Blast furnace under-groove coke weighing control system without dispersing hopper

A technology of control system and blast furnace tank, which is applied in the field of coke weighing control system under the blast furnace tank, can solve the problems that the weighing control system is not fully applicable or not applicable, so as to prolong the service life, ensure the weighing accuracy and ensure the accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

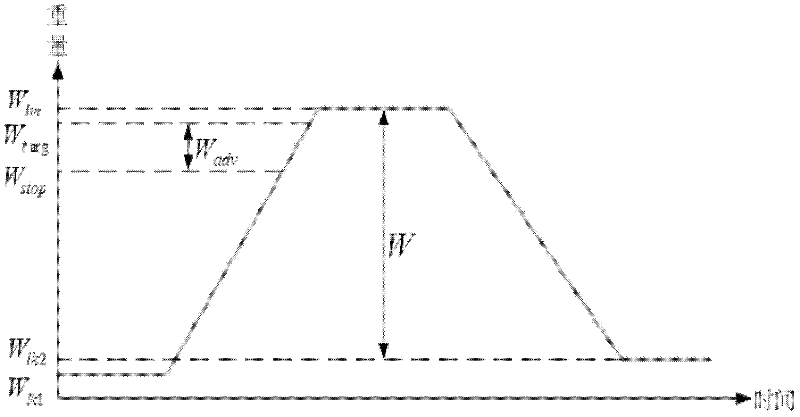

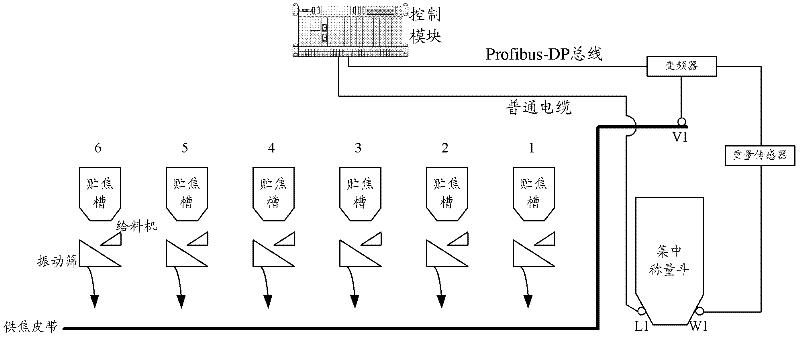

[0029] Such as figure 2 As shown, the coke weighing control system under the blast furnace tank without a dispersing hopper provided by the embodiment of the present invention includes a control module, a frequency converter, a storage tank, a centralized weighing hopper, a speed sensor, a feeder and a vibrating screen. The control module is used to sequentially control the stop of the feeder, the vibrating screen and the coke belt, so as to distribute the materials stored in the storage tank to the centralized weighing hopper. The control module can be implemented with DSP, ARM, FPGA or PLC. Centralized weighing buckets are equipped with limit switches and weight sensors. Among them, the limit switch includes two positions of open limit and close limit, which are connected to the control module through ordinary cables. Through the limit switch, signals such as open limit, indeterminate position (neither open limit nor close limit), close limit, etc. can be identified. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com