A method for hot-dip aluminum plating of steel structure parts

A technology for hot-dip aluminum and steel structural parts, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of uncontrollable coating phase and particle precipitation and growth, and achieve the goal of overcoming hot-dip coating. Poor plating performance, prevention of aluminum pollution, and excellent immersion plating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

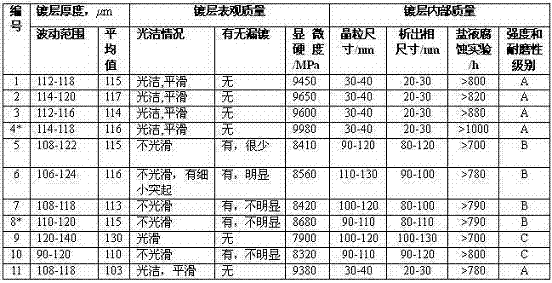

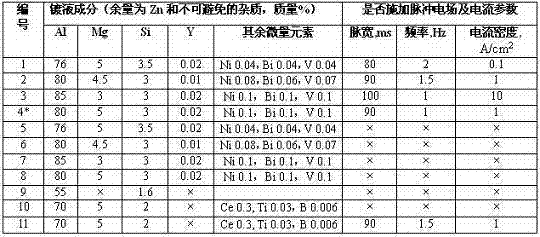

[0036] For verifying and adopting the effect of the present invention, the following series of hot-dip aluminizing comparative tests have been carried out to the steel structure of No. 20 steel materials:

[0037] Series 1: The present invention is fully adopted, that is, the hot-dip aluminum-coated multi-element alloy of the present invention is used at the same time and the method of applying a pulsed electric field during the hot-dip plating process is adopted; (Note: No. 1-4 in Table 1).

[0038] Series 2: Only the hot-dip aluminum-coated multi-component alloy of the present invention is used, and no pulse electric field is applied during the hot-dip plating process; (Note: No. 5-8 groups in Table 1).

[0039] Series 3: The existing hot-dip aluminum alloy, using Galvalume alloy; (Note: No. 9 group in Table 1).

[0040] Series 4: Select the existing technology (Chinese patent application number 200910044817.8) using Mg 2 Hot-dip plating tests were carried out on the alloys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com