Dye automatic-mixing dual-baiance weighing apparatus

A technology of automatic batching and weighing device, applied in the direction of measuring device, weighing, special scale, etc., can solve the problems of trouble, lack of functions, reduce practical value, etc., to reduce the degree of participation, facilitate dust prevention, and ensure weighing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

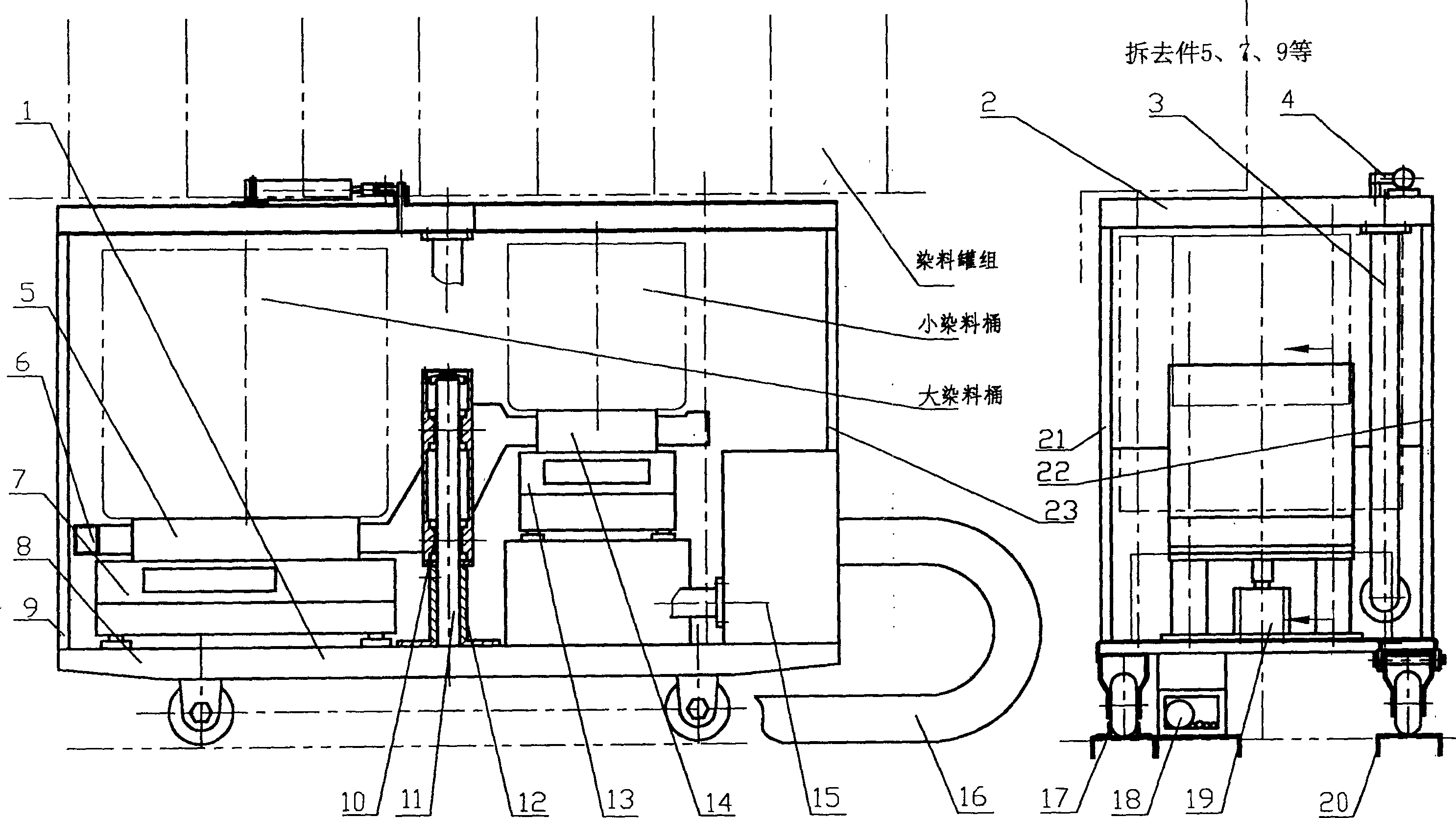

[0015] Example 1 see figure 1 , in a system, be equipped with a large range of common electronic scales 7 and a small range of high-precision electronic scales 13 each, installed on the same weighing car body 1. Respectively have a pallet on every scale, be pallet 5 on the scale 7, be pallet 14 on the scale 13. The elevating arm 6 that cylinder (or electric device) 19 drives is positioned at car body 1 middle part namely between two electronic scales 7,13, can be placed on it respectively one large and small dye bucket. The elevating arm 6 moves up and down along two parallel vertical shafts 11 through a sliding sleeve (or linear bearing) 10 . The two vertical shafts 11 are fixed on the bottom surface of the vehicle body 1 through the axle seats 12 . For preventing dust pollution, system has installed the vacuum cleaner 15 (equivalent to a common vacuum cleaner) that provides power supply by cable drag chain 16 on the car body, and is connected on the dust extraction hood 2 ...

