Full-quantification and high-value utilization method of electric furnace fly ash and iron extraction tailings thereof

A technology of iron tailings and electric furnaces, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of low added value of products, long lead process, and many unorganized emissions, so as to reduce the cost of environmental governance, The effect of short smelting process and reduction of process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the present invention, a fully quantified and high-value utilization method of electric furnace dust and iron extraction tailings according to the present invention will be further described in detail in conjunction with the accompanying drawings and examples.

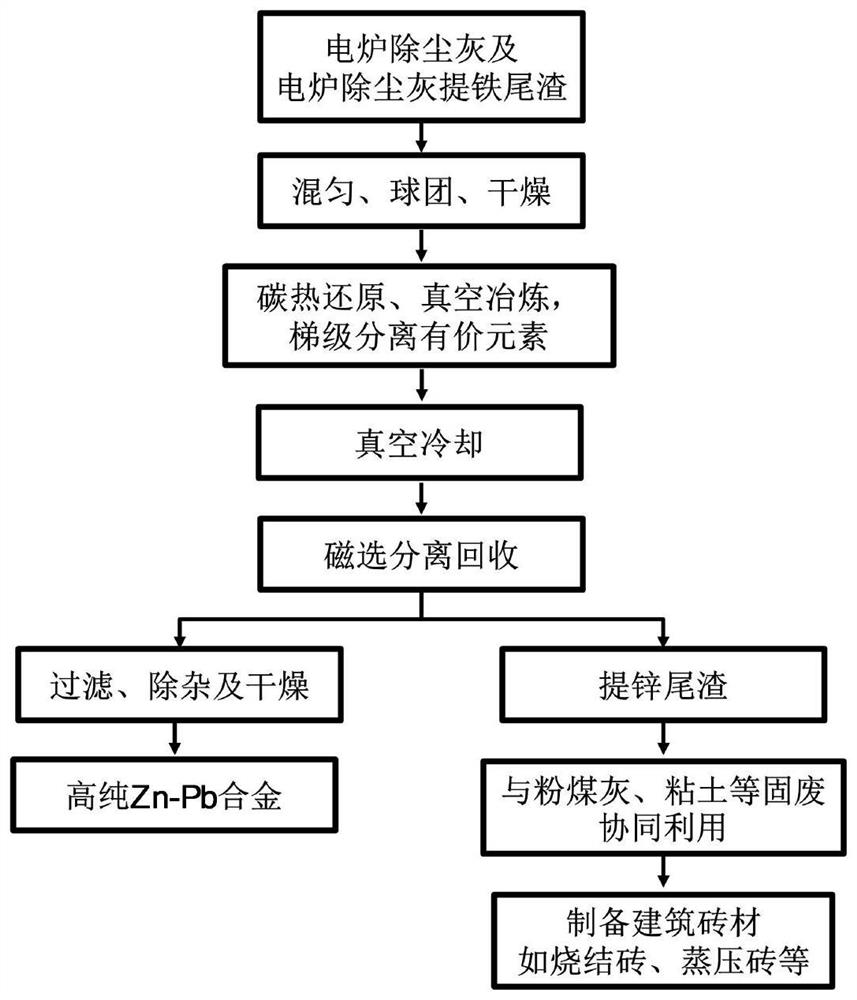

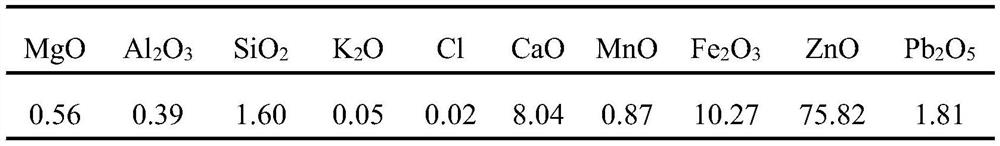

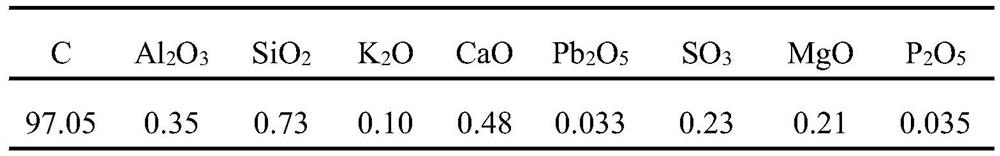

[0027]The present invention is a fully quantified and high-value utilization method of electric furnace dedusting ash and its iron-extracting tailings, which adopts carbothermal reduction, supplemented by vacuum smelting electric furnace dedusting ash to extract iron tailings, prepares Zn-Pb alloy, and uses the tailings to prepare sintering brick. Table 1 shows the XRF analysis results of the main components of the iron tailings extracted from the dust removal ash of the electric furnace. As can be seen from Table 1, the main components in the tailings are zinc-containing compounds; the purity of the graphite powder used is 97.35%, the average particle size is 0.045mm, and the main component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com