Preparation method of aluminum-doped material of cathode of lithium ion battery with solid phase process

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low bulk density of powder materials, poor high-temperature safety performance and high-temperature cycle performance, and difficulty in mixing materials uniformly. To achieve the effect of simple and easy operation of the process, good controllability of product quality, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

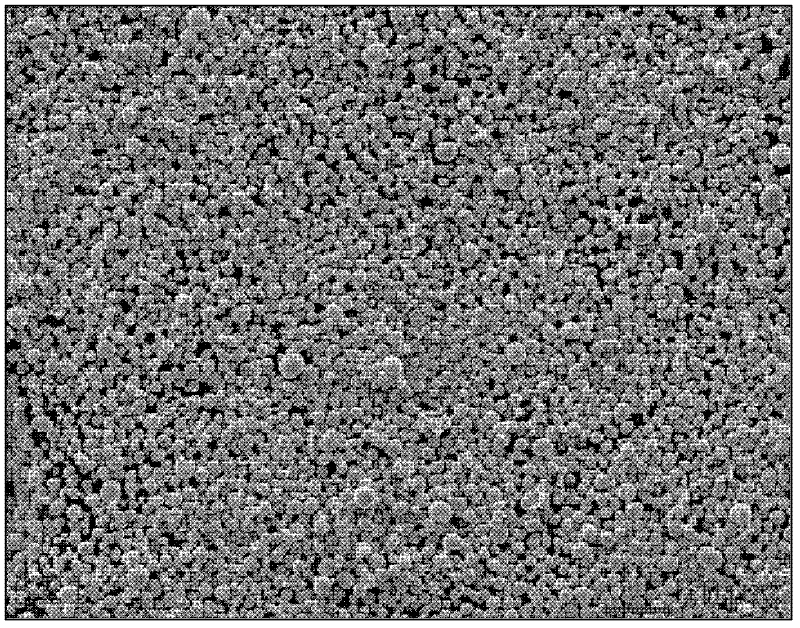

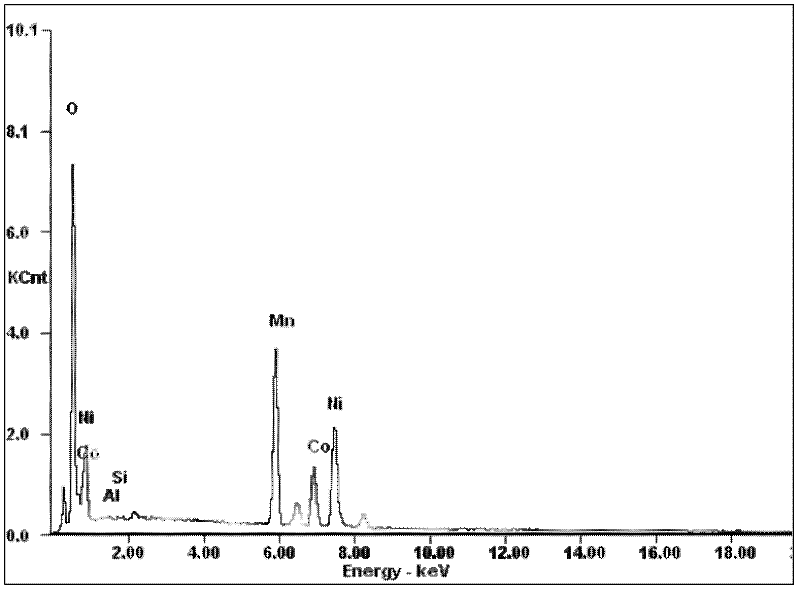

[0027] NiSO 4 、CoSO 4 , MnSO 4 Moore than Ni 2+ :CO 2+ :Mn 2+ =4: 2: 4 ratio mixing, dissolving with deionized water, is made into the solution that comprehensive ion concentration is 2mol / L. Prepare 4mol / L sodium hydroxide solution, and add NH in the sodium hydroxide solution 3 ·H 2 O: NaOH=0.2 ammonia water. Add the two mixed solutions into the reaction kettle in parallel, under the protection of nitrogen or inert gas, control the reaction in a continuous reaction mode, the pH value is controlled between 10-12, the temperature is 50-60°C, filter and wash to the pH value of the washing water less than 8, dry at 120°C to get Ni 0.4 co 0.2 mn 0.4 (OH) 2 Precursor.

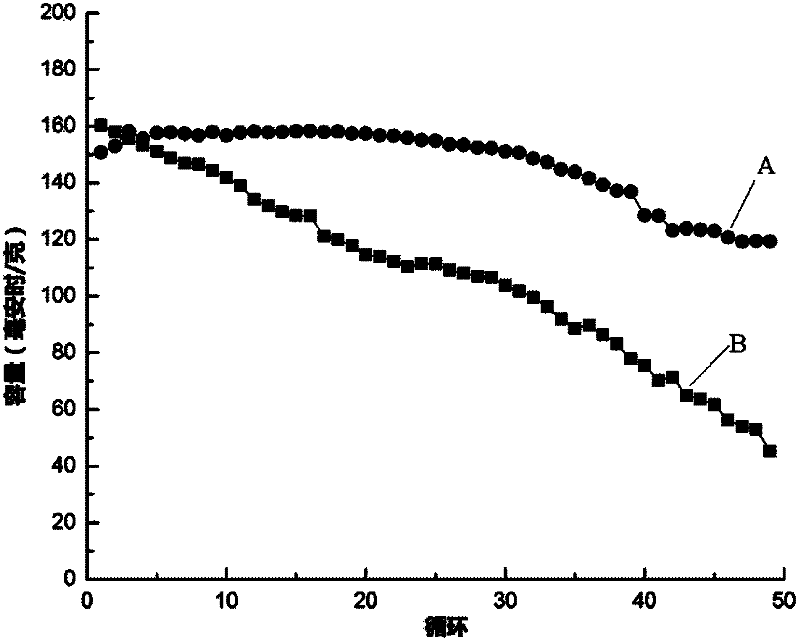

[0028] According to the molar ratio of Al / (Ni+Mn+Co)=0.02, Li / (Ni+Co+Mn+Al)=1.05, weigh nano-scale aluminum isopropoxide, lithium carbonate and the prepared precursor, and mix them uniformly for 4 hours , Put the uniformly mixed material into a sintering furnace for sintering, in the air atmosphere, kee...

Embodiment 2

[0037] NiCl 2 、CoCl 2 , MnCl 2 Moore than Ni 2+ :CO 2+ :Mn 2+ =70:15:15 ratio mixing, dissolving with deionized water, is made into the solution that comprehensive ion concentration is 2mol / L. Prepare 4mol / L sodium hydroxide solution, and add NH in the sodium hydroxide solution 3 ·H 2 O: NaOH=0.2 ammonia water. Put the two mixed solutions into the reaction kettle in parallel, under the protection of nitrogen or inert gas, control the reaction in a continuous reaction mode, the pH value is controlled between 10-12, the temperature is 50-60 ° C, filter and wash to the pH value of the washing water less than 8, dry at 120°C to get Ni 0.7 co 0.15 mn 0.15(OH) 2 Precursor.

[0038] According to the molar ratio of Al / (Ni+Mn+Co)=0.02, Li / (Ni+Co+Mn+Al)=1.15, weigh nano-scale aluminum isopropoxide, lithium carbonate and the prepared precursor, and mix them uniformly for 4 hours , Put the uniformly mixed materials into a sintering furnace for sintering, in an oxygen atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com