Pneumatic sealing control device at discharge port of screw conveyor

An auger conveyor and control device technology, which is applied to the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of material waste, heavy cleaning and cleaning workload, and uncompact equipment, to prevent Waste and environmental pollution problems, ensuring packaging measurement accuracy, ensuring the effect of weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

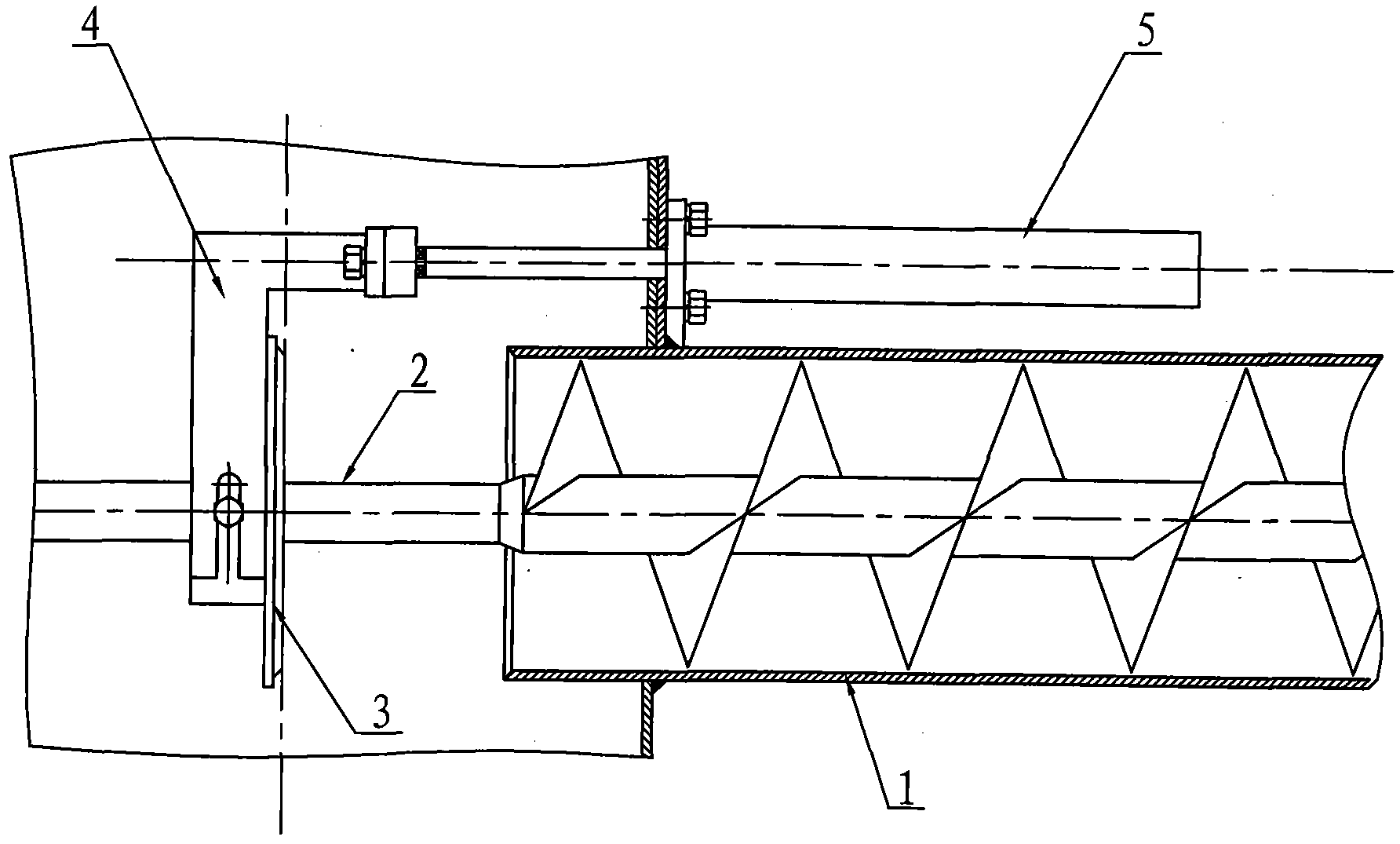

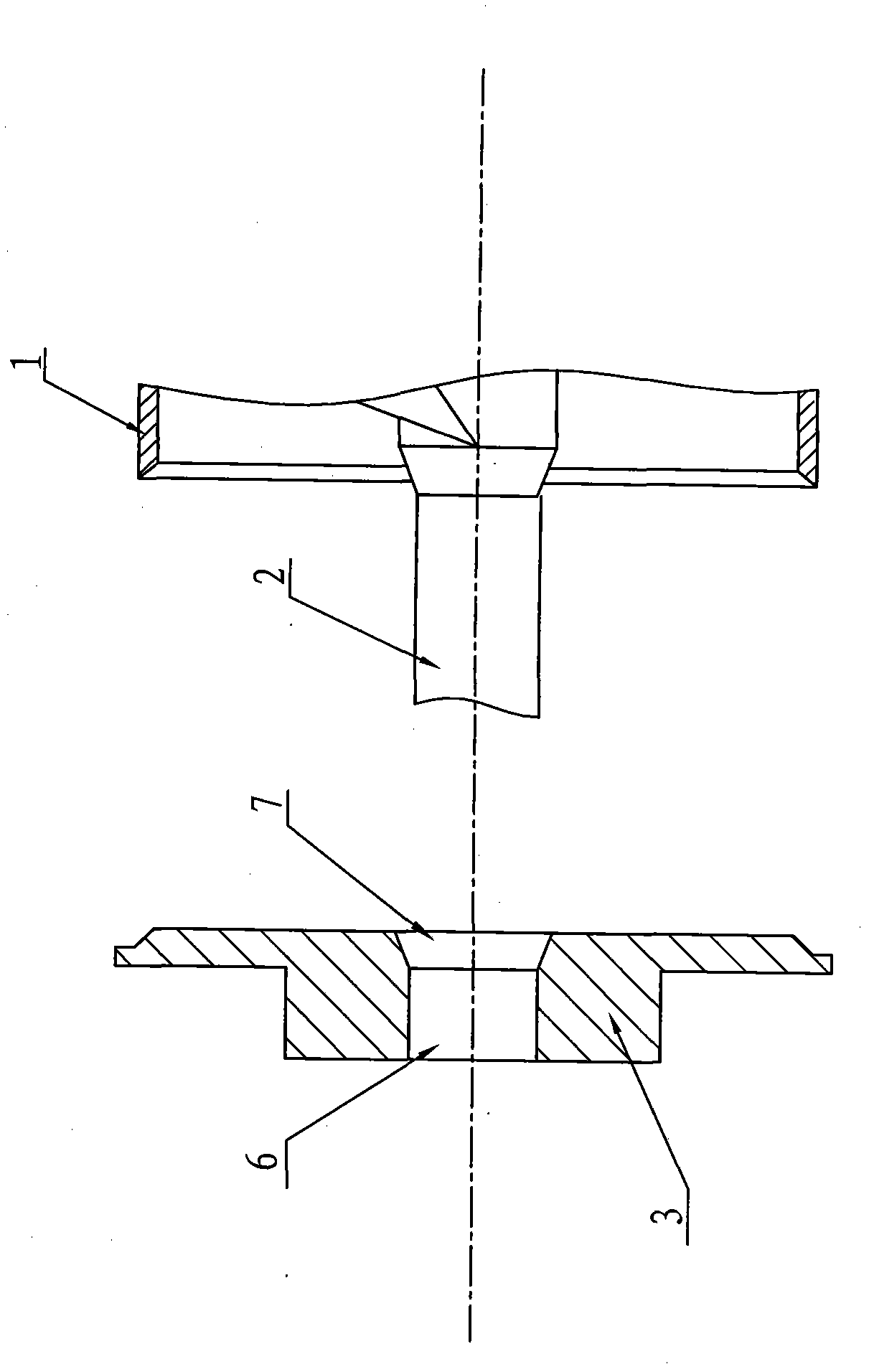

