A continuous casting tundish argon-blowing upper nozzle seat brick and its installation method and application

A technology of continuous casting tundish and nozzle block, which is applied in casting equipment, casting molten material container, metal processing equipment, etc., and can solve the problems of large tundish injection margin, high construction cost, increased consumption of steel materials, cost, etc. , to achieve the effect of suppressing the problem of eddy current slag entrainment, promoting flotation and removal, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

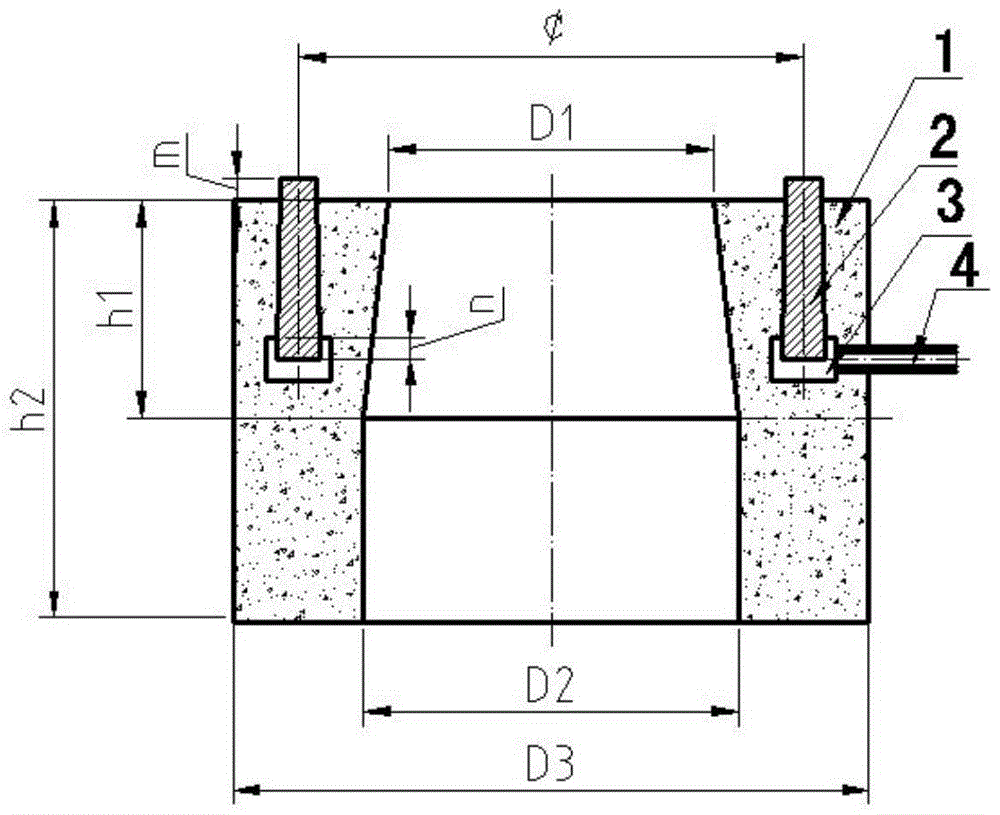

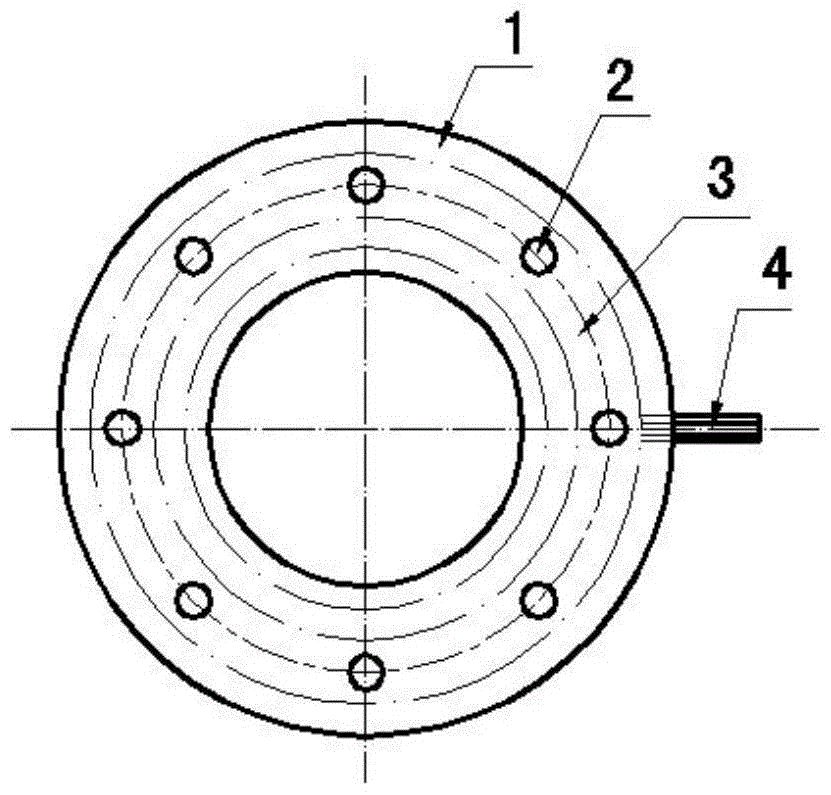

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0056] A continuous casting tundish blowing argon upper nozzle block, comprising an upper nozzle block body 1, a breathable ceramic rod 2, an air chamber box 3, and an air intake pipe 4. The middle part of the upper nozzle block body 1 is provided with a vertically penetrating In the installation hole of the upper nozzle, a plurality of circular air-permeable ceramic rods 2 uniformly arranged in the body 1 of the upper nozzle block and an annular air chamber box 3 are arranged, and the air chamber box is located in the air-permeable ceramic rod. The bottom is also in communication with the breathable ceramic rod. The side of the air chamber box 3 is connected with an air intake pipe 4. One end of the air intake pipe is connected to the side of the air chamber box 3, and the other end passes through the side of the upper nozzle block body 1. It is connected with the external connecting pipe 12; it is charac...

Embodiment 2

