Bottle cap-type pulling suction nozzle cap with cuts

A nozzle cap and bottle cap type technology, which is applied to the field of bottle cap type removable scribed nozzle caps, can solve the problems of inconvenient movement and carrying, easily contaminated beverages, single opening, etc., and achieves good sealing, The effect of easy transportation and storage, not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

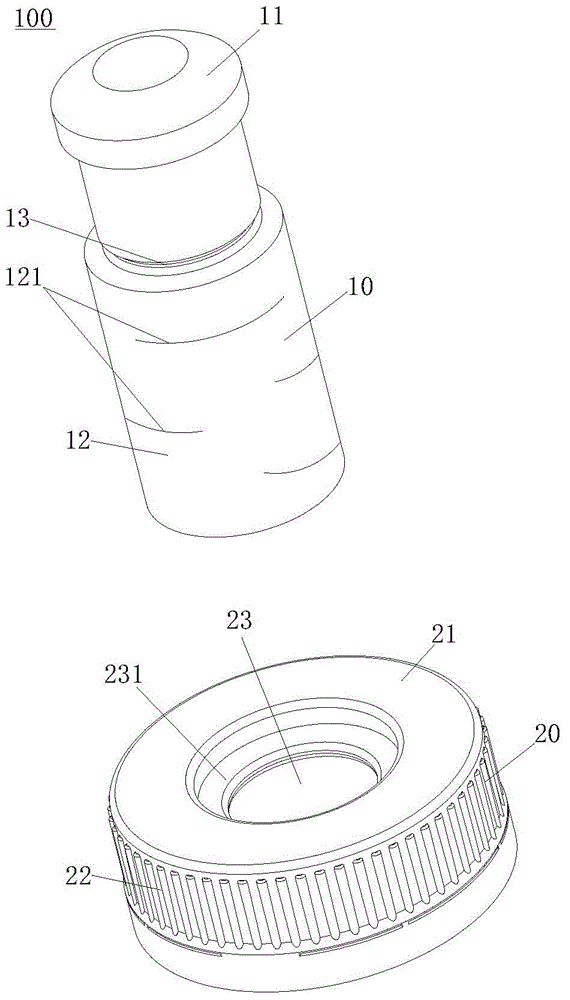

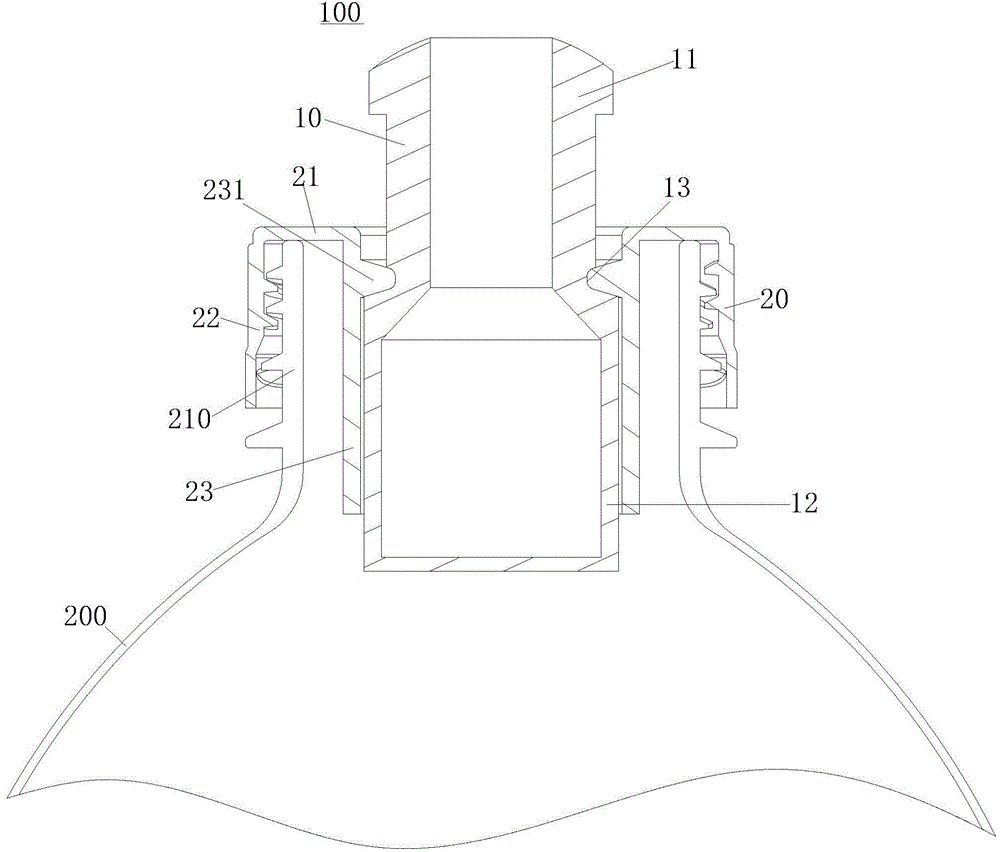

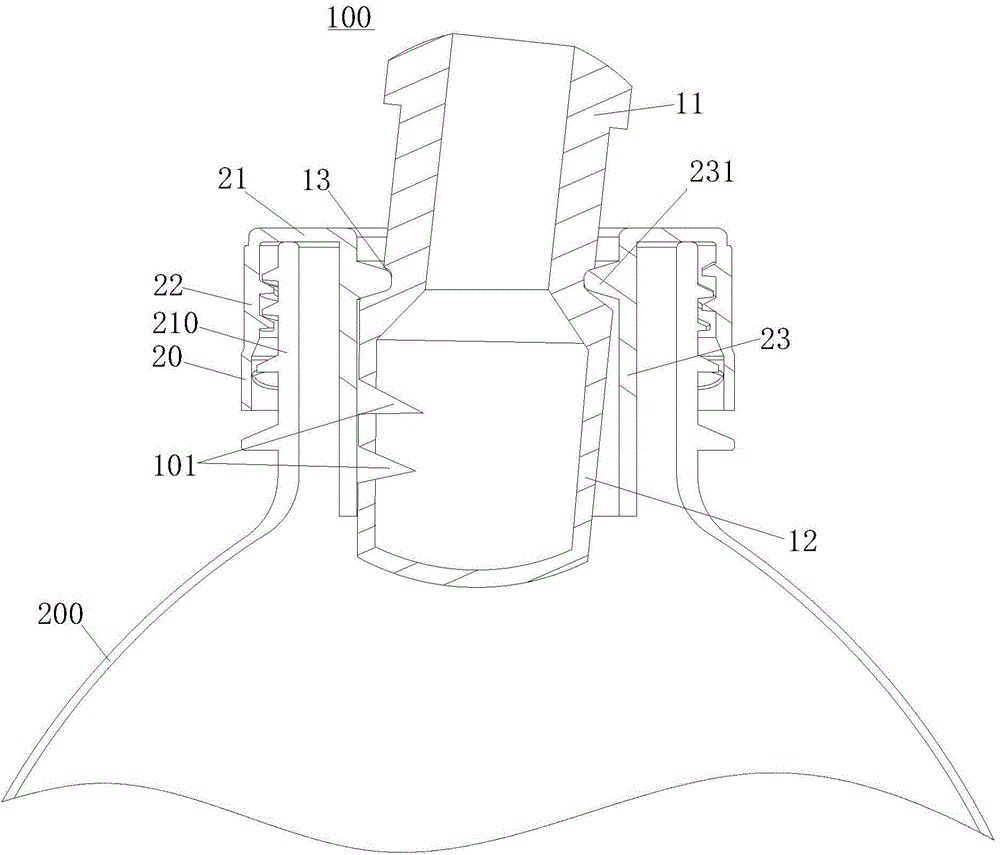

[0011] refer to Figure 1 to Figure 3 According to the present invention, the bottle cap-type movable nozzle cover 100 includes a suction nozzle 10 and a bottle cap 20 made of elastic materials.

[0012] The bottle cap 20 includes a top cover 21 and a side cover 22 integrally connected to the bottom edge of the top cover 21 . The middle part of the top cover 21 is recessed and protruded downwards to form a nozzle insert 23 . The upper end of the inner side wall of the nozzle inserting sleeve 23 protrudes inwards with a locking position 231 .

[0013] The suction nozzle 10 includes a suction nozzle head 11 and a sealing post 12 sequentially connected from top to bottom. The diameter of the sealing pillar is smaller than the inner diameter of the nozzle insert 23 , and the diameter of the nozzle head 11 is smaller than the diameter of the sealing pillar 12 . The junction of the nozzle head 11 and the sealing post 12 is recessed to form a locking groove 13 . The sealing post ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com