Three-layer-timber-structure solid wood floor and installment method of the same

A technology of solid wood flooring and wood, applied in the direction of chemical instruments and methods, layered products, building structures, etc., can solve the problems of limited floor width, prone to uplift, cracking, floor heating equipment cannot be laid, etc., to achieve disassembly and repair Convenience, simple laying process, saving materials and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

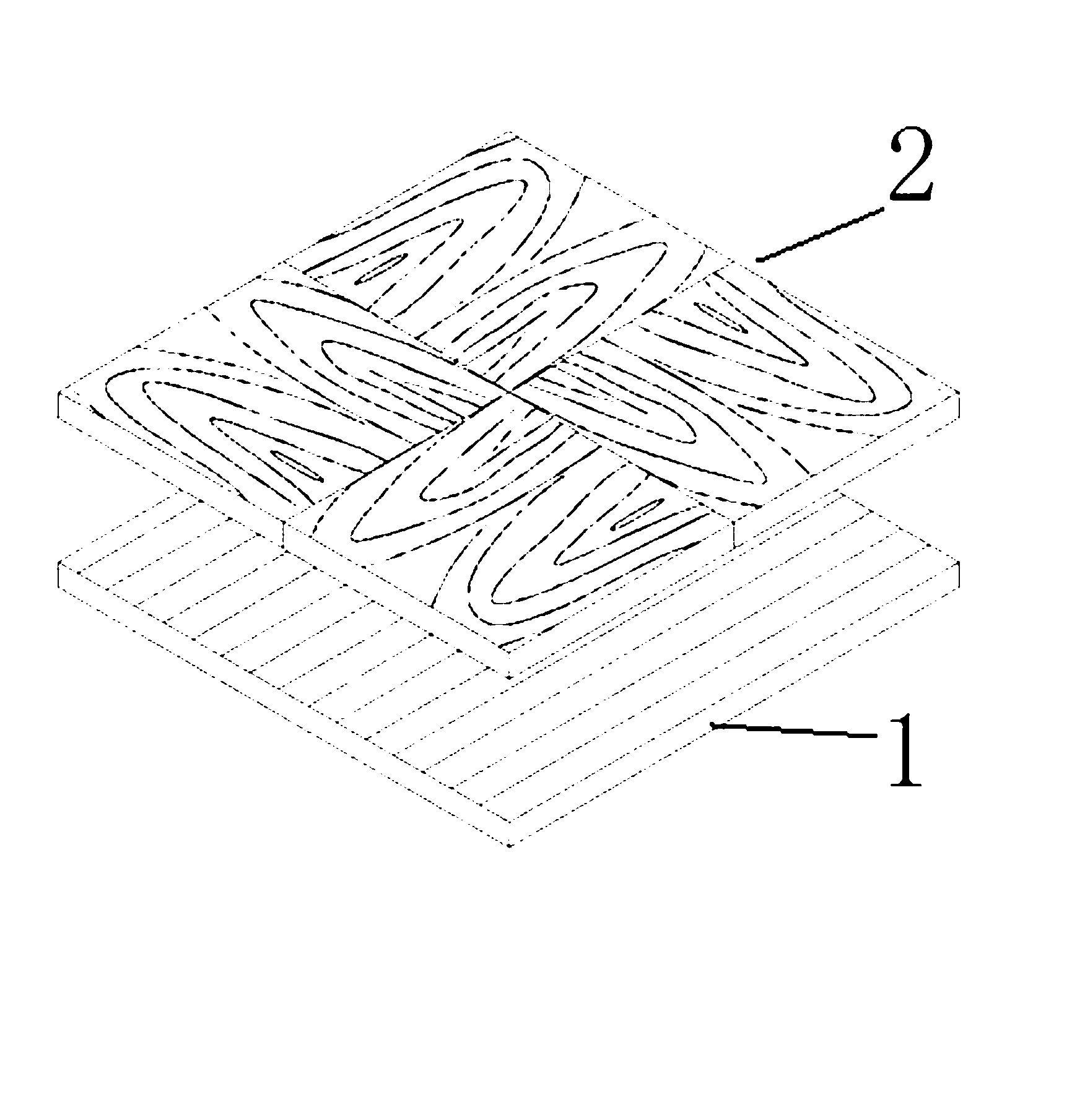

[0020] Lay the first square floor at a distance of 10-12mm from the wall or building components. The size of the square floor is 300mm*300mm, and straighten it with a straight line; Lay through U-shaped metal buckles between them; repeat the above steps until the floor is installed, and install compression springs at the interval between the wall or building components and the floor.

