Multi-layer thermal transfer ribbon and manufacturing method thereof

A technology of thermal transfer printing and carbon ribbon, which is applied in printing, ink ribbon, ink, etc., can solve the problems of graphic damage, ink layer not resistant to scratching, low content of straight chain hydrocarbons, etc., to achieve improved scratch resistance and good peeling performance , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

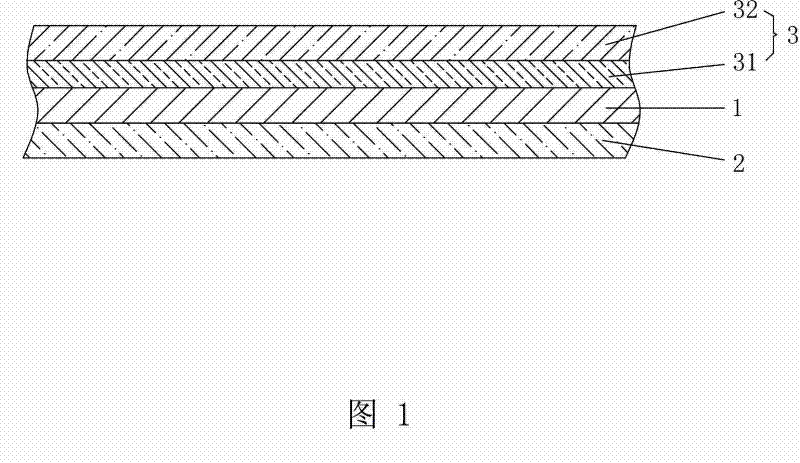

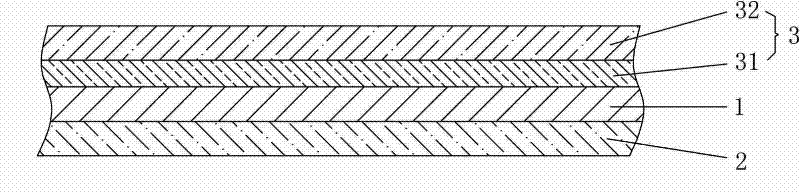

[0031] refer to figure 1 , a multilayer thermal transfer carbon ribbon, the multilayer thermal transfer ribbon includes a base belt 1 made of a biaxially oriented polyester film without corona treatment with a thickness of 4.5-5.0 microns, a heat-resistant ink layer 2 is coated on one side of the base tape 1, and the thermal transfer ink layer 3 is coated on the other side of the base tape 1. In order to keep the long-term clarity of the image printed on the medium, it is necessary to require the ink layer to be easily peeled off from the base tape 1 and have a sufficiently high bonding strength with the print medium. For this reason, the thermal transfer ink layer 3 is peeled off. The ink layer 31 and the bonding ink layer 32 are composed, the peeling ink layer 31 is directly coated on the surface of the base tape 1, the bonding ink layer 32 is coated o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com