Ground surface finishing method

A ground and mortar technology, applied in the field of decoration, can solve the problems of lack of individuality, impact on health, complex decoration methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

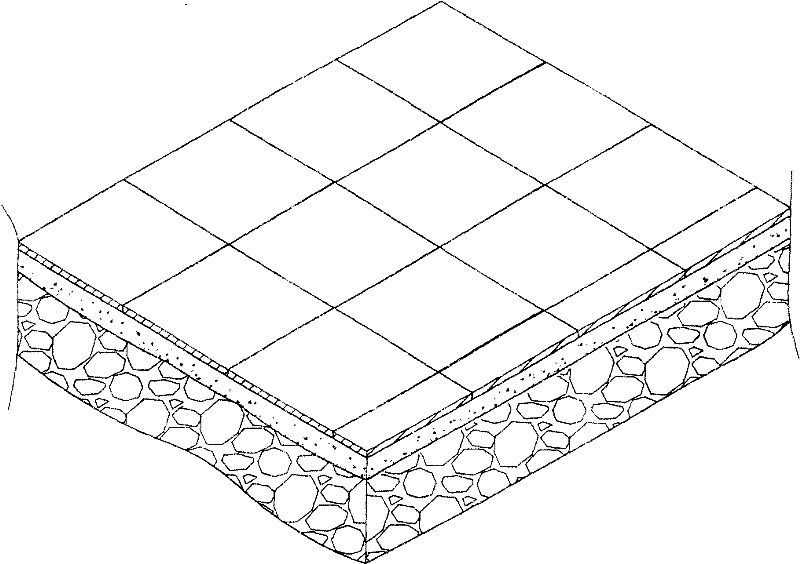

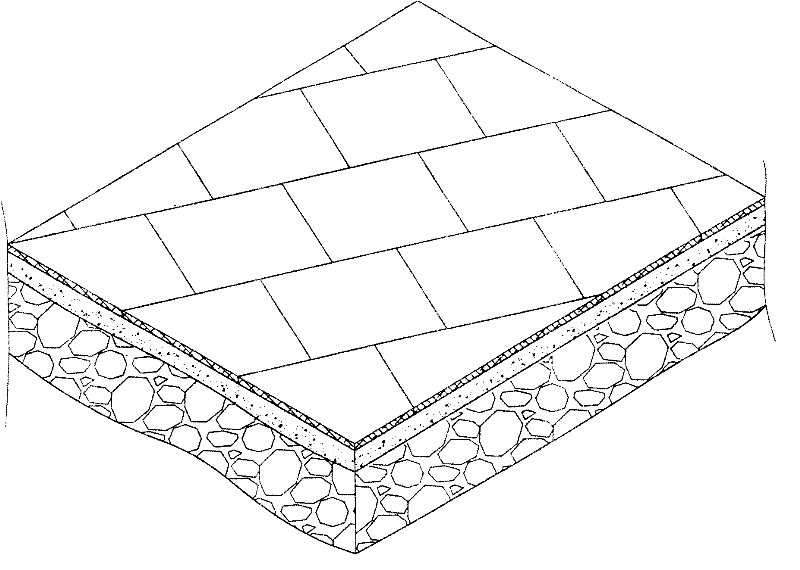

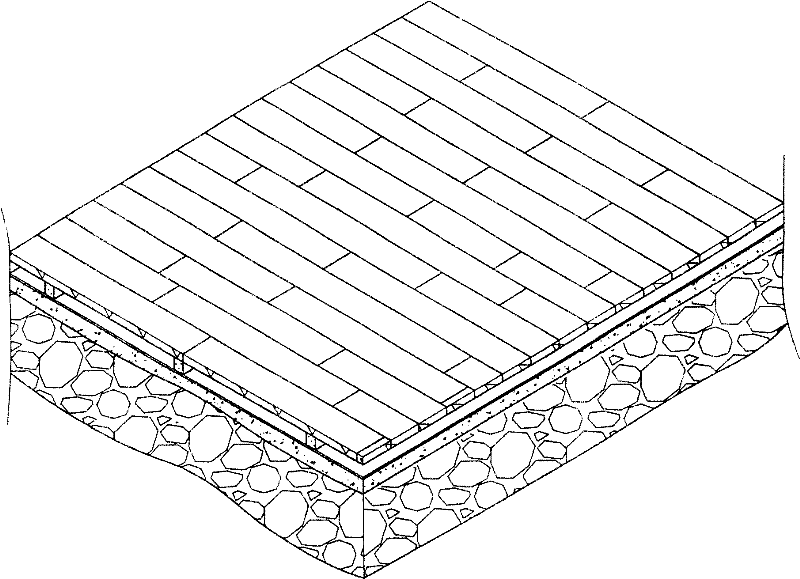

[0025] Such as Figure 6 As shown, it is the ground decoration method disclosed by the present invention. The present invention measures the flatness of the construction site before concrete construction, as before the decoration of tiles, etc., sets up the horizontal elevation point, marks the elastic line, and seals the gap as a mark. Anti-leakage treatment of materials, and then start the ground decoration construction, cooperate with Figure 4 Shown:

[0026] Stir and mix the self-leveling mortar and water at a ratio of 5:1 first. Among them, the self-leveling mortar is prepared by the following substances by weight percentage: Portland cement 52.5R 20-25%, high alumina cement 5-10%, flow enhancer 1-2%, calcium carbonate (50-100 microns) 15-25%, silica sand (0.1-0.5 mm) 30-50%, early strength agent 0.5-1%, retarder 0.5-1%, quicklime 1-3%, redispersed latex powder 2-4%, water retention agent 0.5-1%, defoamer 0.5-1%. Specifically, high-hardening melamine can be selected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com