Automatic preparation method of moistening agent

An automatic preparation and sizing technology, which is applied to chemical instruments and methods, mixer accessories, dissolution, etc., can solve the problems of high labor intensity, high labor intensity, and error-prone discharge, so as to ensure the feeding sequence and weighing accuracy , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the content of the patent of the present invention, the technical solutions of the present invention will be further described through specific examples below, but the present invention is not limited to the examples.

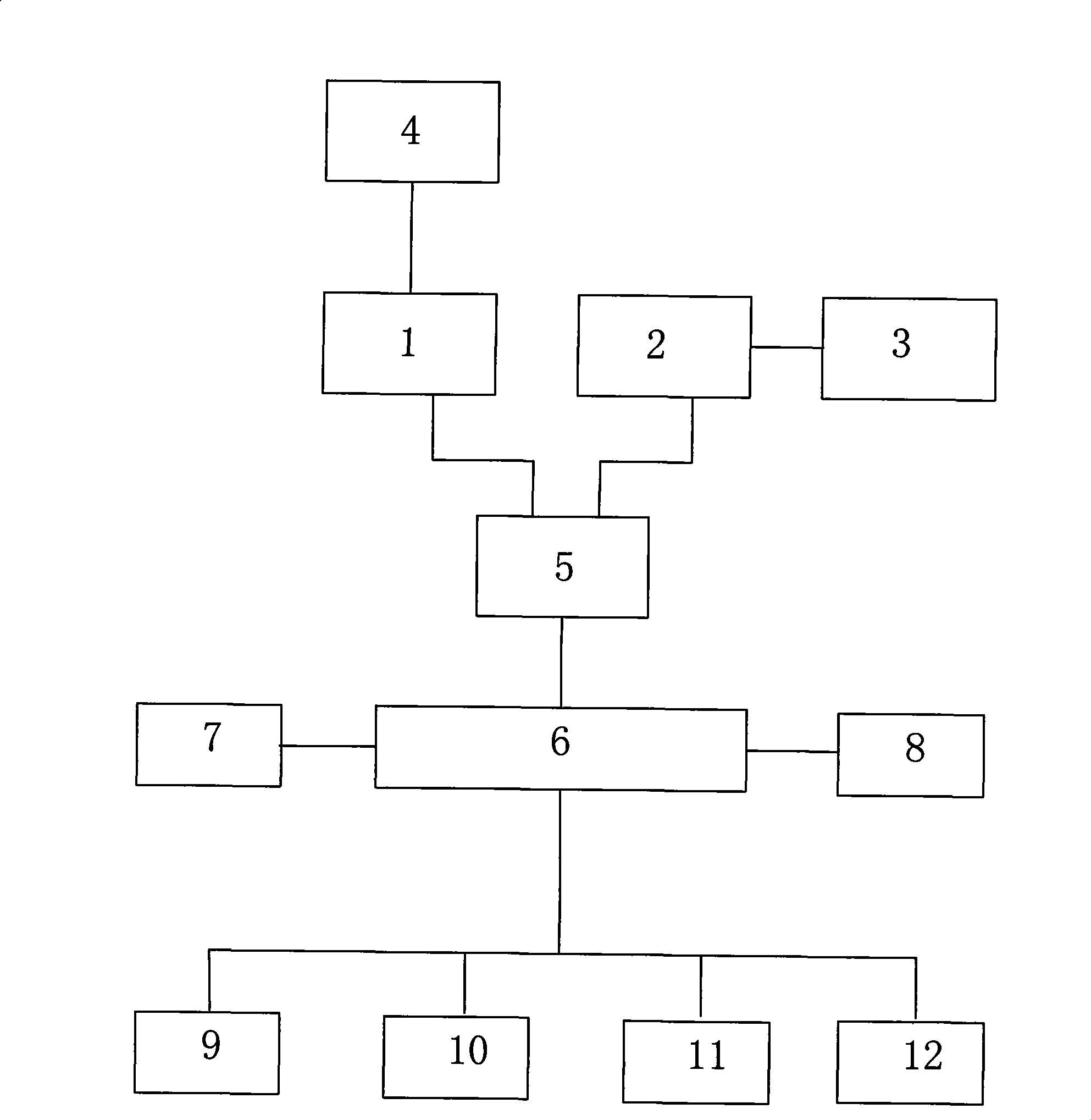

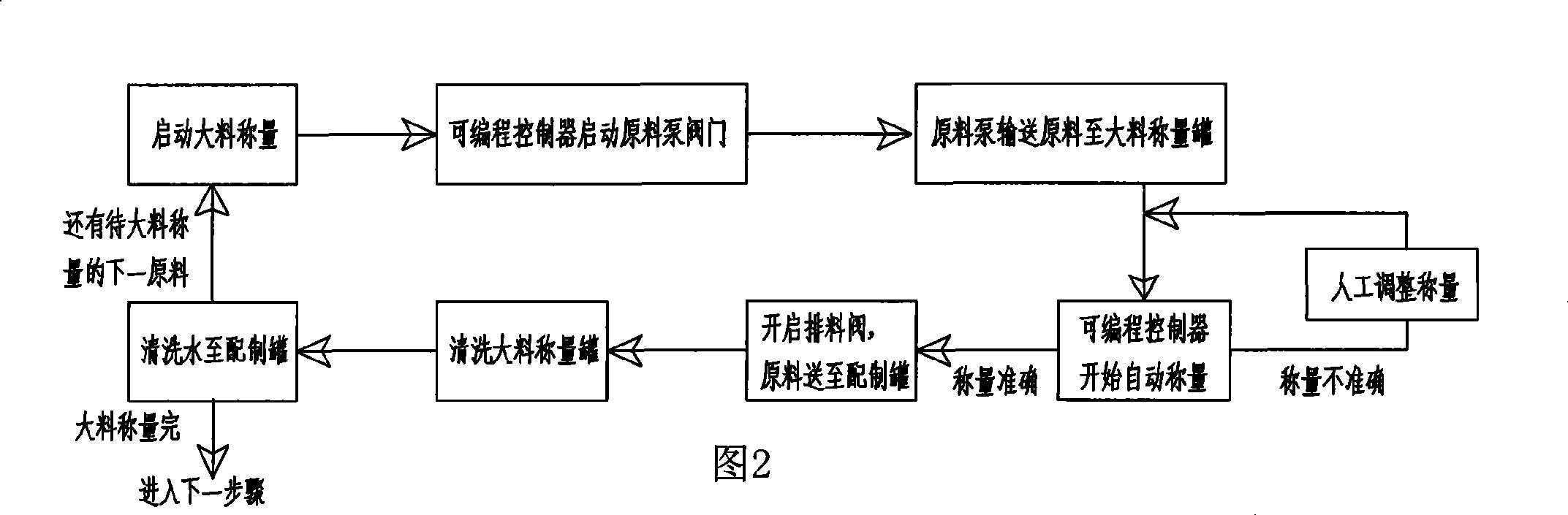

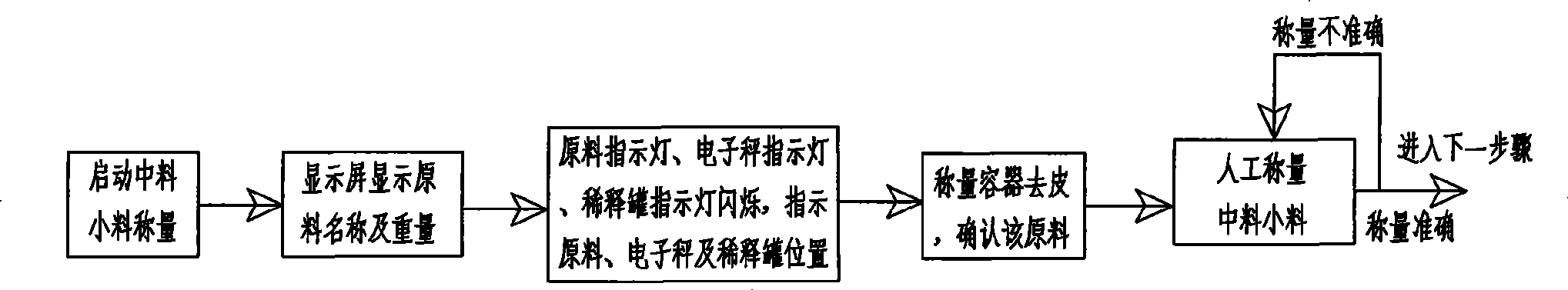

[0017] see Figure 1 ~ Figure 3 , the embodiment of the present invention is provided with computer control system, small material weighing balance 7, large material weighing tank and low storage tank weighing instrument 8, agitator 9, self-control valve 10, preparation tank weighing instrument 11, middle material weighing instrument Measuring platform scale 12 and several weighing tanks, dilution tanks, preparation tanks, low storage tanks, containers, microwave rapid detectors, PH meters; computer control system includes server 1, operator station terminal 2, printer 3, display screen and indicator lights 4. Ethernet 5, programmable controller 6; weighing equipment includes small material weighing balance 7, large material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com