High temperature resistance protective coating and preparing method and application thereof

A protective coating and high temperature resistant technology, which is applied in the field of materials, can solve the problems of poor wear resistance and low hardness of titanium metal, and achieve the effects of improving bonding performance, improving friction and corrosion resistance, improving overall performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

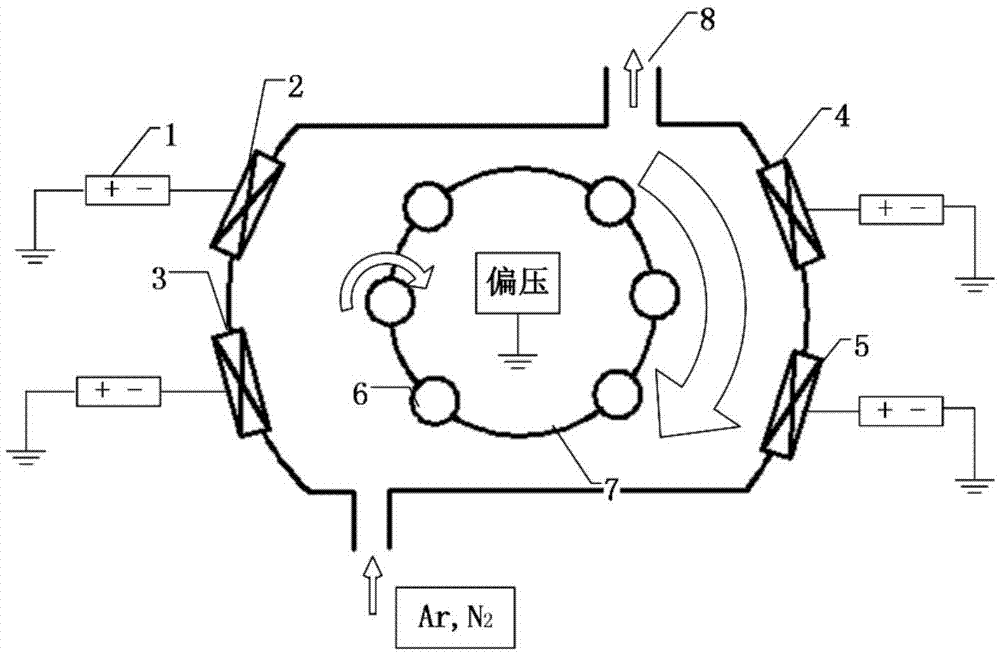

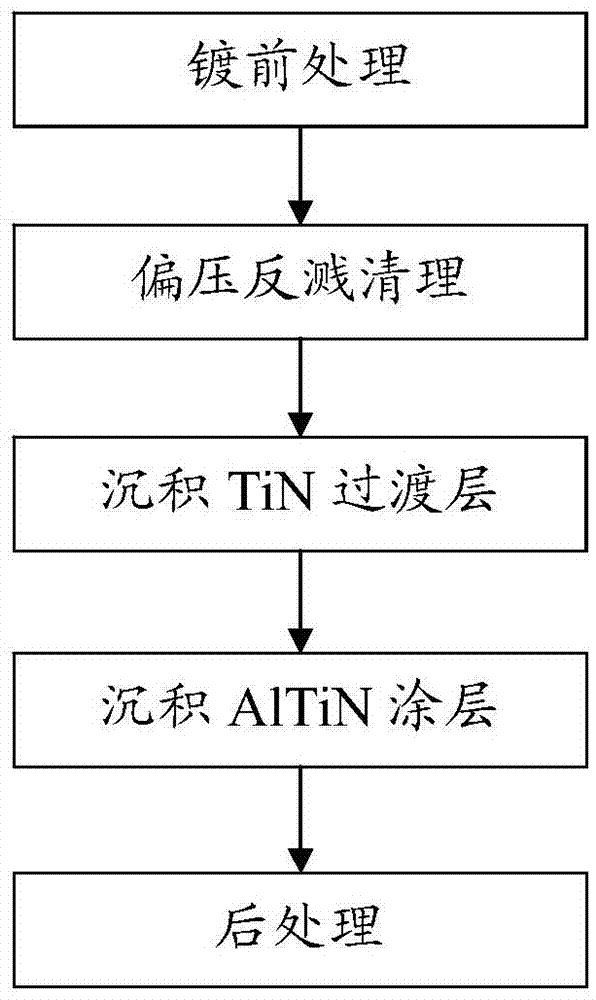

[0027] Another aspect of the embodiments of the present invention provides a method for preparing a high temperature resistant protective coating, comprising the steps of:

[0028] (1) The target material is Ti target, and the working atmosphere is N 2 , using arc ion plating technology to deposit a TiN transition layer on the surface of the substrate;

[0029] (2) Simultaneously use Al target and Al 67 Ti 33 The target is the target material, and the AlTiN coating is continuously deposited on the TiN transition layer by arc ion plating technology.

