Treatment method for purifying zinc pot in hot galvanizing production

A purification treatment and hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as excessive Fe content in zinc pot, slag belt defects, and zinc slag adhered to the surface of the strip steel , to achieve the effect of improving quality, improving purity, improving adhesion and gloss of zinc layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

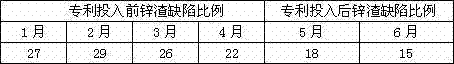

[0015] The purification treatment method of the zinc pot in the hot-dip galvanizing production is illustrated by taking the 2# galvanizing line of a cold rolling plant in Hebei as an example. Since the production line itself is not equipped with a cleaning section, the Fe content in the zinc pot often exceeds the standard, and the surface of the strip often A large amount of zinc slag is adhered, and in severe cases, slag belt defects are formed. Using this purification treatment method, the zinc pot purification treatment is carried out every other week (7 days). The specific operation process is as follows:

[0016] 1) Increase the aluminum content to 0.25-0.3%, and the staff on duty will increase the number of samples sent to 5-7 times to control the aluminum content in the zinc pot; maintain at least one shift production time (8-12h).

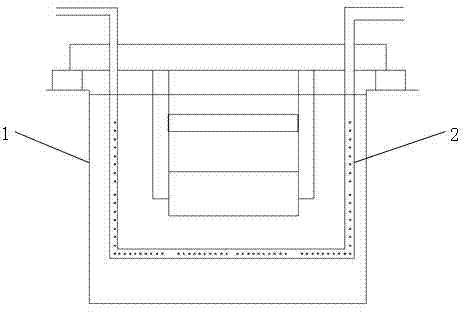

[0017] 2) figure 1 As shown, utilize the high-pressure nitrogen cylinder and the blowing pipeline 2 that is arranged in the zinc pot 1, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com