A wind-coal blowing furnace and a method for smelting brittle sulfur-lead-antimony ore using the wind-coal blowing furnace

A brittle sulfur-lead-antimony ore and air-coal blowing furnace technology is applied in the field of non-ferrous metal metallurgy, which can solve the problems of difficult separation of lead and antimony, environmental pollution, and difficulty in meeting national standards, and achieves improved metal recovery rate, reduced metal content, and saved energy. The effect of comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

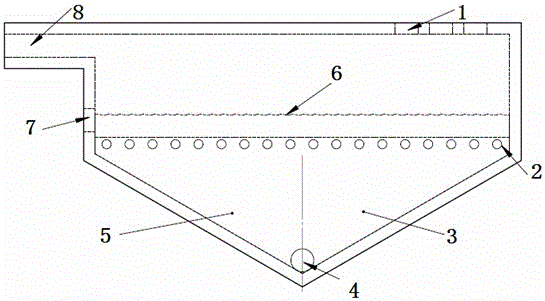

[0021] like figure 1 As shown, the air-coal blowing furnace includes a furnace body, a feed inlet 1, an air-coal inlet 2, an alloy outlet 4, a slag outlet 7 and a smoke outlet 8, the furnace body is a cylinder, and the bottom of the furnace body is conical. The furnace shaft is divided into a smelting zone 3 and a slag-depleted zone 5. The top of the furnace body corresponding to the smelting zone 3 is provided with a feed inlet 1, and the side of the furnace body corresponding to the slag-depleted zone 5 is provided with a smoke outlet 8. An alloy outlet 4 is provided at the mouth of the shaped bottom, and the slag in the furnace body forms a slag line 6, and a slag port 7 is provided on the side of the furnace body near the horizontal line of the slag line 6 and on the same side as the smoke outlet 8, and the slag port 7 is connected to the alloy outlet 4. The air coal port 2 is symmetrically arranged between the front and rear sides of the furnace body.

[0022] like im...

Embodiment 2

[0026] like figure 1 As shown, the air-coal blowing furnace includes a furnace body, a feed inlet 1, an air-coal inlet 2, an alloy outlet 4, a slag outlet 7 and a smoke outlet 8, the furnace body is a cylinder, and the bottom of the furnace body is conical. The furnace shaft is divided into a smelting zone 3 and a slag-depleted zone 5. The top of the furnace body corresponding to the smelting zone 3 is provided with a feed inlet 1, and the side of the furnace body corresponding to the slag-depleted zone 5 is provided with a smoke outlet 8. The mouth of the shaped bottom is provided with an alloy outlet 4, and the slag in the furnace body forms a slag line 6, and the side of the furnace body near the horizontal line of the slag line 6 and on the same side as the smoke outlet 8 is provided with a slag port 7, and the slag port 7 and the alloy outlet 4 The air coal port 2 is symmetrically arranged between the front and rear sides of the furnace body.

[0027] like image 3 Sho...

Embodiment 3

[0031] like figure 1 As shown, the air-coal blowing furnace includes a furnace body, a feed inlet 1, an air-coal inlet 2, an alloy outlet 4, a slag outlet 7 and a smoke outlet 8, the furnace body is a cylinder, and the bottom of the furnace body is conical. The furnace shaft is divided into a smelting zone 3 and a slag-depleted zone 5. The top of the furnace body corresponding to the smelting zone 3 is provided with a feed inlet 1, and the side of the furnace body corresponding to the slag-depleted zone 5 is provided with a smoke outlet 8. An alloy outlet 4 is provided at the mouth of the shaped bottom, and the slag in the furnace body forms a slag line 6, and a slag port 7 is provided on the side of the furnace body near the horizontal line of the slag line 6 and on the same side as the smoke outlet 8, and the slag port 7 is connected to the alloy outlet 4. The air coal port 2 is symmetrically arranged between the front and rear sides of the furnace body.

[0032] like im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com