High-strength and high-temperature-resistant magnesium alloy

A technology of high temperature resistance and magnesium alloy, applied in the field of metal materials, it can solve the problems that magnesium alloys are far inferior to aluminum alloys, have poor heat resistance and corrosion resistance, and the oxide film on the electrode surface is not dense, so as to reduce the atomic diffusion rate. , the effect of improving heat resistance, room temperature strength and high temperature creep performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific technical solution of the present invention will be described in detail below through specific examples.

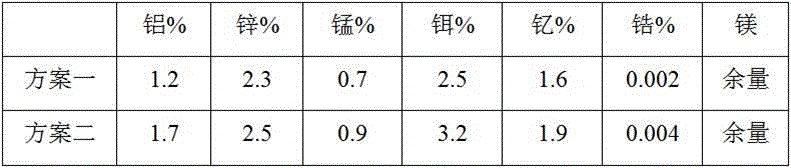

[0015] The invention is a high-strength and high-temperature resistant magnesium alloy, which mainly includes magnesium, aluminum, zinc, manganese, erbium, yttrium, zirconium and other elements, and its composition is as follows: aluminum 1-2%, zinc 2-3%, manganese 0.5% -1%, erbium 2-3.5%, yttrium 1.5-2%, zirconium 0.02-0.05%, silicon <0.02%, copper <0.002%, iron <0.002%, other impurities <0.005%, and magnesium as the balance.

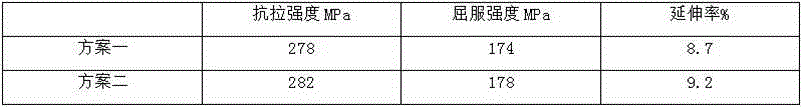

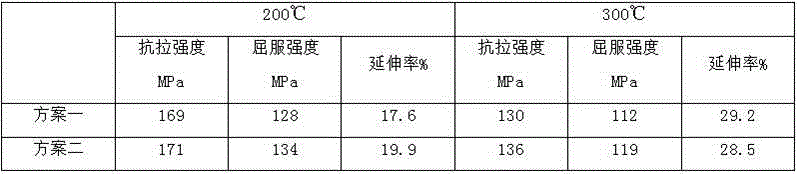

[0016] Two specific implementations such as figure 1 as shown, figure 2 Shown are the corresponding room temperature mechanical properties of the two schemes as, image 3 Shown are the corresponding high temperature mechanical properties of the two schemes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com