[0030] The preparation method uses the Ti target as the Ti source of the transition layer TiN, and adopts high-purity N 2 As a reaction gas, it is ionized and combined with Ti element to deposit a hard TiN transition layer on the substrate surface; using pure Al target and AlTi target as the source of Al and Ti elements for preparing AlTiN coating, by controlling the pure Al target and AlTi target respectively The current of t...

Embodiment 1

[0044] Example 1: please combine figure 2 As shown, the preparation method of the high temperature resistant protective coating of the present embodiment comprises the following specific steps:

[0045] (1) Pre-plating treatment

[0046] Put the high-speed cutting tool as the matrix into petroleum ether, and use ultrasonic agitation to clean it for 30 minutes. After removing the oil on the surface of the high-speed cutting tool, put it in acetone and ultrasonically clean it for 20 minutes, then ultrasonically clean it in absolute ethanol for 15 minutes, and finally take it out with Blow dry with nitrogen;

[0047] (2) Bias reverse sputter cleaning

[0048] Put the high-speed cutting tool after the above treatment into the chamber, heat the temperature of the reaction chamber to 400°C, and pre-evacuate the backside vacuum to 4.00×10 -3 Pa. Introduce high-purity Ar (purity ≥ 99.99%), flow rate 100sccm, turn on the DC power supply of Ti target (purity ≥ 99.9%), set the targe...

Embodiment 2

[0057] Embodiment 2: The substrate in the preparation method of the wear-resistant protective coating of this embodiment is the titanium alloy heat exchanger plate in the marine key parts, which includes the following specific steps:

[0058] (1) Utilize the method for embodiment 1 step 1 to implement pre-plating treatment to the titanium alloy heat exchanger plate;

[0059] (2) Utilize the method for embodiment 1 step 2 to implement bias reverse sputtering cleaning to the titanium alloy heat exchanger plate;

[0060] (3) Utilize the method for embodiment 1 step 3 to deposit hard TiN transition layer to titanium alloy heat exchanger plate;

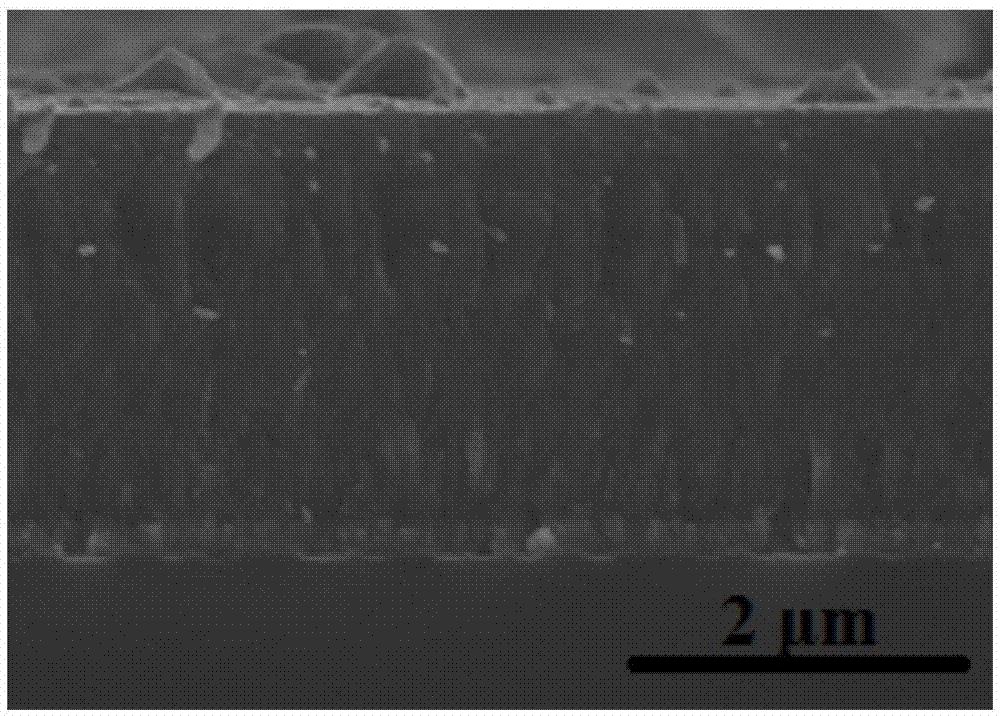

[0061] (4) An arc ion plating system is used to deposit an AlTiN coating on the surface of the TiN transition layer titanium alloy heat exchanger plate. The target material used is still a group of metal Al targets (purity ≥ 99.9%), and two groups of Al 67 Ti 33 Target, in the state of uninterrupted vacuum coating, the base vacuum of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com