Preparation method of pantograph slide plate for high-speed train

A pantograph sliding plate, high-speed train technology, applied in applications, current collectors, ceramic products, etc., can solve problems such as high cost, achieve the effects of simple and easy-to-control preparation process, improve compactness, and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

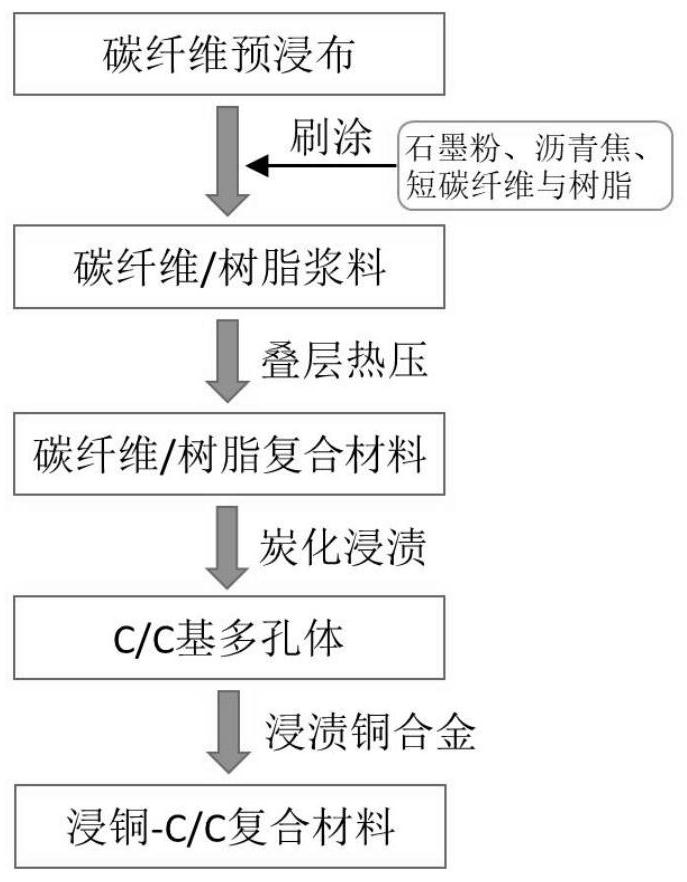

Method used

Image

Examples

Embodiment 1

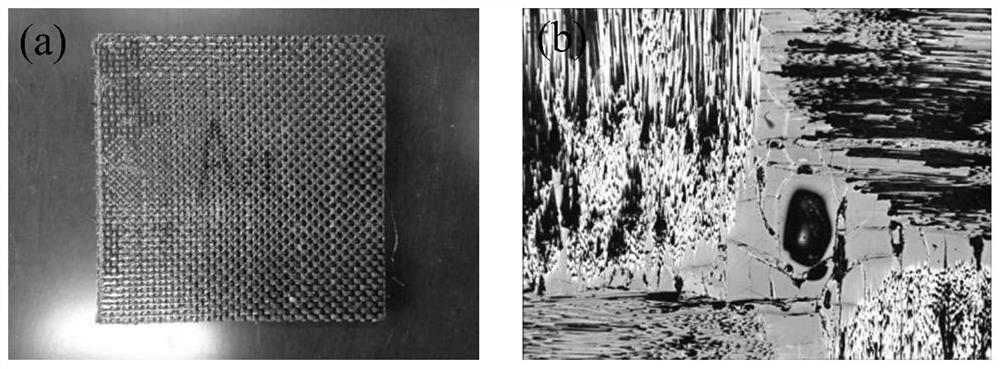

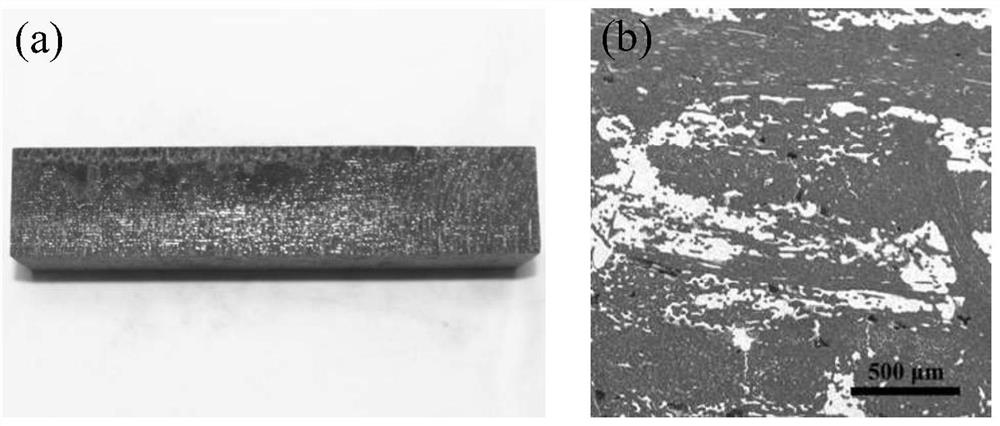

[0045] The cross carbon fiber pre-impregnated carbon cloth with a phenolic resin content of 40vol% is used. The coating is a mixed slurry of pitch-based short carbon fiber, graphite powder, pitch coke powder and phenolic resin, wherein the resin content is 60wt%, pitch-based short carbon fiber is 15wt%, graphite powder is 20wt%, and the mass ratio of pitch coke is 5wt%. Stir mechanically until evenly dispersed; the pitch-based short carbon fiber has a length of 500 μm, the graphite powder is flake graphite powder with a size of 100 mesh, and the pitch coke powder has a size of 500 mesh. Brush the mixed slurry evenly on the surface of the prepreg cloth twice by brushing method, and raise the temperature to 80°C until the ethanol is completely volatilized.

[0046] After brushing the pitch-based carbon fibers, lay them up alternately; then place them on a flat vulcanizer for curing and molding under a pressure of 40MPa, press at a temperature of 180°C, and hold the pressure for ...

Embodiment 2

