Method and device for manufacturing micro-fluidic chip with femtosecond plasma grating

A microfluidic chip and plasma technology, which is applied in the manufacture of microstructure devices, microstructure devices, manufacturing tools, etc., can solve the problems that are not conducive to femtosecond laser fine processing and reduce processing efficiency, so as to reduce production time and increase The effect of movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

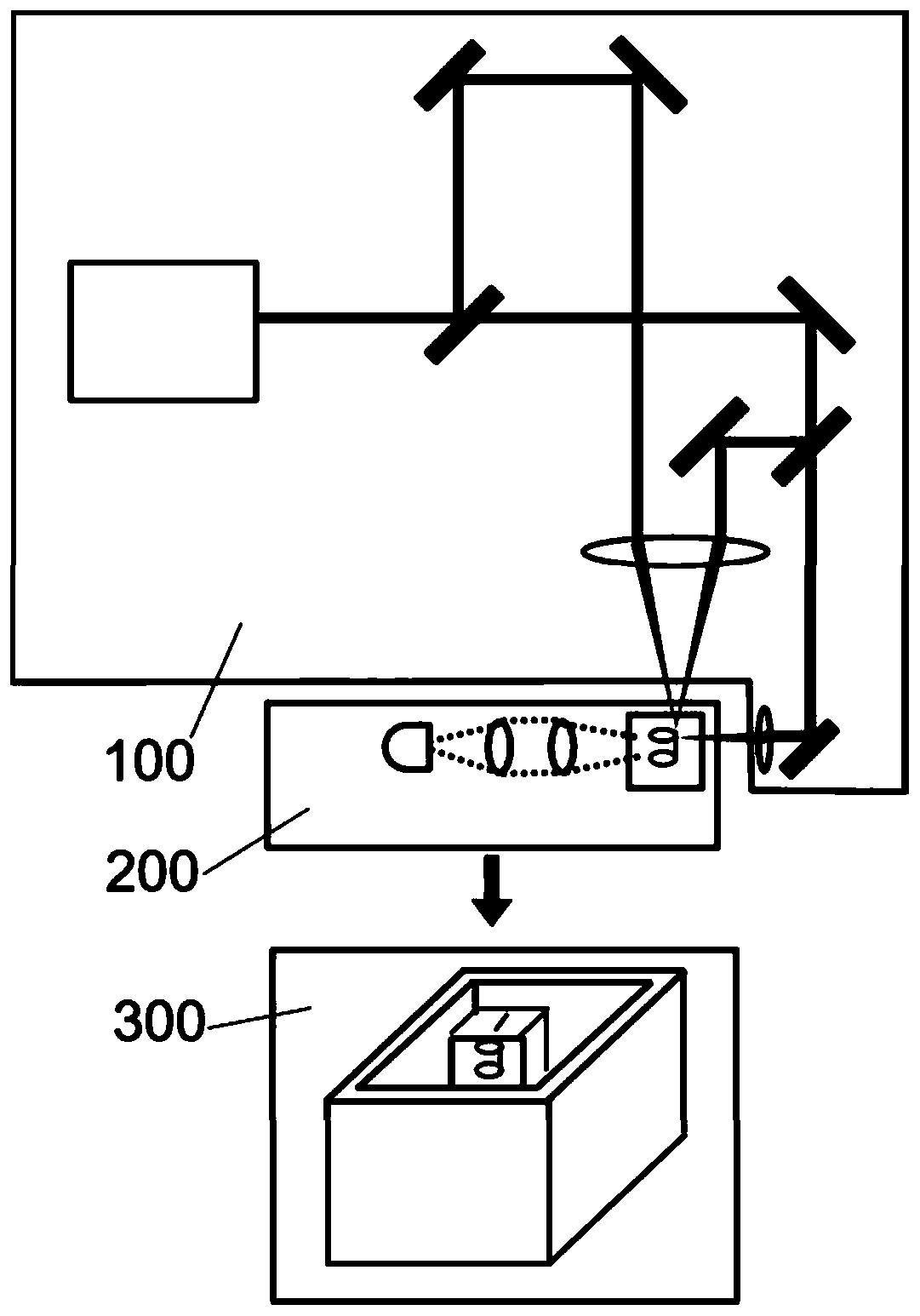

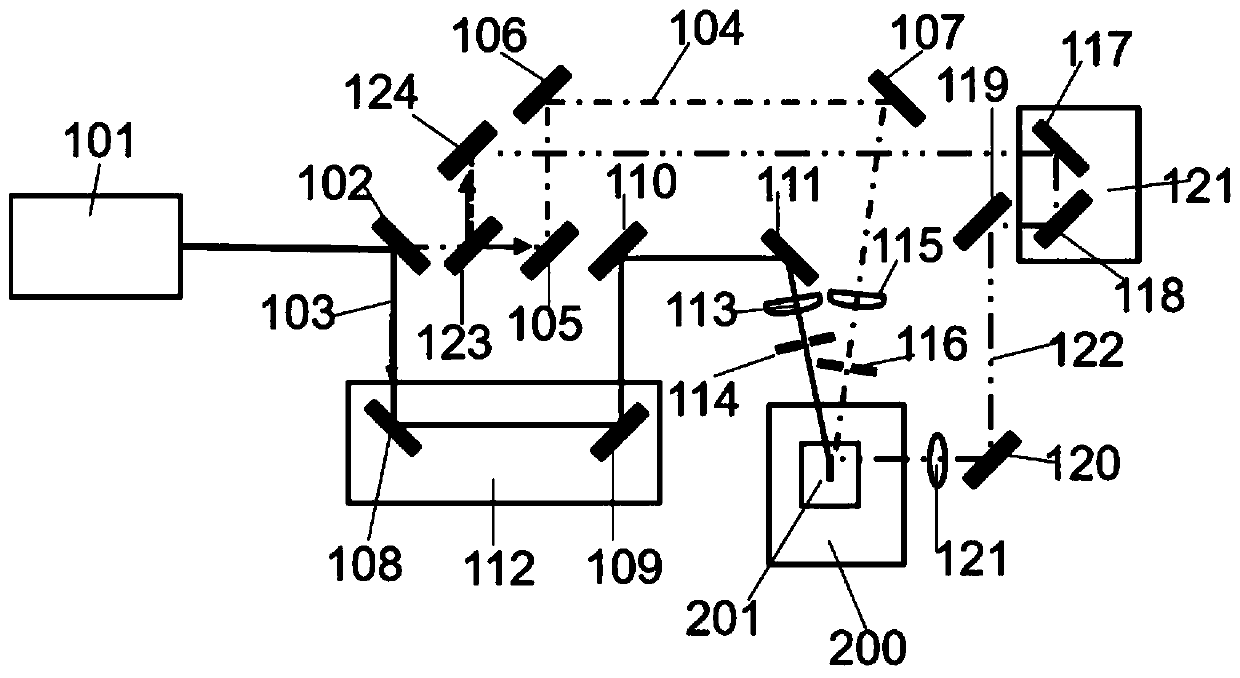

