Tubular inner-hole charge structure with inner cavity partition and used for solid rocket engine, and method

An inner cavity partition, solid rocket technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of increasing the design thickness of the engine combustion chamber shell, increasing the passive weight of the missile, and affecting the missile range, etc. Achieve the effect of reducing draft risk, reducing negative quality and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

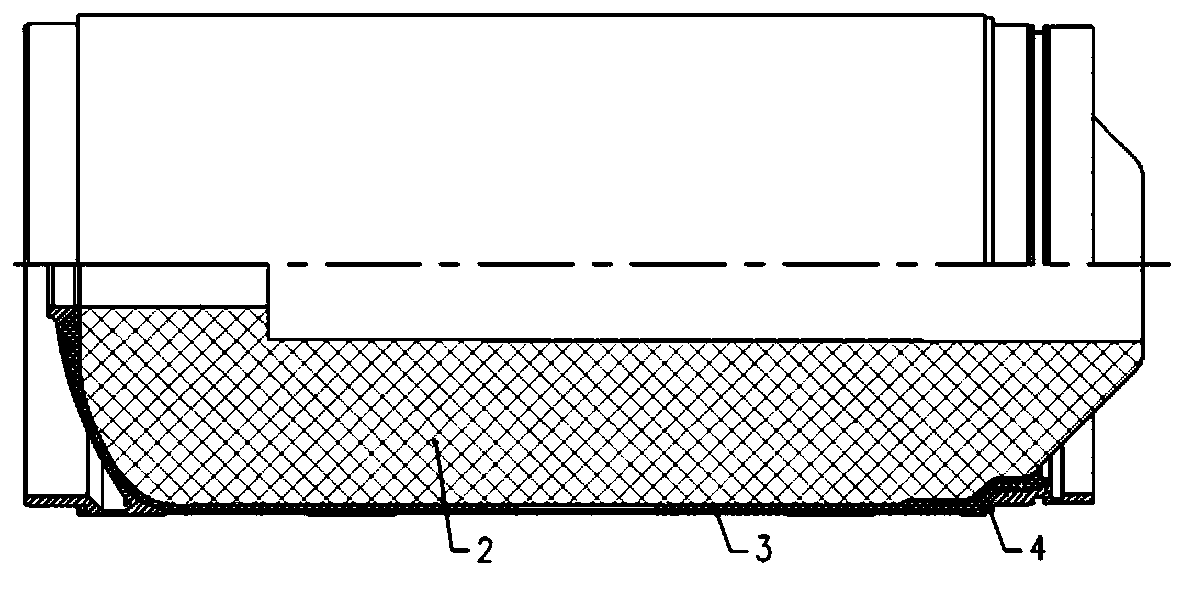

[0027] The solution provided by the present invention is to provide a solid rocket motor inner hole tubular charge structure with an inner cavity partition, and an inner cavity partition is arranged in the solid rocket combustion chamber charge column, which improves the surface increase of the charge, Make the working pressure and thrust of the engine stable.

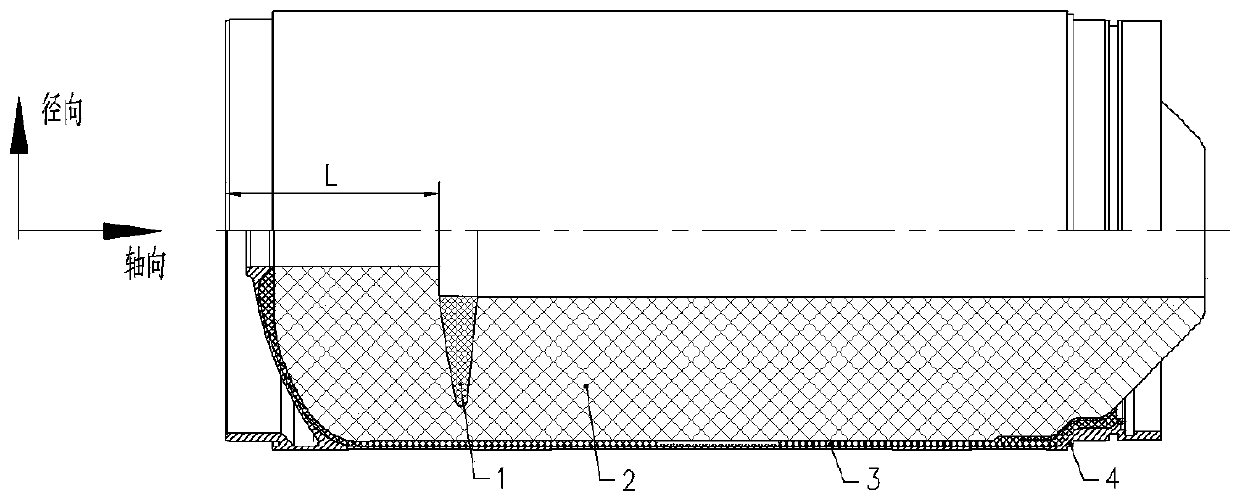

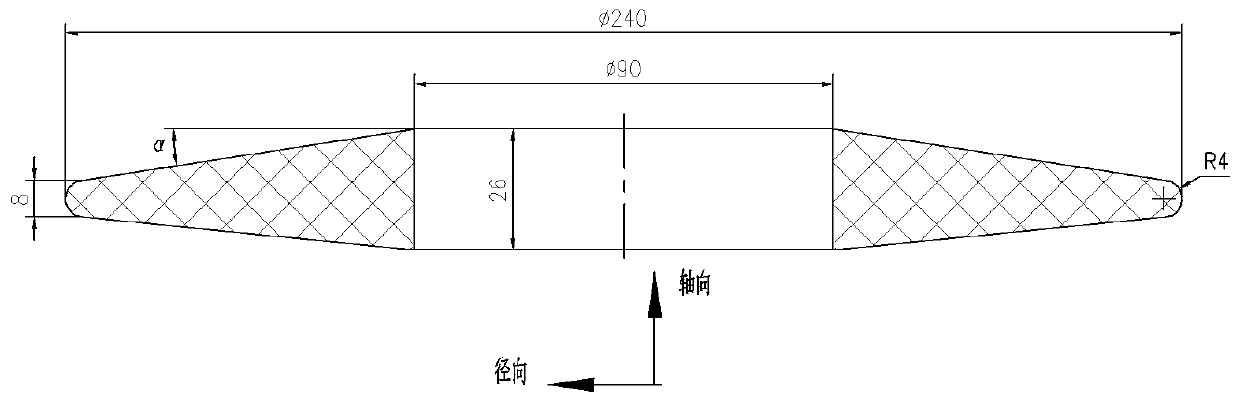

[0028] Such as figure 1 As shown, the present invention proposes a solid rocket motor inner hole tubular charge structure with an inner cavity partition, including an inner cavity partition 1, a heat insulating layer 3 and a combustion chamber casing 4;

[0029] The inner surface of the combustion chamber shell 4 is sandblasted, and the adhesive is evenly sprayed, and the heat insulation layer 3 is bonded to the combustion chamber shell 4; Put the butylated hydroxy composite propellant slurry, and when the slurry reaches the designated position, put it into the inner cavity partition 1, and then continue to inject th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com