Heating layer for megawatt wind turbine blade auxiliary mould and manufacturing method thereof

A wind power blade and megawatt-level technology, which is applied to the heating layer of the auxiliary mold of the megawatt-level wind power blade and its production field, can solve the problems that the electric heating wire cannot work normally, the detection of the fuse position is difficult, and the normal production is affected. The effect of safe and reliable temperature control, low production cost and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

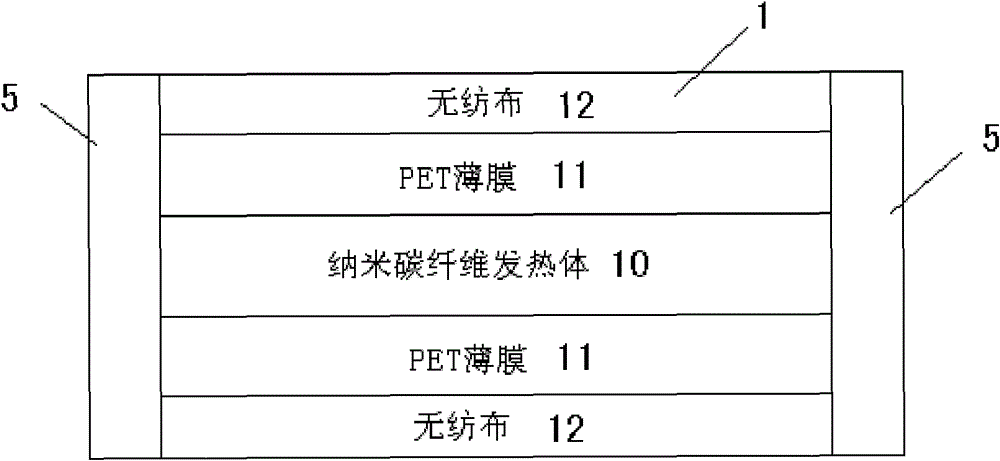

[0019] The heating layer of the megawatt-level wind power blade auxiliary mold of the present invention is located between the inner structure layer and the outer structure layer of the blade auxiliary mold, and according to the shape of the blade auxiliary mold, the nano-carbon heating film of the heating layer is placed according to the profile of the laying position The width is pre-cut, and each piece of nano-carbon heating film is numbered, which can ensure that each piece of nano-carbon heating film corresponds to the position where it is laid, and ensures that the girder and shear web products and flanges are in the blade auxiliary mold Uniform heating during curing.

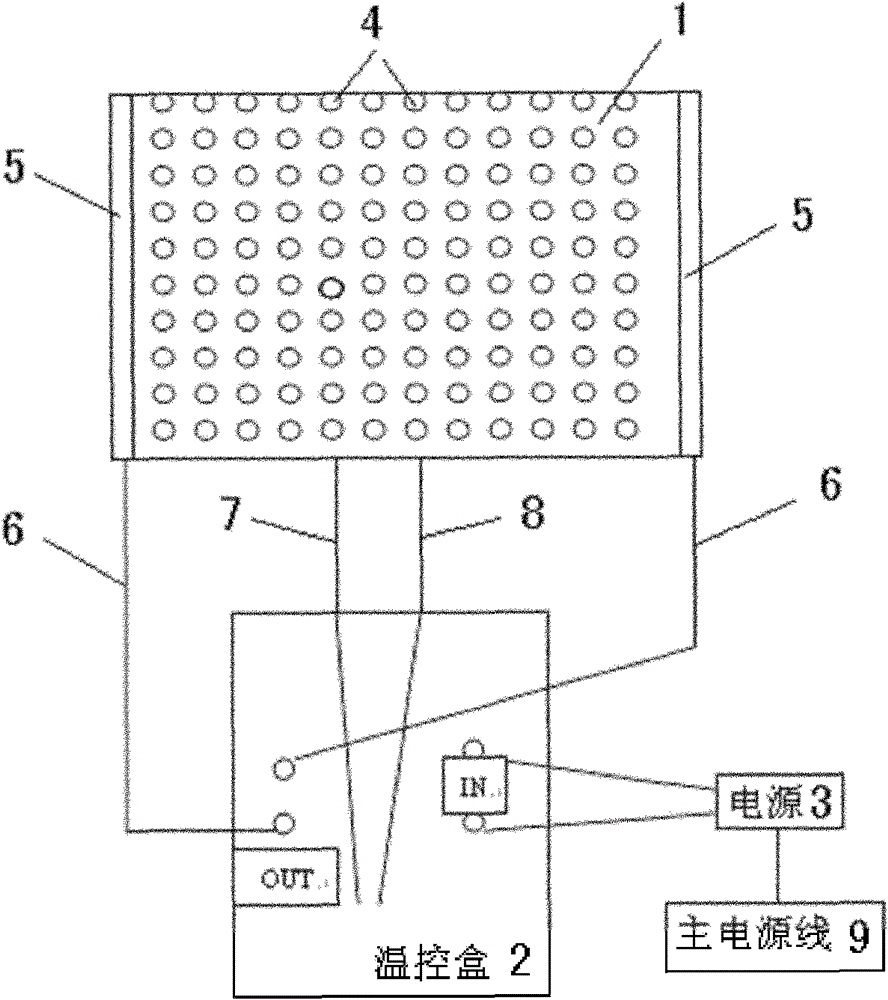

[0020] like figure 1As shown, the heating layer of the present invention includes at least one heating zone, and each heating zone includes 5 to 15 nano-carbon heating films 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com