Multifunctional simulation engine for adiabatic layer ablation test

A technology of ablation test and thermal insulation layer, which is applied in the field of aerospace science, can solve the problems of single test device, reduce the negative mass of adiabatic design part, and cannot be divided into understanding, etc., and achieve the effect of ensuring flight safety performance, reducing negative mass and optimizing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

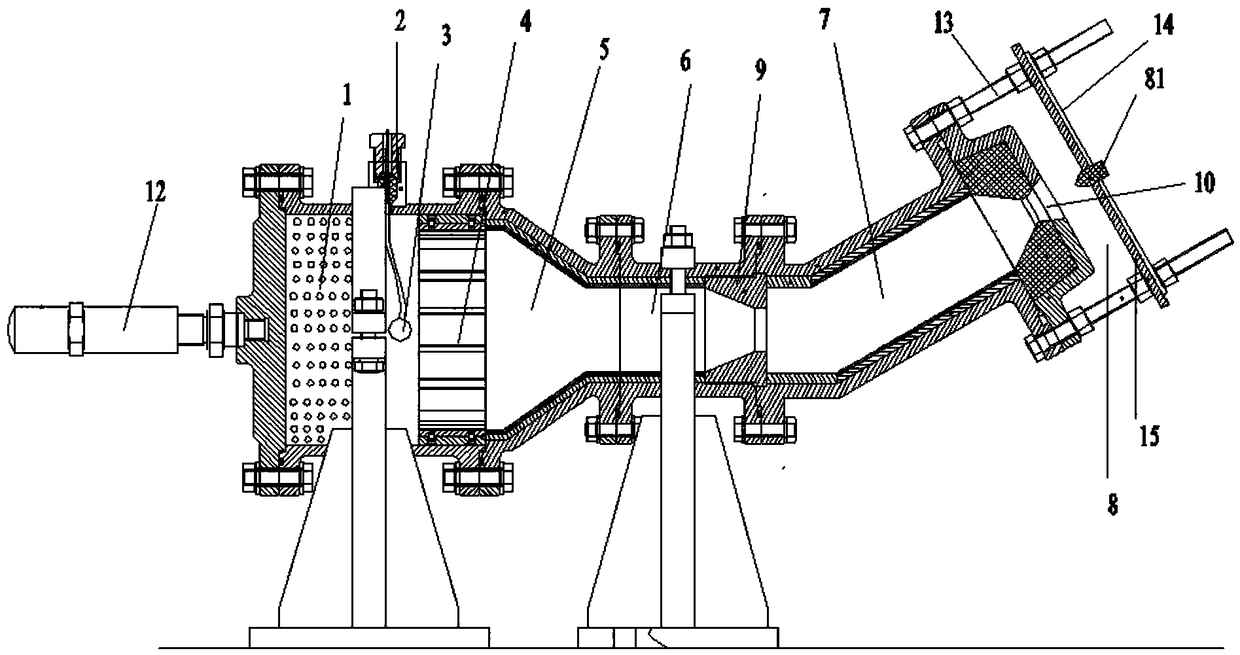

