Preparation method of graphene/carbon nano tube-reinforced and toughened carbon fiber composite material

A carbon nanotube, strengthening and toughening technology, applied in the field of graphene composite materials, can solve problems such as poor toughness, and achieve the effects of fewer steps, simple process, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

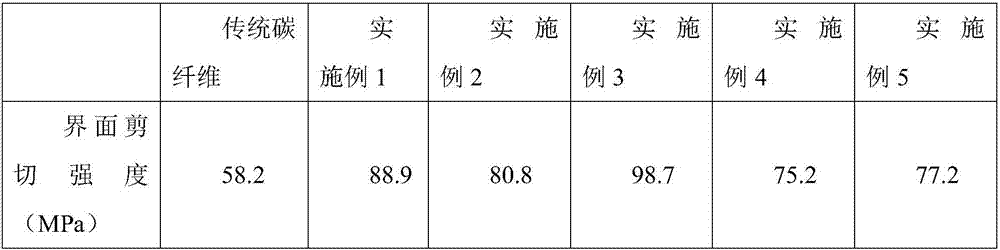

Examples

Embodiment 1

[0051] (1) Preparation of three-dimensional graphene flocs

[0052] Add 40mL H to a 500mL beaker 2 SO 4 (mass fraction 98%) and 6g (NH 4 ) 2 S 2 o 8 , stirred to (NH 4 ) 2 S 2 o 8 Dissolve, add 1.5g of graphite powder (32 mesh), mechanically stir for 30min, slowly add 5mL of 30wt% H 2 o 2 After standing at room temperature for 8 hours, the expanded graphene aggregates were obtained, washed with water until neutral, and dried in a dryer at 60°C for 12 hours to obtain three-dimensional graphene flocs.

[0053] (2) Preparation of surface modification of carbon nanotubes

[0054] Add 40mL H to a 500mL beaker 2 SO 4 (98%) and 6g (NH 4 ) 2 S 2 o 8 , stirred to (NH 4 ) 2 S 2 o 8 Dissolve, add 3g multi-walled carbon nanotubes (diameter 60nm), mechanically stir for 30min, slowly drop 5mL H 2 o 2 , after standing at room temperature for 8 hours, acid-modified carbon nanotubes were obtained, washed with water until neutral, and dried in a dryer at 60° C. for 12 hou...

Embodiment 2

[0060] (1) with embodiment 1;

[0061] (2) with embodiment 1;

[0062] (3) Preparation of graphene / modified carbon nanotube sizing agent

[0063] Take 1.5g of sodium lauryl sulfate, add it to 92.5g of epoxy resin solution, and wait for the sodium lauryl sulfate to dissolve. Add the three-dimensional graphene flocs prepared in Step 1 (1) and the surface-modified carbon nanotubes prepared in Step 5 (2) in sequence, and stir at 1000 rpm for 30 min. Placed in an ultrasonic crusher, ultrasonic power 800W, continuous ultrasonic 60min.

[0064] (4) with embodiment 1.

Embodiment 3

[0066] (1) with embodiment 1;

[0067] (2) with embodiment 1;

[0068] (3) Preparation of graphene / modified carbon nanotube sizing agent

[0069] Get 1.5g polyvinylpyrrolidone, add in the epoxy resin solution of 92.5g, after the polyvinylpyrrolidone dissolves. Add 3 g of the three-dimensional graphene floc prepared in step (1) and 3 g of the surface-modified carbon nanotubes prepared in step (2) in sequence, and stir at 1000 rpm for 30 min. Placed in an ultrasonic crusher, ultrasonic power 1200W, continuous ultrasonic 120min.

[0070] (4) with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com