Fire resistant viscose fiber and preparation method thereof

A flame retardant viscose fiber and viscose technology, which is applied in the textile field, can solve the problems of poor alkali resistance and many loss of flame retardant components after washing, and achieve the effects of saving materials, good flame retardant performance and controllable preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

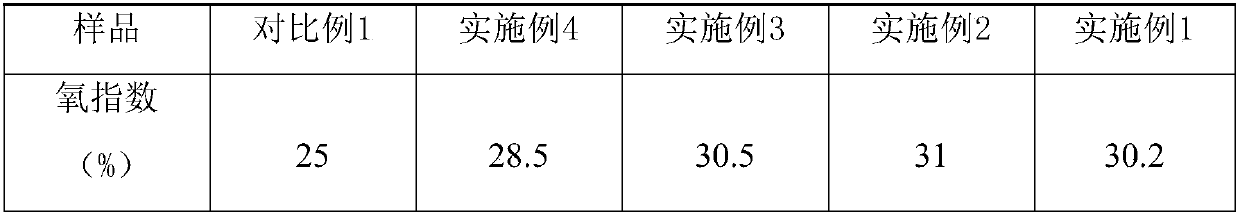

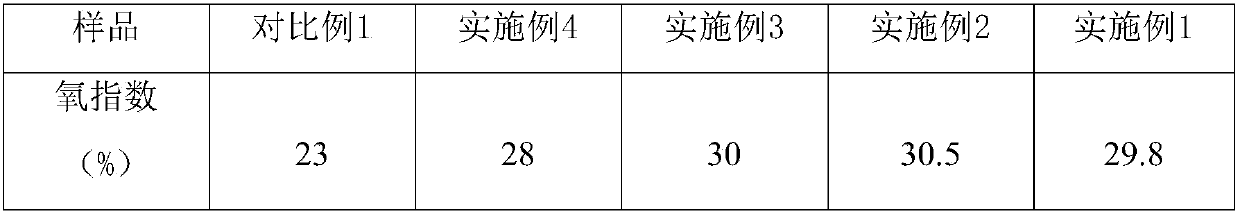

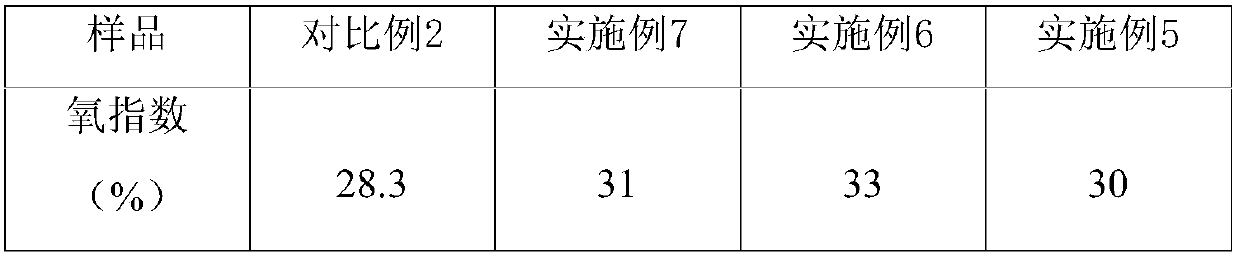

Embodiment 1

[0037] Bamboo pulp is used as raw material, and alkali cellulose is obtained through impregnation, pressing, crushing, aging and other process steps. Alkali cellulose contains 17.5% of alkali and 33.5% of α-cellulose (methyl cellulose);

[0038] Add the sodium silicate aqueous solution with a silicon dioxide concentration of 10% to the cellulose sodium sulfonate after the alkali cellulose has been yellowed, mix and dissolve it with the cellulose sodium sulfonate to form a flame-retardant cellulose viscose, and the addition of sodium silicate SiO 2 It is calculated as 25% of the weight of methyl fiber in the viscose solution, and after the steps of filtration, ripening, defoaming, and filtration, it is spun in a spinning bath. In the spinning bath, 110g / l of sulfuric acid, 8g / l of zinc sulfate, and 8g / l of sodium sulfate 320g / l, aluminum sulfate 10g / l, temperature 45°C, plasticized drawing, cutting, washing, desulfurization with sodium sulfite desulfurizer, oiling, drying to pr...

Embodiment 2

[0040] Using cotton pulp as raw material, alkali cellulose is obtained through impregnation, pressing, crushing, aging and other process steps. Alkali cellulose contains 17.5% of alkali and 33.0% of α-cellulose (methyl cellulose);

[0041] Add the sodium silicate aqueous solution with a silicon dioxide concentration of 13% to the sodium cellulose sulfonate after alkali cellulose yellowing, mix and dissolve it with sodium cellulose sulfonate to form a flame-retardant cellulose viscose, and the addition of sodium silicate SiO 2 It is calculated as 27% of the weight of methyl fiber in the viscose solution. After filtering, aging, degassing and filtering steps, it is spun in a spinning bath. In the spinning bath, 120g / l of sulfuric acid, 8g / l of zinc sulfate, and 8g / l of sodium sulfate 320g / l, aluminum sulfate 16g / l, temperature 43°C, plasticized drawing, cutting, washing, desulfurization with sodium sulfite desulfurizer, oiling, drying to prepare 2.22dtex×51mm flame retardant vis...

Embodiment 3

[0043] Bamboo pulp is used as raw material, and alkali cellulose is obtained through impregnation, pressing, crushing, aging and other process steps. Alkali cellulose contains 17.5% of alkali and 33.0% of α-cellulose (methyl cellulose);

[0044] Add an aqueous solution of sodium silicate with a silicon dioxide concentration of 15% to the spinning glue after the steps of filtration, aging, defoaming, and filtration using a syringe pump. The amount of sodium silicate is calculated as SiO 2 Calculated as 25% of the weight of methyl fiber in the viscose solution, spinning in the spinning bath, the sulfuric acid in the spinning bath is 122g / l, the zinc sulfate is 10g / l, the sodium sulfate is 325g / l, and the aluminum sulfate is 20g / l , the temperature is 45°C, and then plasticized and drawn, cut, washed, desulfurized with sodium sulfite desulfurizer, oiled and dried to prepare 3.33dtex×64mm flame-retardant viscose fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com