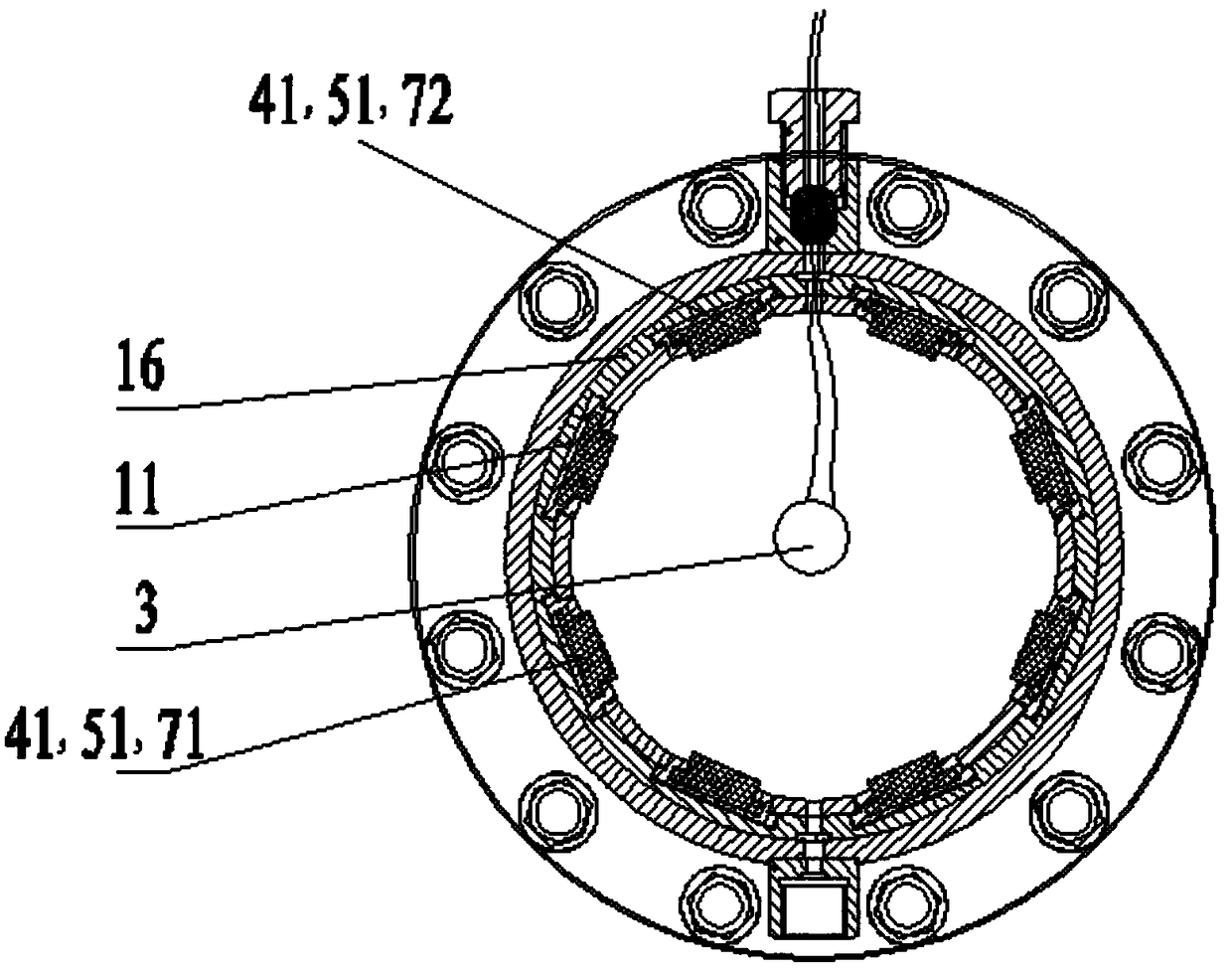

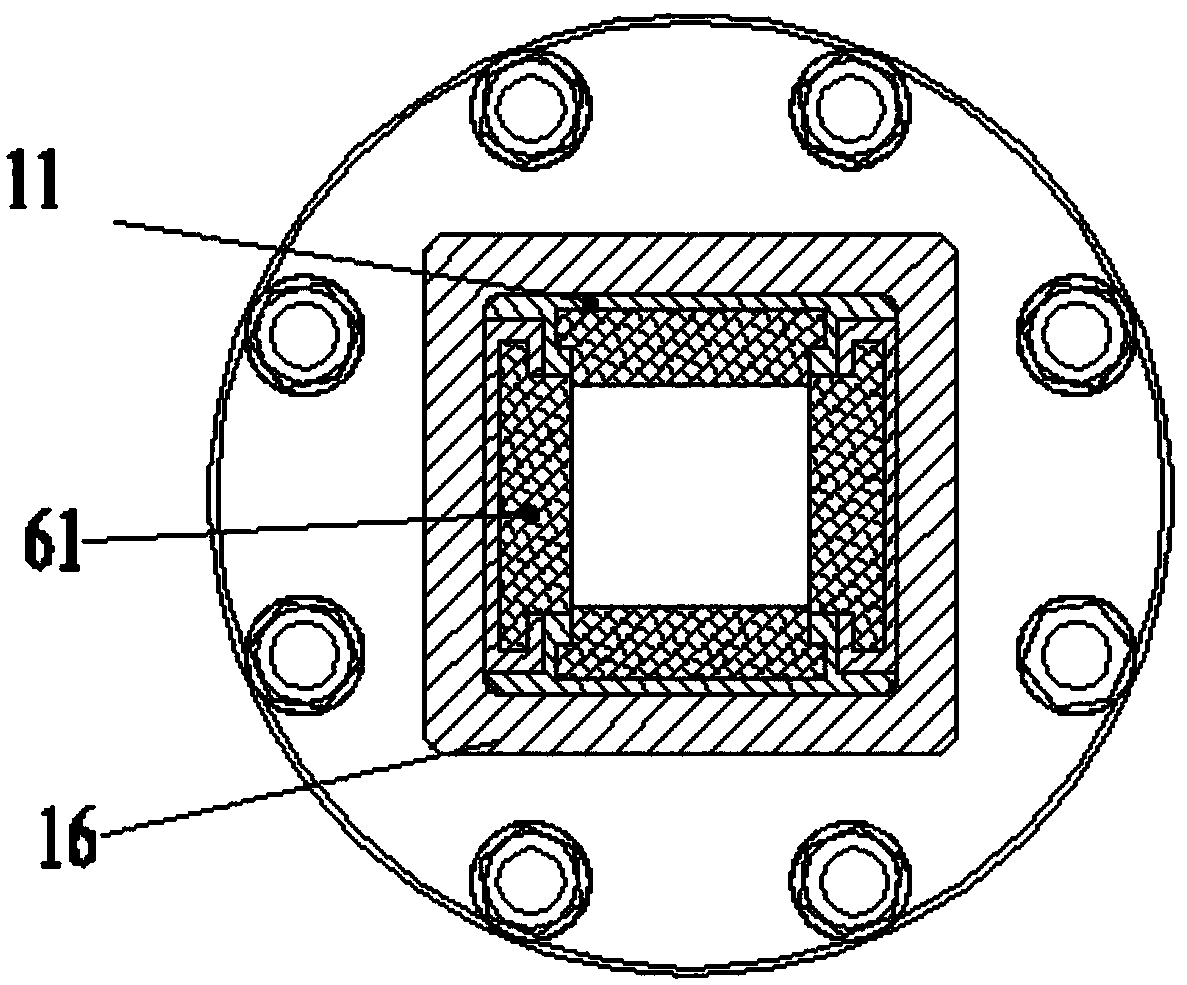

[0032] The invention discloses a multifunctional simulation engine for the ablation test of the heat insulation layer, such as figure 1 As shown, it includes a gas generator 2 for burning a solid propellant 1, a gas generator 2 with a solid propellant 1 and an igniter 3 inside, the engine combustion chamber diameter of the gas generator 2 is 200mm, and the gas generator 2 The propellant 1 and the igniter 3 for igniting the propellant 1 are arranged inside, the igniter 3 is located next to the center of the propellant 1, one end of the gas generator 2 is sealed, and the closed end of the gas generator 2 is connected with a The front head push rod 12 of the gas generator 2, and the other end of the gas generator 2 are connected with the low-speed section 4, the medium-speed section 5, the high-speed section 6, the overload section 7 and the plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com