[0067]A continuous casting tundish blowing argon upper nozzle block as described in Example 1, the difference is that the upper end of the air-permeable ceramic rod 2 protrudes from the upper surface of the upper nozzle block body 1 to a height m of 10mm, and its lower end extends into The height n into the slot 5 on the gas chamber box is 5 mm.

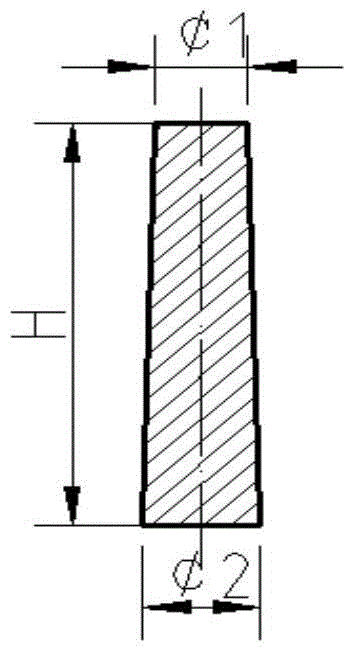

[0068] Diameter of the upper round table of the gas permeable ceramic rod 2¢ 1 18mm, the diameter of the lower round table ¢ 2 is 21mm, and the height H of the air-permeable ceramic rod is 100mm.

[0069] There are 16 air-permeable ceramic rods 2, which are uniformly arranged in a circular shape, and the diameter of the circular ring is ¢330mm.

[0070] The longitudinal section of the air chamber box 3 is rectangular, the width a is 35 mm, and the height b is 20 mm.

[0071] The upper nozzle block body 1 is cylindrical in shape with an outer diameter of D 3 400mm, height h 2 It is 190mm.

Embodiment 3

[0073] A continuous casting tundish blowing argon upper nozzle seat brick as described in Example 1, the difference is that the height m of the upper end of the breathable ceramic rod 2 protruding from the upper surface of the nozzle seat brick body is 15mm, and the lower end extends into the air chamber The height n in the slot 5 of the box is 10 mm.

[0074] Diameter of the upper round table of the gas permeable ceramic rod 2¢ 1 18mm, the diameter of the lower round table ¢ 2 is 20mm, and the height H of the breathable ceramic rod is 95mm.

[0075] There are 12 air-permeable ceramic rods 2, which are evenly arranged in a ring shape, and the diameter of the ring is ¢320mm.

[0076] The longitudinal section of the air chamber box 3 is rectangular, the width a is 30 mm, and the height b is 20 mm.

[0077] The upper nozzle block body 1 is cylindrical in shape with an outer diameter of D 3 380mm, height h 2 It is 203mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com