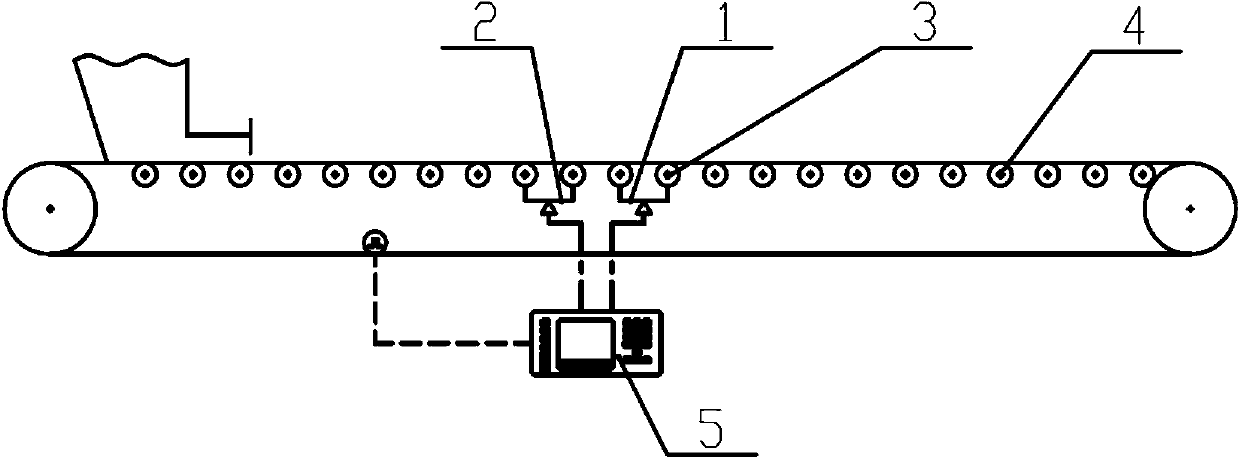

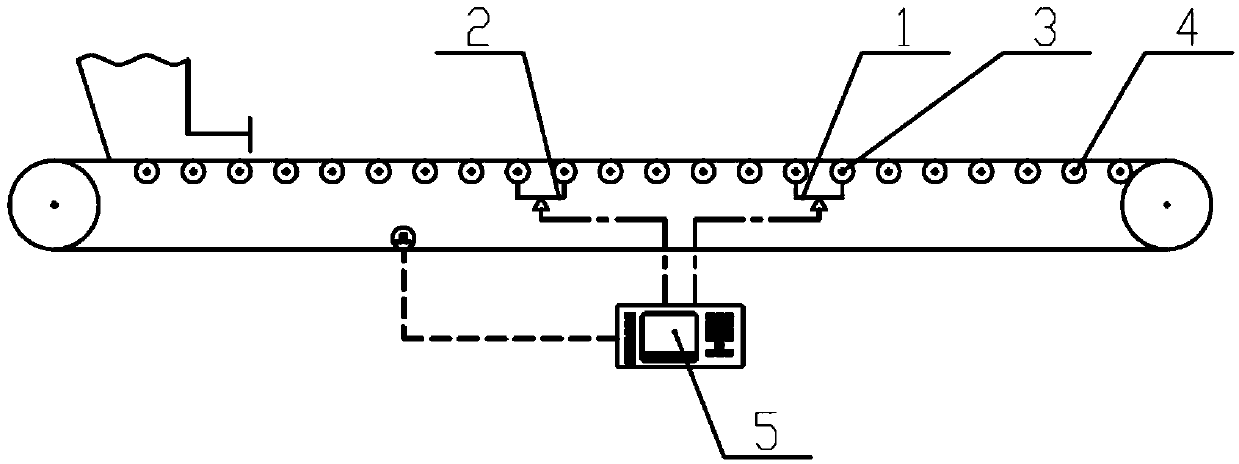

Linear compensation method for electronic belt scale

An electronic belt scale, linear compensation technology, applied in measuring devices, instruments, weighing and other directions, can solve the problems of poor weighing accuracy, high operating cost and high investment, achieve convenient linear compensation, ensure weighing accuracy, overcome the system Effects of Linearity Error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0035] Test conditions: belt width: 1000mm; belt speed: 2.0m / s; maximum material flow rate of the belt conveyor: M = 1000t / h.

[0036] Step 1: During material calibration of the belt scale, the weighing instrument 5 calculates and records:

[0037] Number of belt scale range calibrations after material calibration: E=8795021;

[0038] The force value of weighing scale frame 1 before measurement: a=98t;

[0039] After measuring, weigh the force value of the scale frame 2: b=100t;

[0040] Force error: A=(b-a) / b=(100-98) / 100=0.02;

[0041] The measurement accuracy of the belt scale material after calibration is: ±0.5%.

[0042] Step 2: When the belt scale is running normally and the zero point is adjusted, in the empty belt state, the weighing instrument 5 calculates and records:

[0043] The force value of weighing scale frame 1 before measurement: c=1.3t;

[0044] The force value of weighing scale frame 2 after measurement: d=1.5t;

[0045] Force error: B=(d-c) / d=(1.5-1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com