Cold-coating asphalt, and preparation method and construction method thereof

A construction method and asphalt technology, applied in asphalt coatings, coatings, epoxy resin coatings, etc., can solve the problems of toxicity, impossibility of normal temperature construction, and impossibility of cold coating, etc., so as to simplify the pavement paving process, increase the paving speed and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

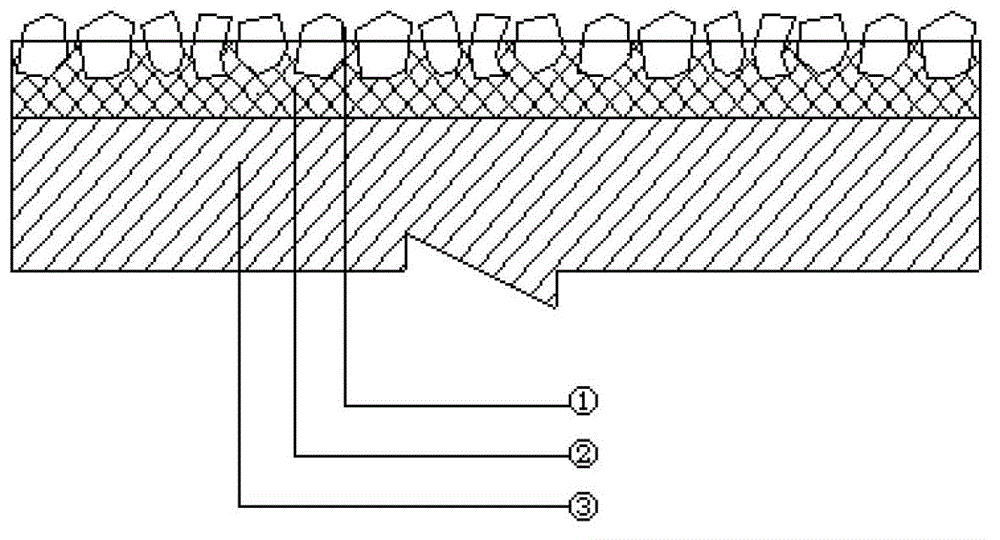

Image

Examples

Embodiment 1

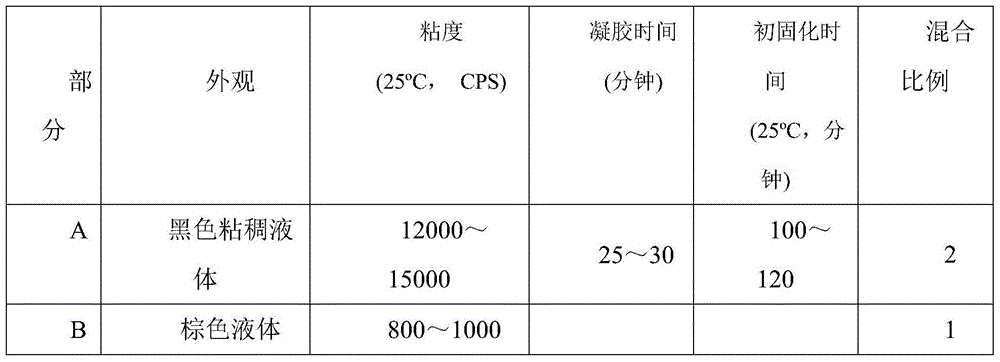

[0039] The cold-coated asphalt of this embodiment includes part A and part B. The mass ratio of part A to part B is 2:1. In part A: No. 90 petroleum pitch (Maoming Petrochemical petroleum pitch): 25 parts by weight; bisphenol A 50 parts by weight of epoxy resin (Hongchang Electronic Materials Co., Ltd., GELR-128), 25 parts by weight of naphthenic acid (Jiangxi Dongchuan Chemical Co., Ltd., refined naphthenic acid); Part B: Fatty amine curing agent: 50 parts by weight Copies

[0040] Preparation method: The preparation method of Part A is as follows: heat the reactor to 100~120℃, add the active modifier naphthenic acid and No. 90 petroleum pitch in sequence, stir until the pitch is completely melted, and then add the reactive resin after mixing. Bisphenol A epoxy resin, disperse and stir at high speed until it is evenly mixed. When preparing Part A, various well-known additives such as defoamers, stabilizers and dispersants can be added in appropriate amounts without changing the...

Embodiment 2

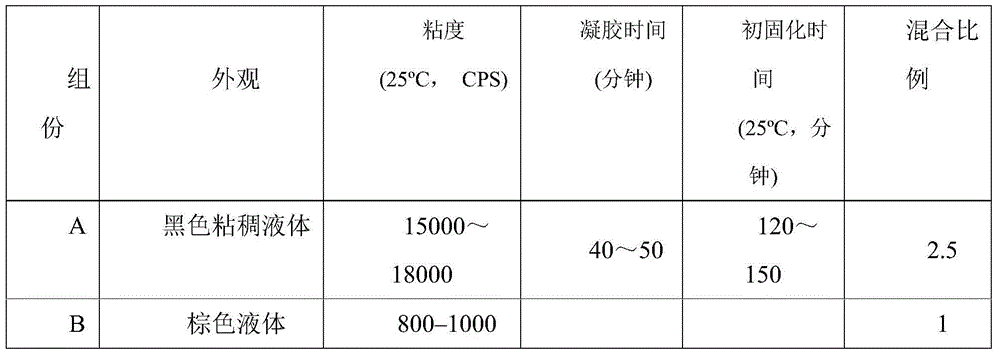

[0044] The cold-coated asphalt of this embodiment includes part A and part B. The mass ratio of part A to part B is 2.5:1. In part A: No. 90 petroleum pitch (Maoming Petrochemical petroleum pitch): 30 parts by weight; bisphenol F 40 parts by weight of epoxy resin (Hongchang Electronic Materials Co., Ltd., GELR-128), 30 parts by weight of naphthenic acid (Jiangxi Dongchuan Chemical Co., Ltd., refined naphthenic acid); Part B: aromatic amine curing agent: 40 parts by weight Copies

[0045] Preparation method: The preparation method of Part A is: heating the reactor to 100~120℃, adding the active modifier naphthenic acid and No. 90 petroleum pitch in sequence, stirring until the pitch is completely melted, and then adding the reactive resin after mixing. Bisphenol A epoxy resin, disperse and stir at high speed until it is evenly mixed. When preparing Part A, various well-known additives such as defoamers, stabilizers and dispersants can be added in appropriate amounts without chang...

Embodiment 3

[0049] The cold-coated asphalt of the present invention includes part A and part B, wherein the mass ratio of part A to part B is 1.5:1. In part A: No. 70 petroleum pitch (Maoming Petrochemical petroleum pitch): 10 parts by weight; phenolic epoxy resin 60 parts by weight (Hongchang Electronic Materials Co., Ltd., GELR-128), 30 parts of naphthenic acid (Jiangxi Dongchuan Chemical Co., Ltd., refined naphthenic acid); Part B: alicyclic amine curing agent: 60 parts by weight;

[0050] Preparation method: The preparation method of Part A is as follows: heating the reactor to 100-120°C, adding active modifier and asphalt in sequence and stirring until the asphalt is completely melted and mixed uniformly, then adding the reactive resin, dispersing and stirring at high speed until the mixing is uniform. When preparing component A, various well-known additives such as defoamers, stabilizers and dispersants can be added in appropriate amounts without changing the physical properties of comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com