Laser cutting method for garment production

A laser and clothing technology, applied in the field of clothing production, can solve problems such as the inability to effectively eliminate fabric wrinkles, reduce the performance of laser cutting machines, and reduce the efficiency of laser cutting processing, so as to achieve a convenient laying process and improve cutting efficiency. , safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

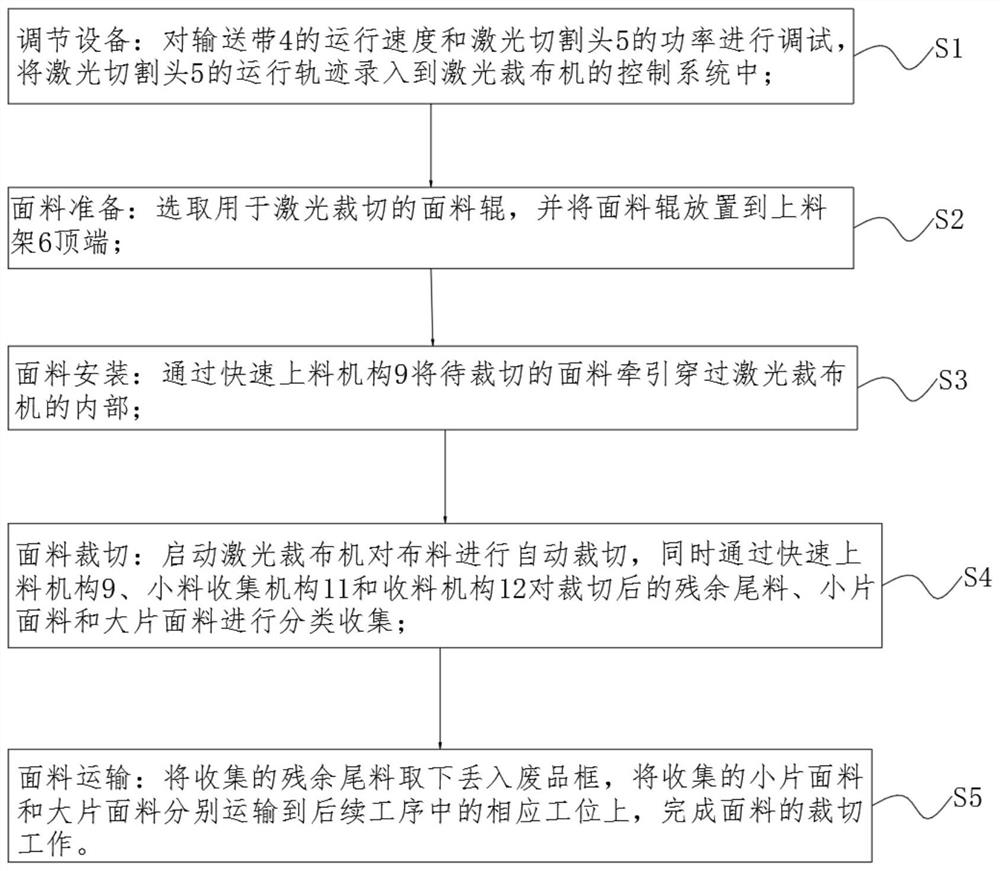

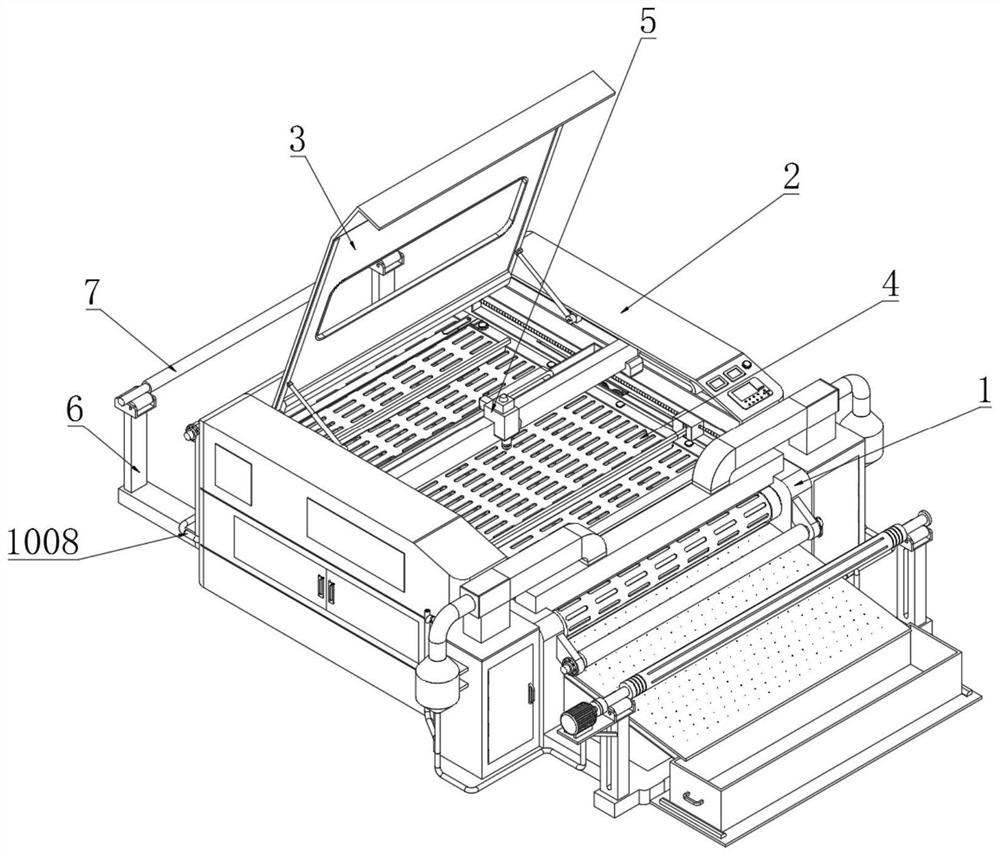

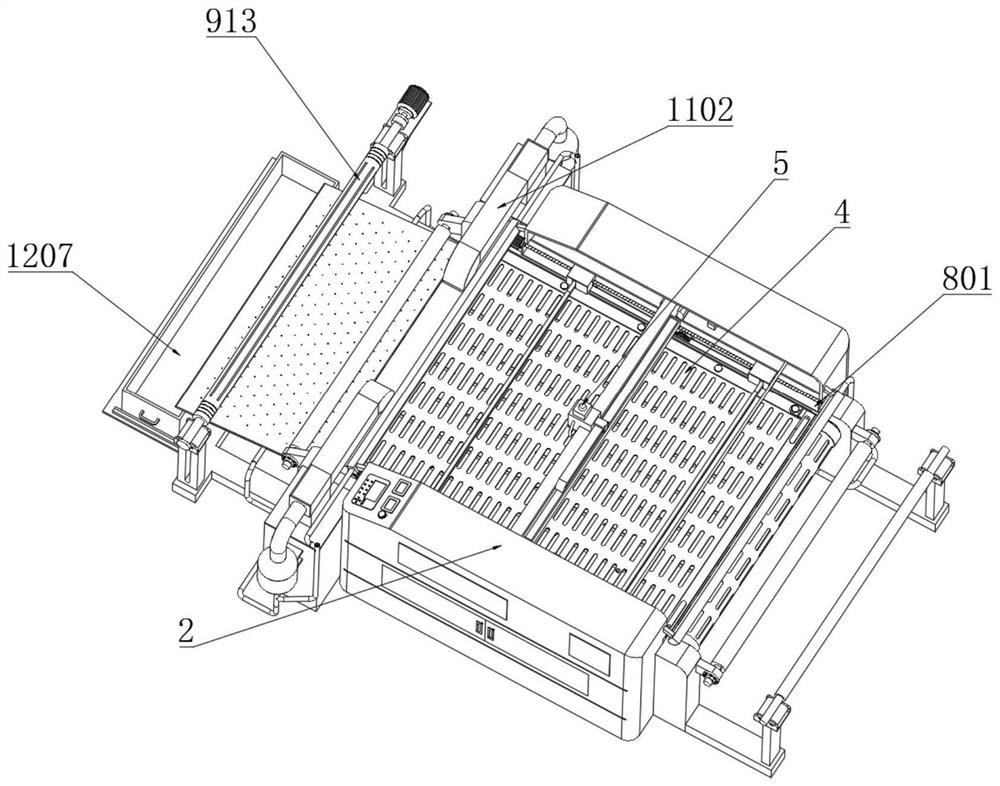

[0044] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a laser cutting method for garment production, comprising the following steps;

[0045] S1. Adjusting equipment: debug the running speed of the conveyor belt 4 and the power of the laser cutting head 5, and input the running track of the laser cutting head 5 into the control system of the laser cloth cutting machine;

[0046] S2, fabric preparation: select the fabric roll for laser cutting, and place the fabric roll on the top of the feeding rack 6;

[0047] S3. Fabric installation: pull the fabric to be cut through the interior of the laser cutting machine through the fast feeding mechanism 9;

[0048] S4. Fabric cutting: Start the laser cloth cutting machine to automatically cut the fabric, and at the same time pass the fast feeding mechanism 9, the small material collecting mechanism 11 and the material receiving mechanism 12 for the remaining tails, small pieces of fabric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com