Air brick with high blowing through rate and manufacturing method thereof

A technology of high blow-through rate and air-permeable bricks, applied in the field of refractory materials, can solve the problems of difficult and uniform distribution of micro-pores, difficult distribution of micro-pore-forming agents, and reduced material strength, and achieves good ventilation effect and excellent volume stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

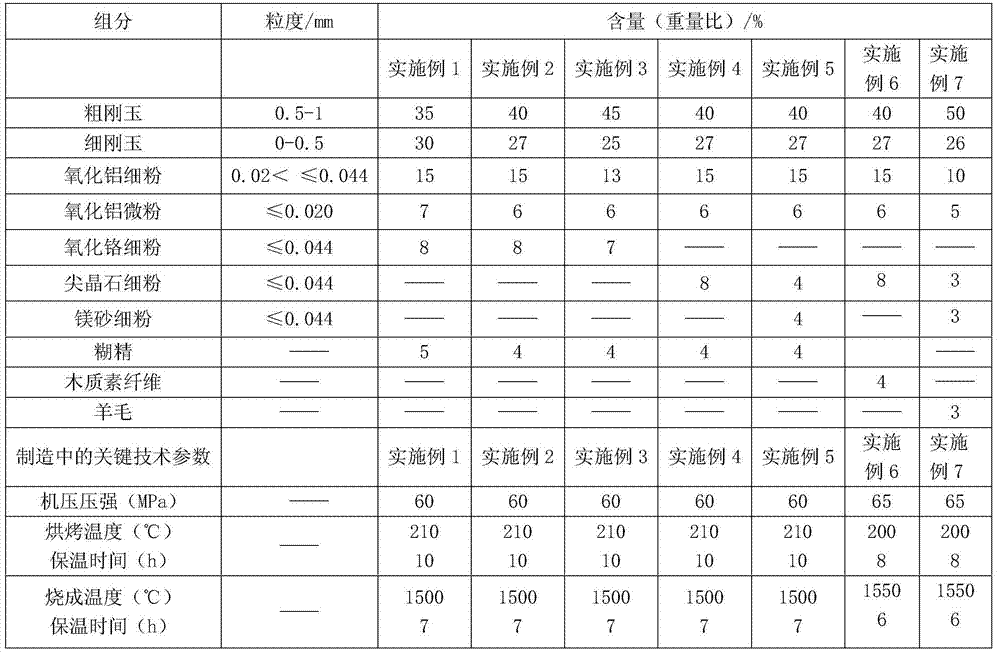

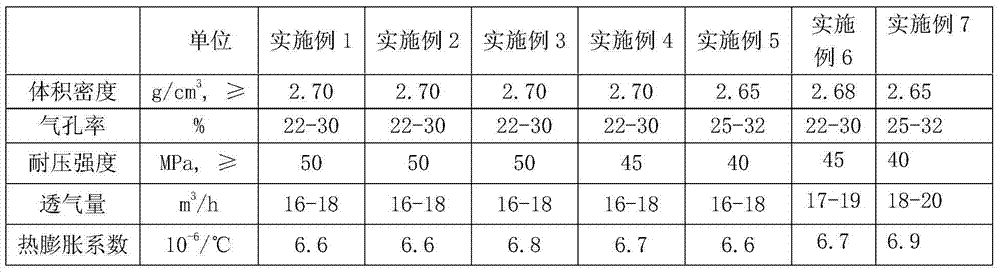

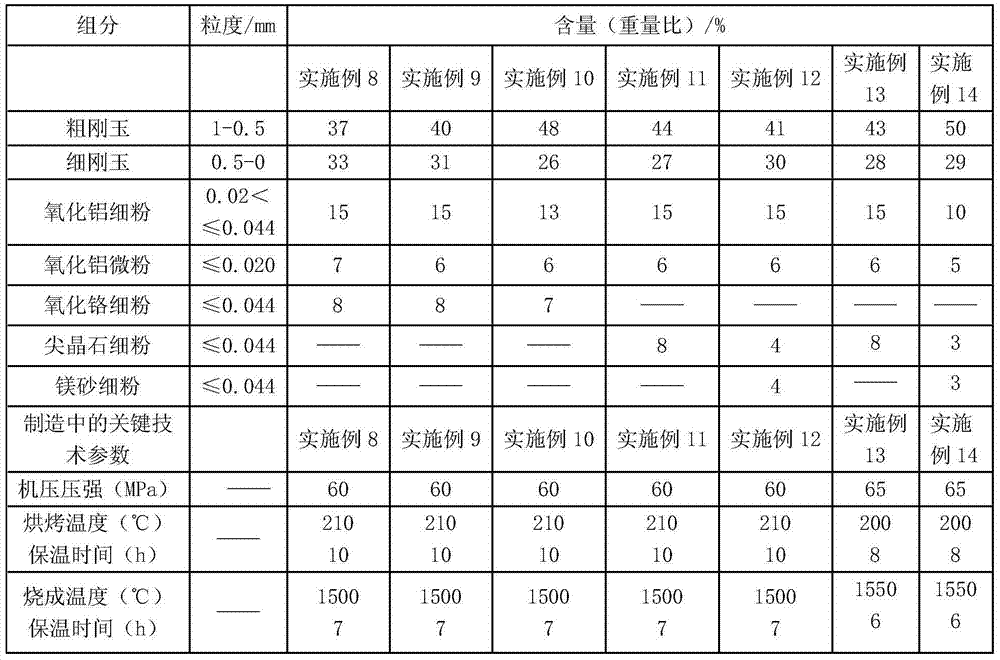

[0067] The first group of embodiments (see table 1):

[0068] Table 1

[0069]

[0070] The manufacture method of air-permeable brick in embodiment 1 to embodiment 7, comprises the following steps:

[0071] The first step: prepare raw materials according to the high blowing rate permeable brick formula (Al in the rough corundum or the fine corundum in embodiment 1-embodiment 7 2 o 3 ≥95wt%, the rough corundum and the fine corundum are both tabular corundum, and in other embodiments can also be one or more of dense corundum, white corundum and brown corundum), and the raw materials are processed according to the national standard test;

[0072] The second step: batching and mixing process;

[0073] The third step: trapped material process;

[0074] The fourth step: mold assembly process;

[0075] The fifth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com