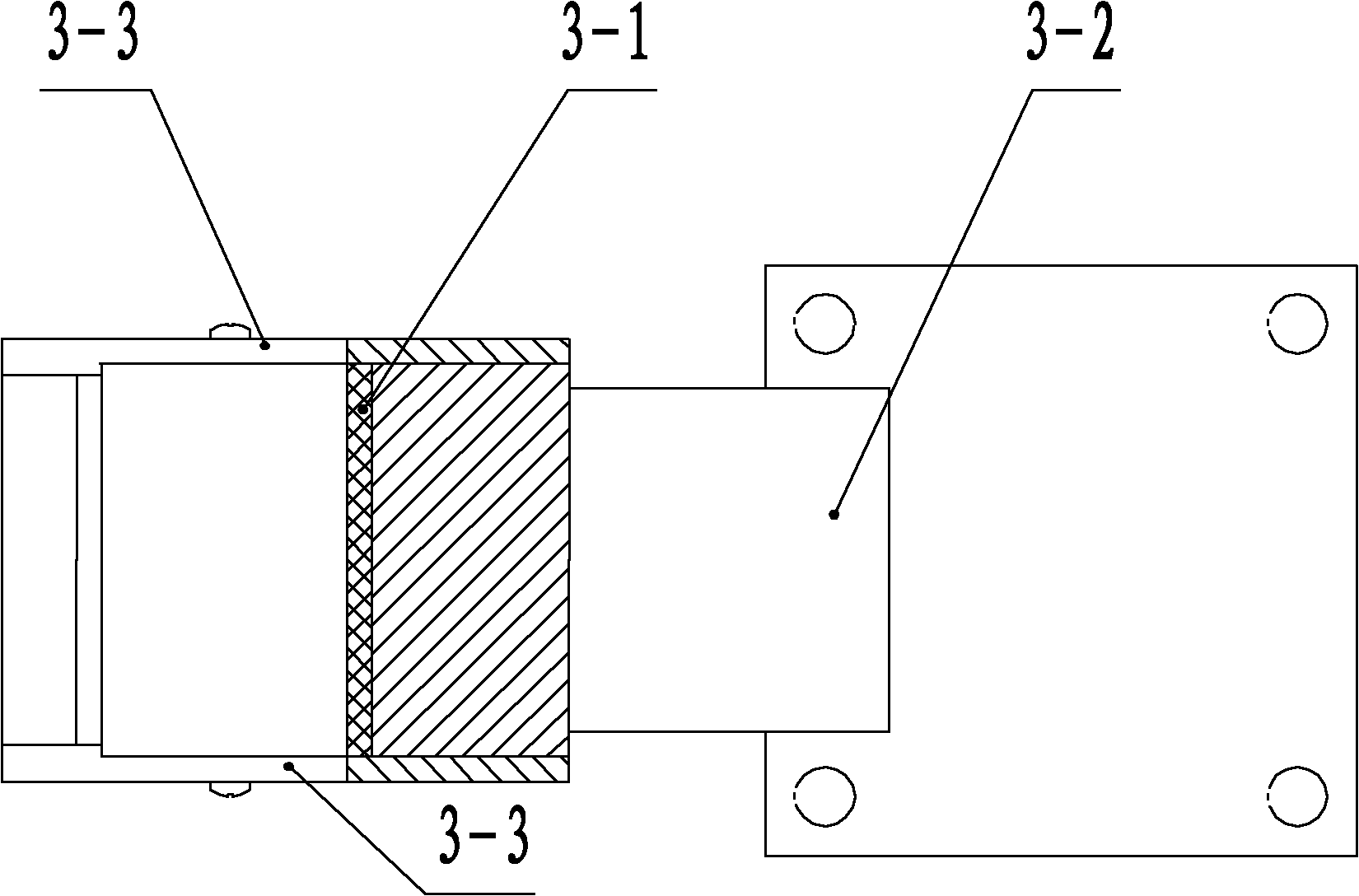

[0028] Such as figure 1 As shown, a trackless counterweight device includes a counterweight frame assembly 1, and two guide rods 2 are respectively installed and fixed on both sides of the counterweight frame assembly 1. The cross section of the guide rod 2 is circular, and the end is half Conical shape, guide rod adopts steel-plastic composite material, install and fix some guide sleeve assemblies 3 that slide with guide rod 2 on the shaft wall of the elevator, the length of guide rod is more than twice the distance between the upper and lower guide sleeve assemblies. Such as image 3 with Figure 4 As shown, the guide sleeve assembly includes a guide sleeve 3-1 and a guide sleeve seat 3-2 for fixing the guide sleeve. The guide sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com