Embodiment 2

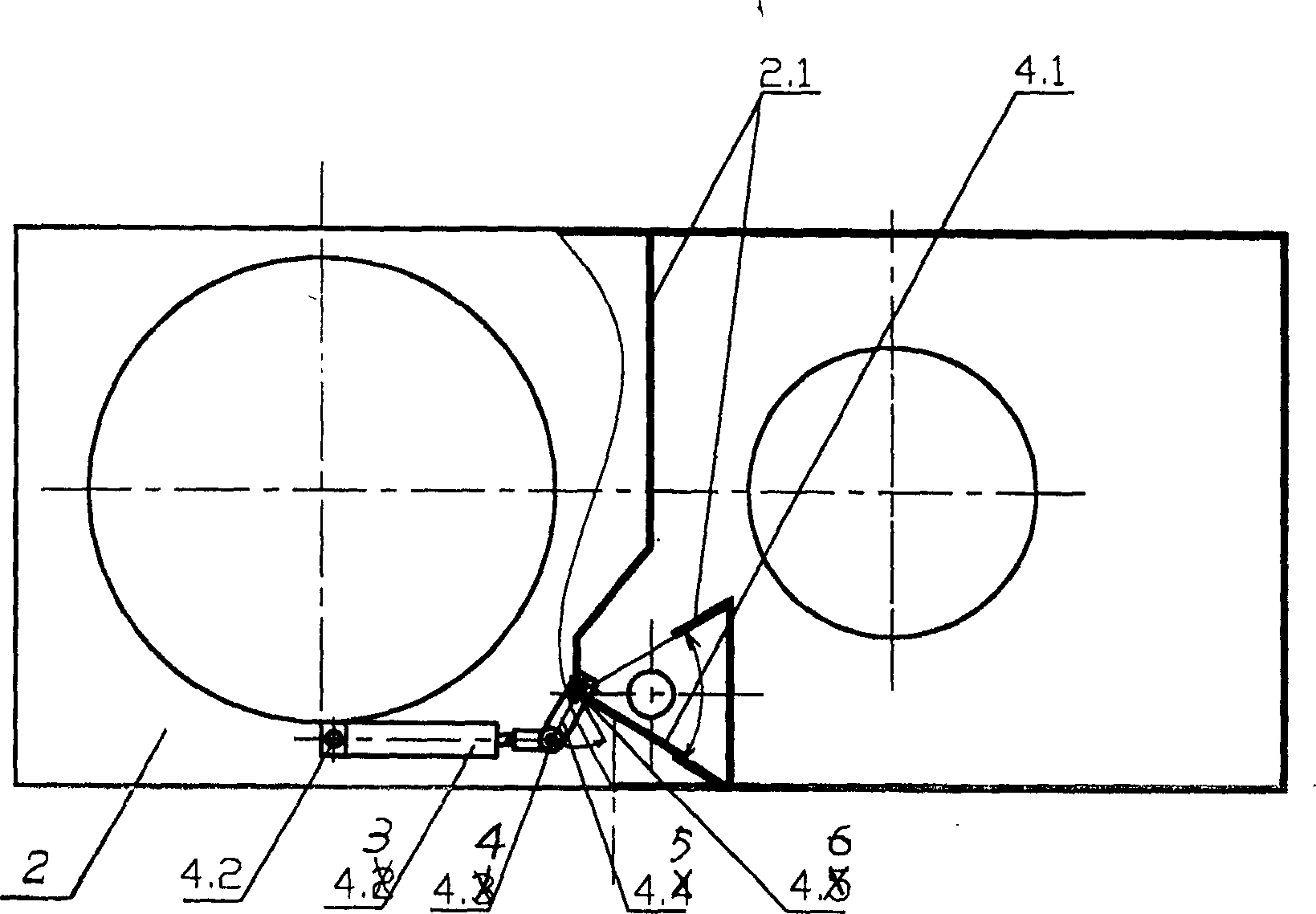

[0016] Embodiment 2 On the basis of Embodiment 1, the composition of the gas path conversion mechanism 4 is: see figure 2 , the cylinder 4.3 is installed on the dust extraction hood 2 through the pin shaft 4.2, and the rocker arm 4.5 on the rotating shaft 4.6 is driven by the cylinder 4.3 through the pin shaft 4.4 to swing, so that the rotating shaft 4.6 rotates the rotating plate installed at the entrance of the vacuum pipeline in the dust extraction hood 2 4.1, when the piston rod of the cylinder 4.3 is fully extended or fully retracted, the rotating plate 4.1 respectively leans against the partition plate 2.1 of one of the two air passages of the dust suction port to close the air passage of the dust suction port.

Embodiment 3

[0017] Embodiment 3 On the basis of Embodiment 1, the vacuum cleaner 15 installed on the vehicle body 1 of the system is only a dust collection box without a power device, and is connected to an external vacuum source through a cable drag chain 16 with a hose 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com