Prestressed Reinforcement Grounding Device for Concrete Members

A technology of prestressed steel bar and grounding device, which is applied in the direction of connecting contact materials, roads, buildings, etc., can solve the problem that the prestressed steel bar cannot be grounded, and achieve the effect of eliminating stray current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

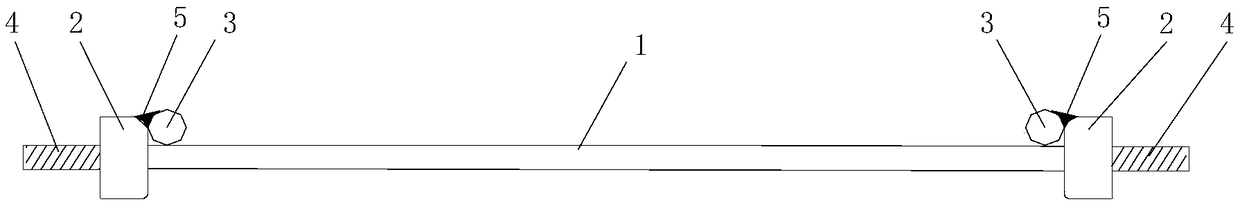

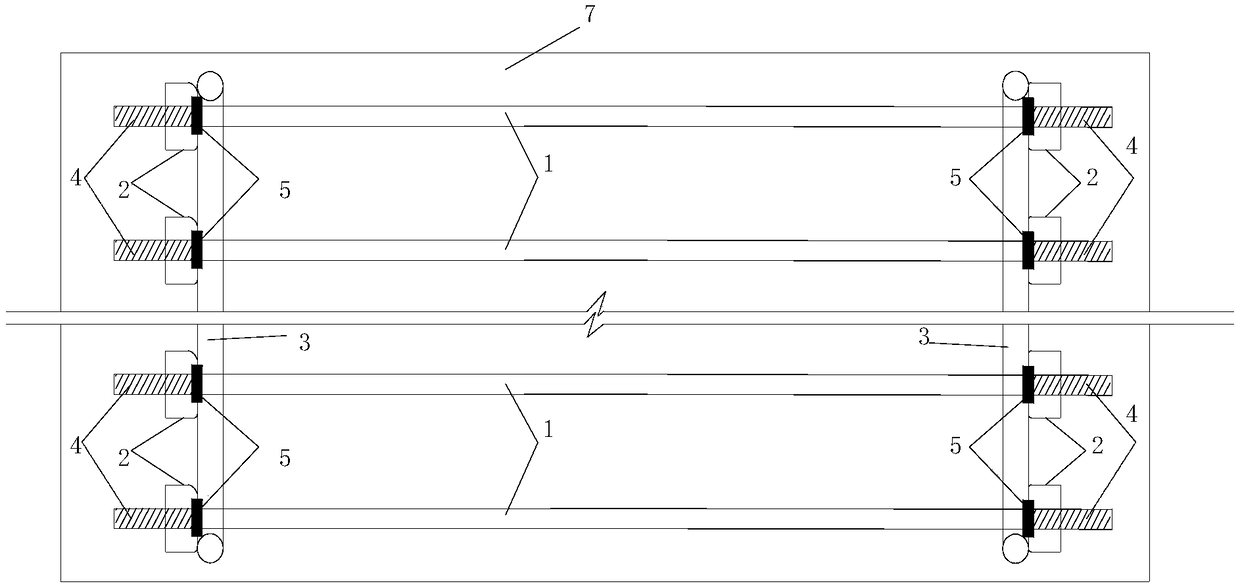

[0035] like figure 2 As shown, for the pre-tensioned prestressed steel bar 1 that is usually not provided with anchors, a section of thread 4 is provided at both ends of the prestressed steel bar 1, and a metal anchor 2 is placed on the thread 4, and the metal anchor 2 is connected to the prestressed steel bar 1 and After the grounding steel bar 3 and the tensioning of the prestressed steel bar are completed, the prestressed concrete member 7 is poured.