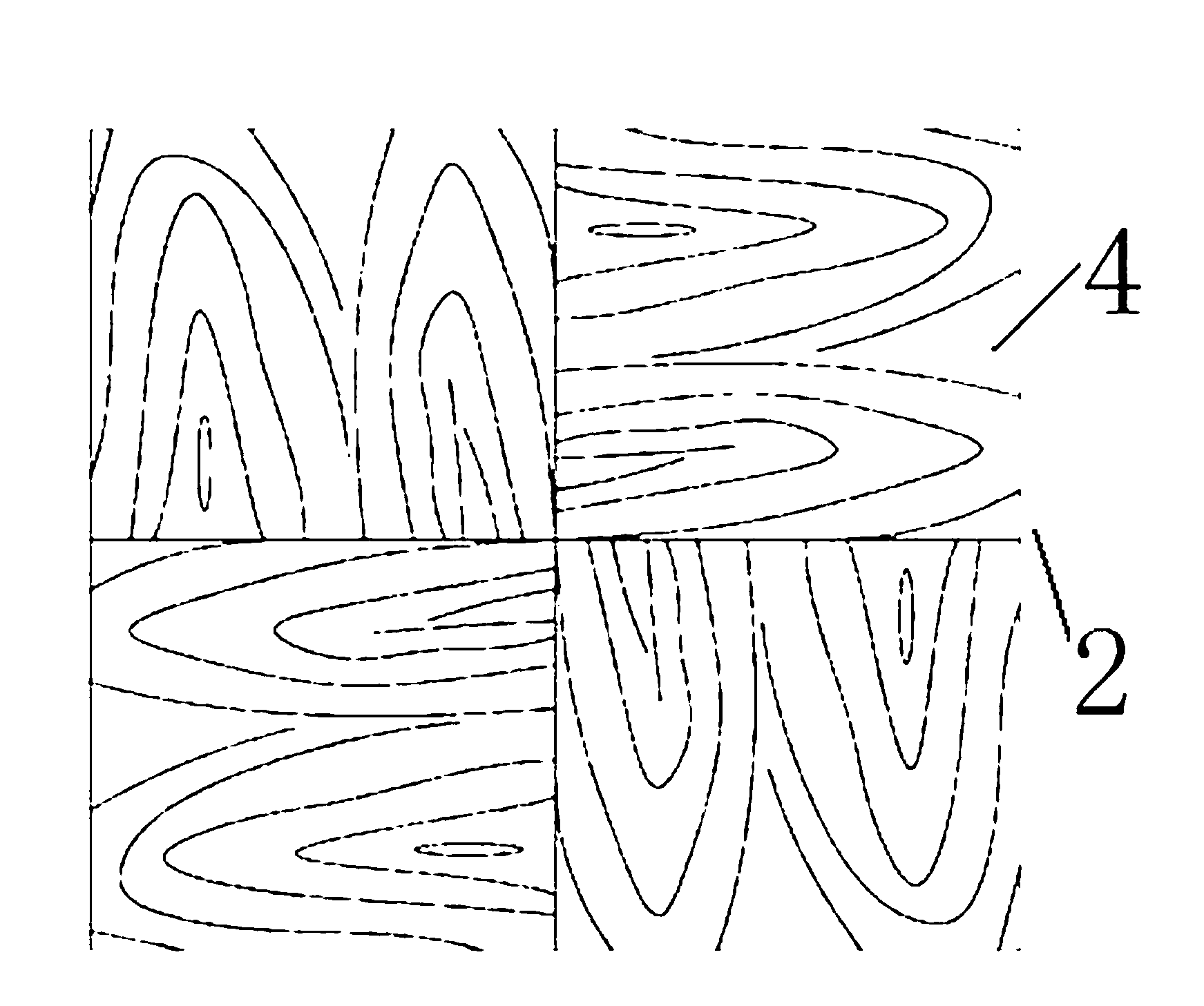

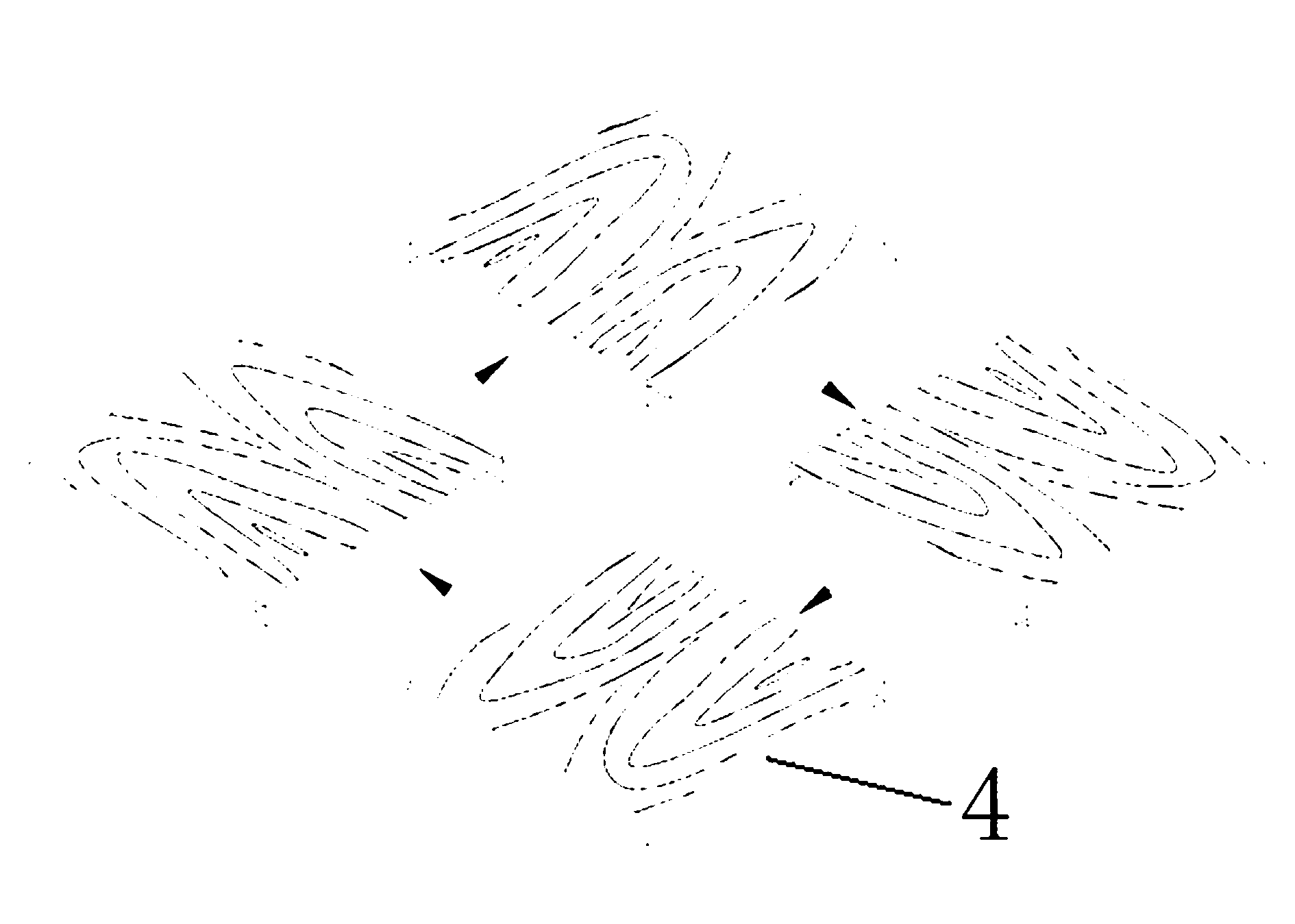

[0021] A square floor is composed of a bottom plate, a middle plate and a panel, and the middle plate and the middle plate are spliced by four floor boards (see image 3 ), the wood texture between adjacent floor boards is criss-crossed, so that the wood texture of the whole middle board is separated, and the bottom board is bonded to the middle board in the forward and reverse direction (horizontal or vertical), The so-called forward and reverse direction means that 50% of the wood grain of the bottom plate is along the wood grain direction of the middle plate, and 50% is against the wood gra...

Embodiment 2

[0023] Lay the first square floor at a distance of 10-12mm from the wall or building components. The size of the square floor is 800mm*800mm, and straighten it with a straight line; Lay through U-shaped metal buckles between them; repeat the above steps until the floor is installed, and install compression springs at the interval between the wall or building components and the floor.

[0024] A square floor is composed of a bottom plate, a middle plate and a panel, and the middle plate and the middle plate are spliced by four floor boards (see Figure 4 ), the wood texture between adjacent floor boards is criss-cross, so that the wood texture of the whole middle board is separated, and the bottom board is combined with the middle board by the oblique and inverse method. The so-called oblique and inverse method is the bottom board The direction of the wood texture and the direction of the wood texture of the middle board form an oblique angle of 45 degrees, so that the whole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com