Method for preventing hydraulic bracket in large inclined angle workface from collapsing

A technology of hydraulic support and working face, which is applied to mine roof support, earth-moving drilling, mining equipment, etc., can solve the problems of support dumping, high labor intensity and unrealistic roof connection, so as to maintain the stability of the roof and simplify the mesh laying process. , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

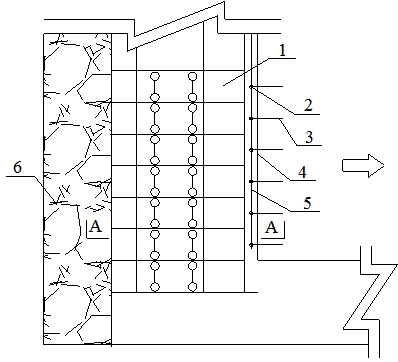

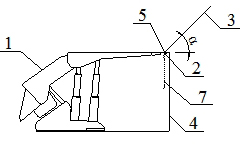

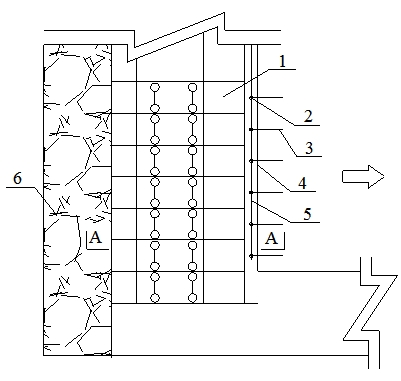

[0016] as attached figure 1 As shown, the anti-falling method of the large-inclination working face hydraulic support of the present invention: first, in the middle of each hydraulic support 1 of the coal mining face, an anchor rod 3 is tilted along the roof to the direction of the coal wall 4, and the anchor rod 3 is the whole Thread equal-strength bolts, the length of which is not less than 2.2m and the diameter of not less than 18mm, the angle α between the bolt 3 and the top plate of the coal wall 4 is 40°~50°; The exposed ends of each anchor rod 3 are connected in series, and then the wire mesh 7 is hung on the steel wire rope 5 connected in series, as attached figure 2 As shown; when the hydraulic support 1 moves forward, the suspended metal mesh 7 is jacked up and attached to the front beam of the hydraulic support 1, and as the coal mining face a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com