[0036] A non-prestressed grounding steel bar 3 is arranged perpendicular to each prestressed steel bar 1 at its end, close to the metal anchor 2, and welded together with the metal anchor 2 through the welding point 5 (or through Fixture connection), thereby solving the problem that the steel bar cannot be welded in the tension zone of the prestressed steel bar 1.

[0037] Add graphite powder and other materials within the close contact range between the anchor and the thread to improve the electrical conductivity between th...

Embodiment 2

[0040] like figure 2 As shown, for the prestressed steel bar 1 with anchors 2 at both ends, it is made by post-tensioning method, and the prestressed concrete member 7 is poured first and the pipe hole is reserved. After the prestressed steel bar 1 is installed, the grounding steel bar 3 passes through the welding point 5 is welded to the metal anchor 2, so that it is indirectly connected to the prestressed steel bar 1, the specific connection is the same as in embodiment 1, and then filled with grout.

[0041] Add graphite powder and other materials within the close contact range between the anchor and the thread to improve the electrical conductivity between the anchor and the thread.

[0042] In this embodiment, the strength of the anchor piece needs to be increased during the post-tensioning process, so as to ensure that the strength of the grounding steel bar 3 can still meet the tension requirement of the steel bar when it is welded on it.

Embodiment 3

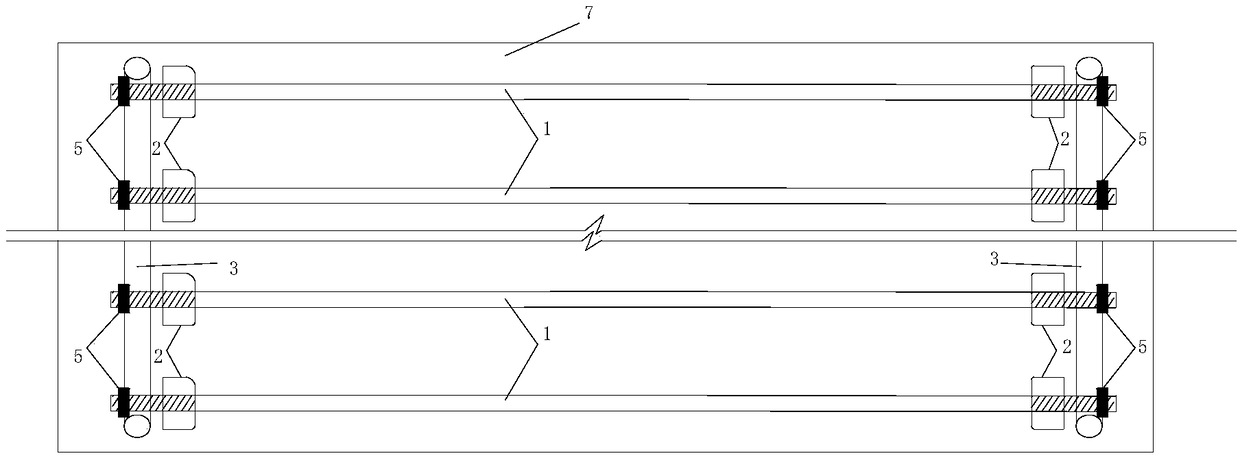

[0044] like image 3 As shown, the prestressed steel bar 1 is produced by pre-tensioning or post-tensioning, and the end of the prestressed steel bar 1 is provided with a thread 4 outside the tensile zone.

[0045] In the pre-tensioning method, the prestressed steel bar 1 is stretched first, and the anchor piece 2 is sleeved on the thread 4, but the grounding steel bar 3 is directly welded on the thread 4, and finally the prestressed concrete member 7 is poured.

[0046] In the post-tensioning method, the concrete is poured first, and then the prestressed steel bar 1 is stretched. The anchor piece 2 is socketed on the thread 4, but the grounding steel bar 3 is directly welded on the thread 4, and finally the grouting is filled.

[0047] Specifically, a non-prestressed grounding steel bar 3 is horizontally arranged at the end of each prestressed steel bar 1 perpendicular to the prestressed steel bar, and is welded together at the intersection of the anchor 2 outside, which also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com