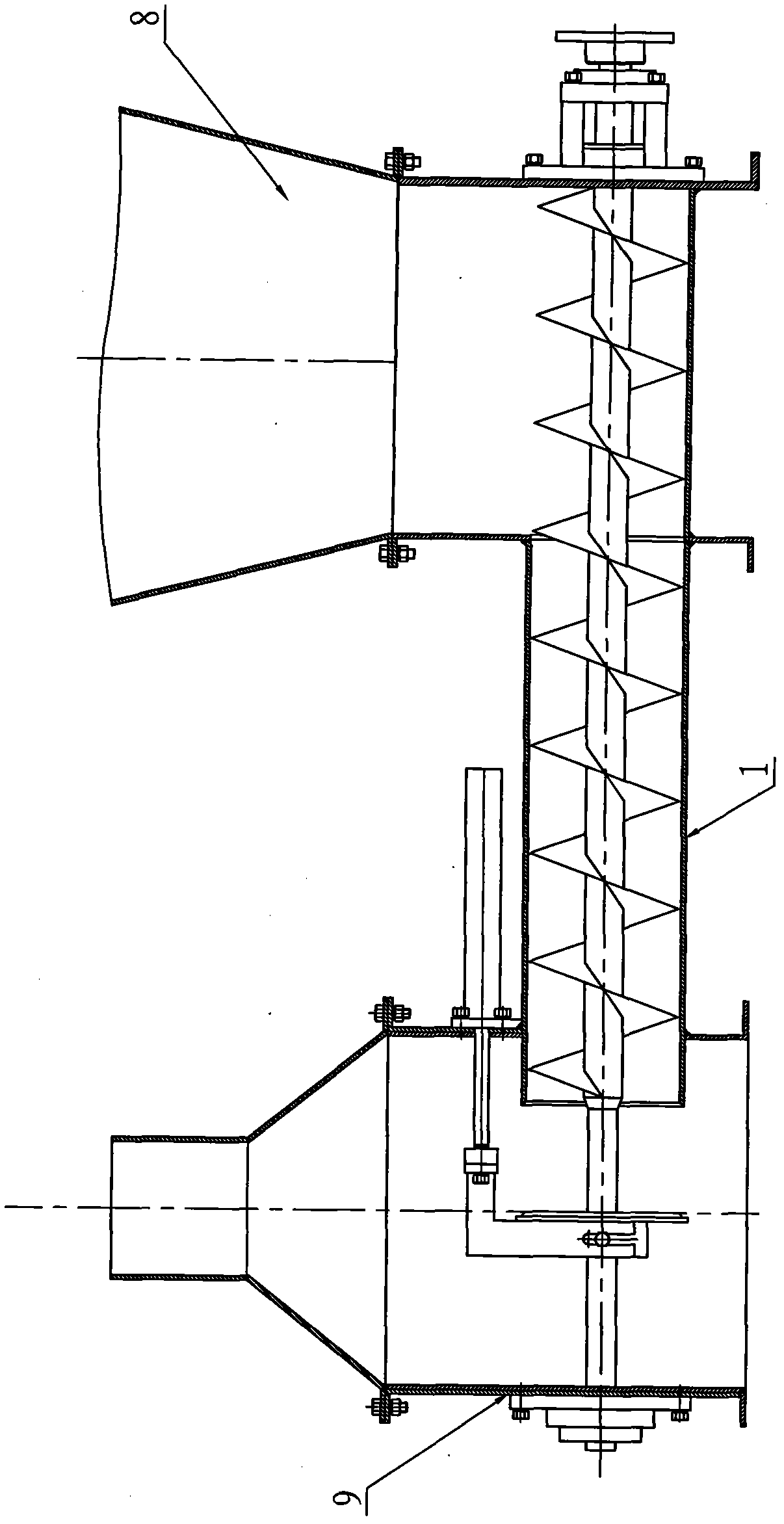

[0014] attached Figure 1 ~ Figure 3 It is a schematic diagram of the structure arranged between the feed hopper 8 and the discharge hopper 9 in the present invention, the pneumatic sealing control device of the discharge port of the auger conveyor includes the auger conveying pipe 1, the auger shaft 2, the plugging Cover 3, connecting seat 4 and cylinder 5, the plugging cover 3 is fixed on the connecting seat 4, the cylinder 5 is a two-rod cylinder, the connecting seat 4 is fixedly connected with two synchronous piston rods of the cylinder 5, and the plugging cover 3 A shaft hole 6 is provided in the center of the shaft hole 6, and an axial sealing surface 7 is provided on the outside of the shaft hole 6. The axial sealing surface 7 is a tapered sealing surface. The plugging cover 3 is set on the auger shaft 2 through the shaft hole 6. The plugging cover 3 is controlled by the cylinder 5. When the auger conveyor is in the state of stopping discharging, the cylinder 5 is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com