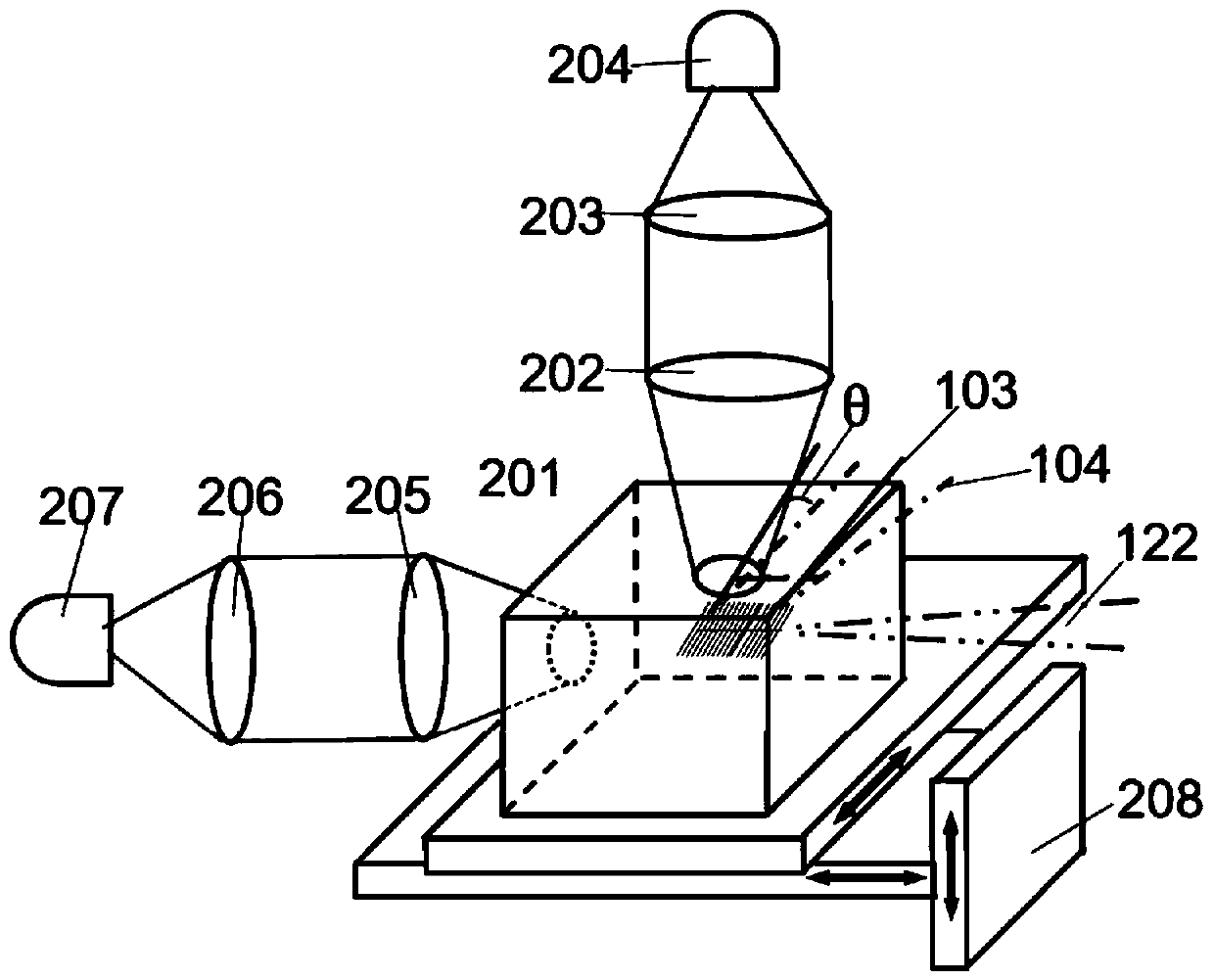

[0035] See attached figure 2 , the femtosecond pulsed laser output by the femtosecond pulsed laser 101 in the plasma grating optical path 100 is divided into after passing through the plane beam splitter 102 which reflects 30% and transmits 70% and the beam splitting ratio is one to one plane beam splitter 102. First reflected beam 103 at 30% power, second reflected beam 122 at 35% power and transmitted beam 104 at 35% power. The first time domain delay controller is made up of the 4th plane mirror 108, the 5th plane mirror 109 and displacement platform 112, and the second time domain delay controller is made up of the 9th plane mirror 117, the 10th plane mirror 118 and displacement The platform 121 is composed. The first reflected light beam 103 changes the optical path through the sixth plane mirror 110 and the seventh plane mirror 111 after passing through the first time domain delay controller, and converges after passing through the first plano-convex cylindrical lens 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com