Ironing picture wooden floor and its manufacturing technique

A technology of solid wood flooring and production technology, applied in the technology for producing decorative surface effects, wood processing equipment, decorative art, etc., can solve problems such as monotonous color, affect the quality of the floor, and easy damage to the surface film, and achieve bright patterns and colors , Good for cleaning and anti-friction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

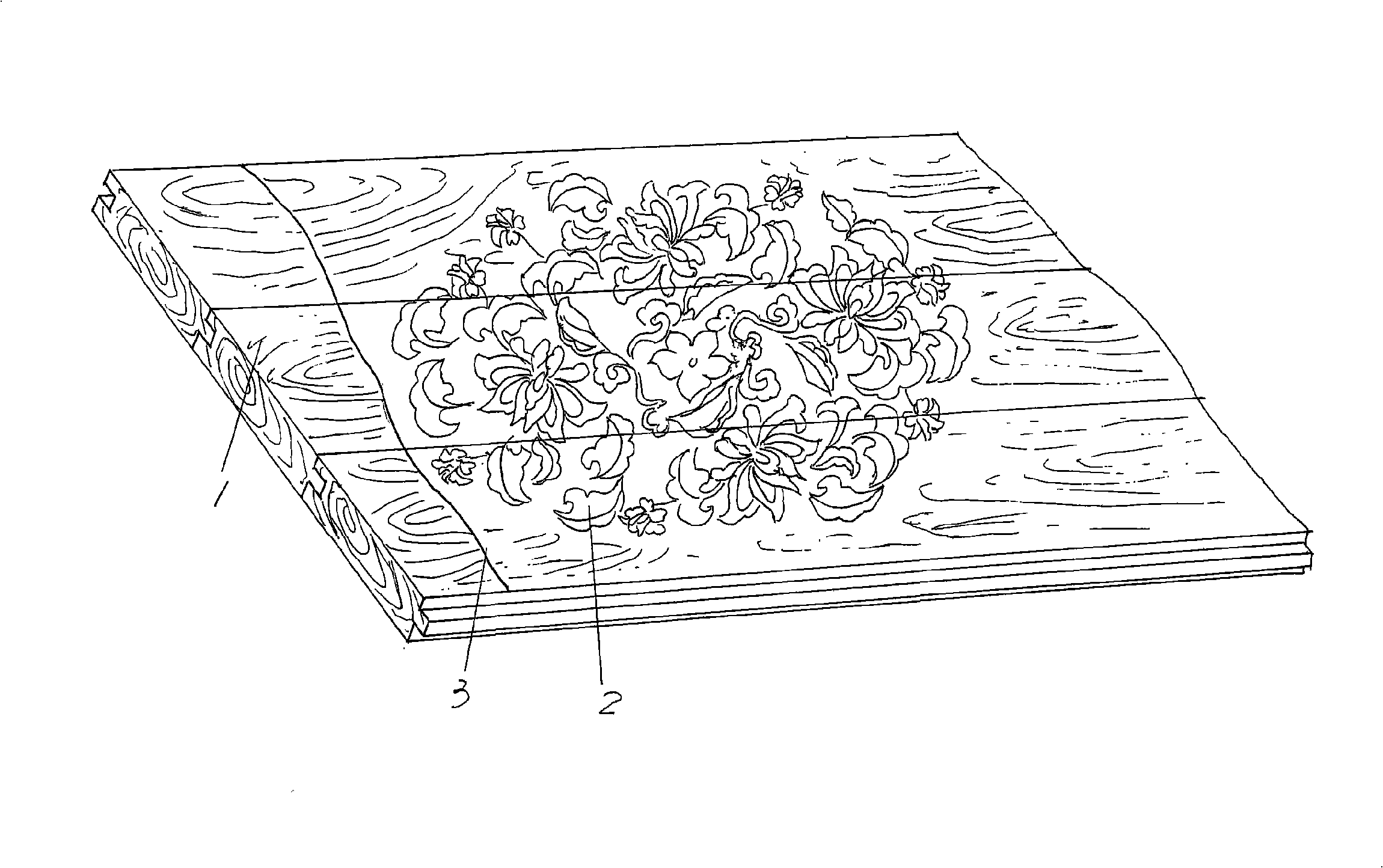

[0021] a) Select the wood, and cut it into a solid wood substrate 1 of the required length and width according to the size provided by the user. The material type of the solid wood substrate 1 is not subject to any restrictions, and it can be birch, ash, oak, teak, rosewood wood, oak, etc.;

[0022] b) drying and finishing the cut solid wood substrate 1, wherein the surface finishing treatment of the solid wood substrate 1 can be sanding or polishing with corresponding equipment, and removing the dust remaining on the surface of the solid wood substrate 1;

[0023] c) Using a heat press machine to transfer the pattern on the heat transfer paper to the required heat transfer position on the solid wood substrate 1 after heating and pressing, so that the surface of the solid wood substrate 1 is formed with a heat transfer paper pattern layer 2, wherein : The thickness of the pattern layer 2 of the heat transfer paper is controlled within 0.55mm, the temperature required for heat ...

Embodiment 2

[0026] Only change the temperature required for the transfer of the heat press machine in step c) to 150°C and the pressure to 1.5kg / cm 2 , change the time to 10 seconds; and change the hydraulic press in step d) to a 1200-ton hydraulic press, change the temperature of pressing to 200°C, and change the pressure to 20kg / cm 2 , the time is changed into 1 minute, and all the other are with embodiment 1.

Embodiment 3

[0028] Only change the temperature required for the transfer of the heat press machine in step c) to 200°C and the pressure to 2kg / cm 2 , change the time to 5 seconds; and change the oil press in step d) to a 1400-ton oil press, change the temperature of the pressing to 250°C, and change the pressure to 30kg / cm 2 , the time was changed into 30 minutes, and all the other were with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com