AlMoCN gradient composite coating tool and preparing method thereof

A composite coating and cutting tool technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., to achieve the effect of high hardness and strength, low surface friction coefficient, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

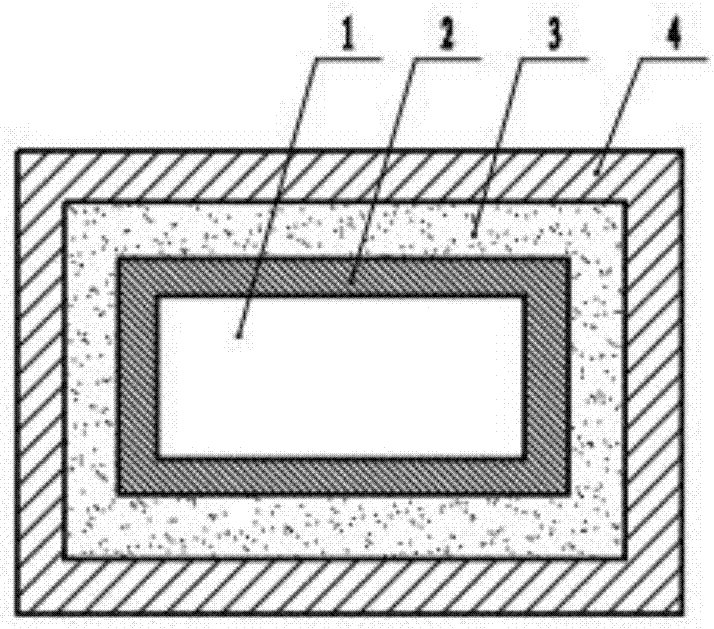

Image

Examples

Embodiment 1

[0023] The AlMoCN gradient composite coating tool and its preparation method of the present invention, the tool is a common milling blade, its base material is: cemented carbide M05, the deposition method is a composite coating method using unbalanced magnetron sputtering+arc plating, Two unbalanced magnetron sputtering AlMoC composite targets and two arc plating Ti targets were used for deposition. First, the Ti transition layer was deposited by arc plating, and then the AlMoC transition layer and the AlMoCN gradient composite coating with gradually changing nitrogen content were deposited by unbalanced magnetron sputtering. Specific steps are as follows:

[0024] (1) Pretreatment: Polish the surface of the tool base to remove impurities such as oil stains and rust on the surface, then place them in alcohol and acetone in turn, and ultrasonically clean them for 20 minutes each to remove oil stains and other attachments on the tool surface, and dry them with a hair dryer quick...

Embodiment 2

[0031] AlMoCN gradient composite coating cutter of the present invention and preparation method thereof, this cutter is common twist drill bit, and its cutter base material is: high-speed steel W18Cr4V, and deposition mode is the composite coating method that adopts unbalanced magnetron sputtering+arc plating, during deposition Two unbalanced magnetron sputtering AlMoC composite targets and two arc plating Ti targets were used. First, the Ti transition layer was deposited by arc plating, and then the AlMoC transition layer and the AlMoCN gradient composite coating with gradually changing nitrogen content were deposited by unbalanced magnetron sputtering. Its preparation method is:

[0032] (1) Pretreatment: Polish the surface of the tool base to remove impurities such as oil stains and rust on the surface, then place them in alcohol and acetone in turn, and ultrasonically clean them for 20 minutes each to remove oil stains and other attachments on the tool surface, and dry the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com