[0050] The cross carbon fiber pre-impregnated carbon cloth with phenolic resin content of 30vol% is used. The coating is a mixed slurry of pitch-based short carbon fiber, graphite powder, pitch coke powder and phenolic resin, wherein the resin content is 55wt%, pitch-based short carbon fiber is 15wt%, graphite powder is 25wt%, and the mass ratio of pitch coke is 5wt%. Stir mechanically until evenly dispersed; the pitch-based short carbon fiber has a length of 500 μm, the graphite powder is flake graphite powder with a size of 100 mesh, and the pitch coke powder has a size of 500 mesh. Brush the mixed slurry evenly on the surface of the prepreg cloth twice by brushing method, and raise the temperature to 80°C until the ethanol is completely volatilized.

[0051] After brushing the pitch-based carbon fibers, lay them up alternately; then place them on a flat vulcanizer for curing and molding under a pressure of 40MPa, press at a temperature of 180°C, and hold the pressure for 3 ...

Embodiment 3

[0055] A unidirectional carbon fiber prepreg carbon cloth with a phenolic resin content of 45vol% is used. The coating is a mixed slurry of pitch-based short carbon fiber, graphite powder, pitch coke powder and phenolic resin, wherein the resin content is 70wt%, pitch-based short carbon fiber is 10wt%, graphite powder is 15wt%, and the mass ratio of pitch coke is 5wt%) , mechanically stirred until evenly dispersed; wherein the length of the pitch-based short carbon fiber is 800 μm, the graphite powder is flake graphite powder with a size of 100 mesh, and the pitch coke powder size is 500 mesh. Brush the mixed slurry evenly on the surface of the prepreg cloth twice by brushing method, and raise the temperature to 80°C until the ethanol is completely volatilized.

[0056] Use unidirectional carbon fiber pre-impregnated carbon cloth with a pure phenolic resin content of 100%. After brushing the pitch-based carbon fiber, lay it vertically and alternately; Put it into a carbonizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com