Patents

Literature

39results about How to "Large lattice distortion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

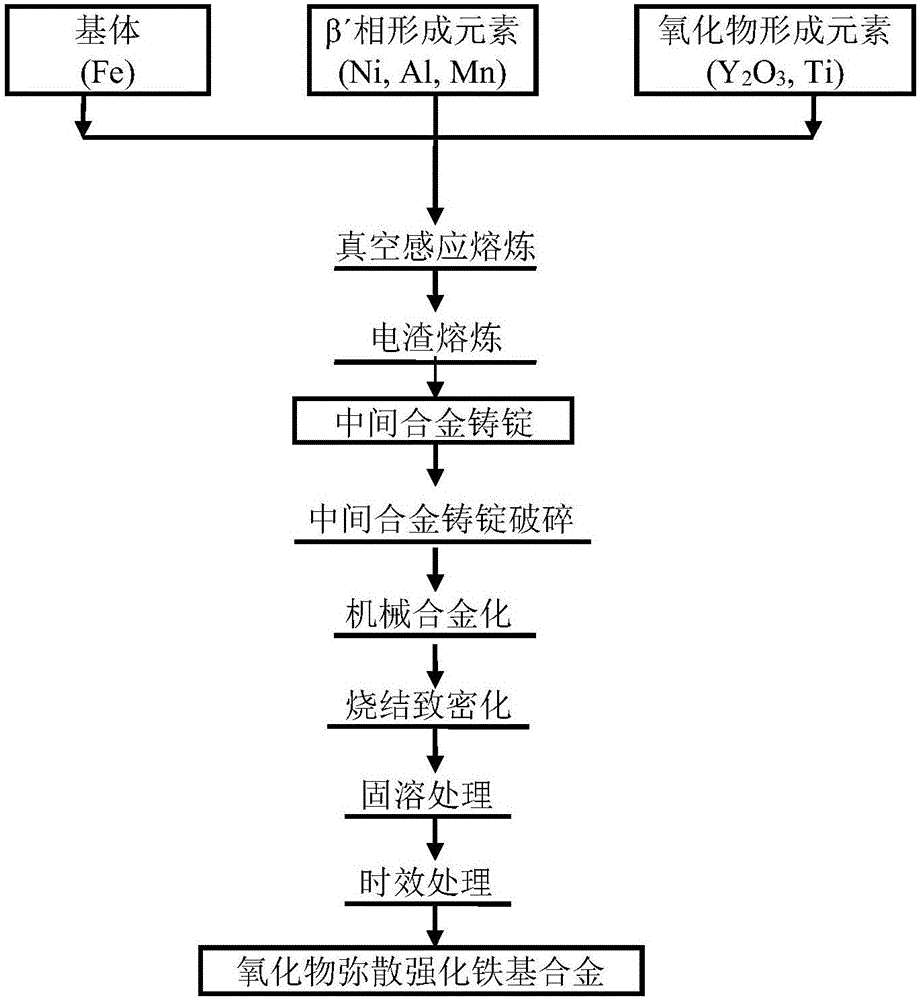

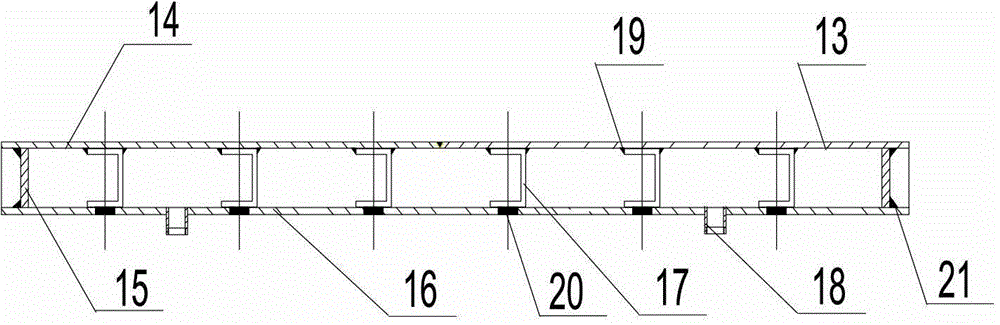

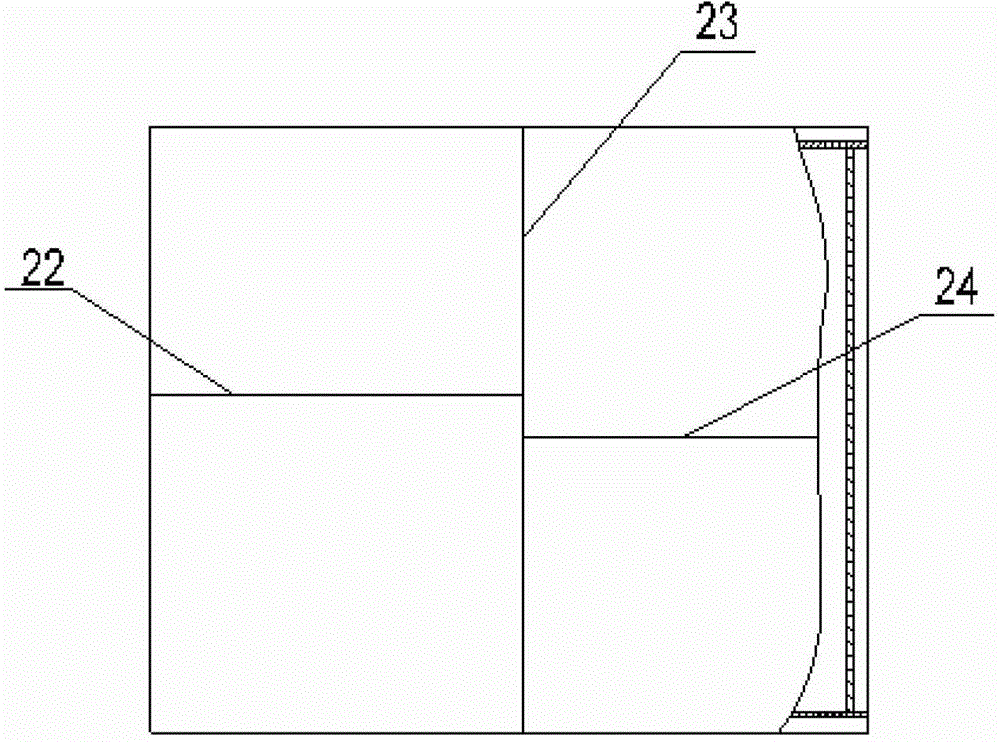

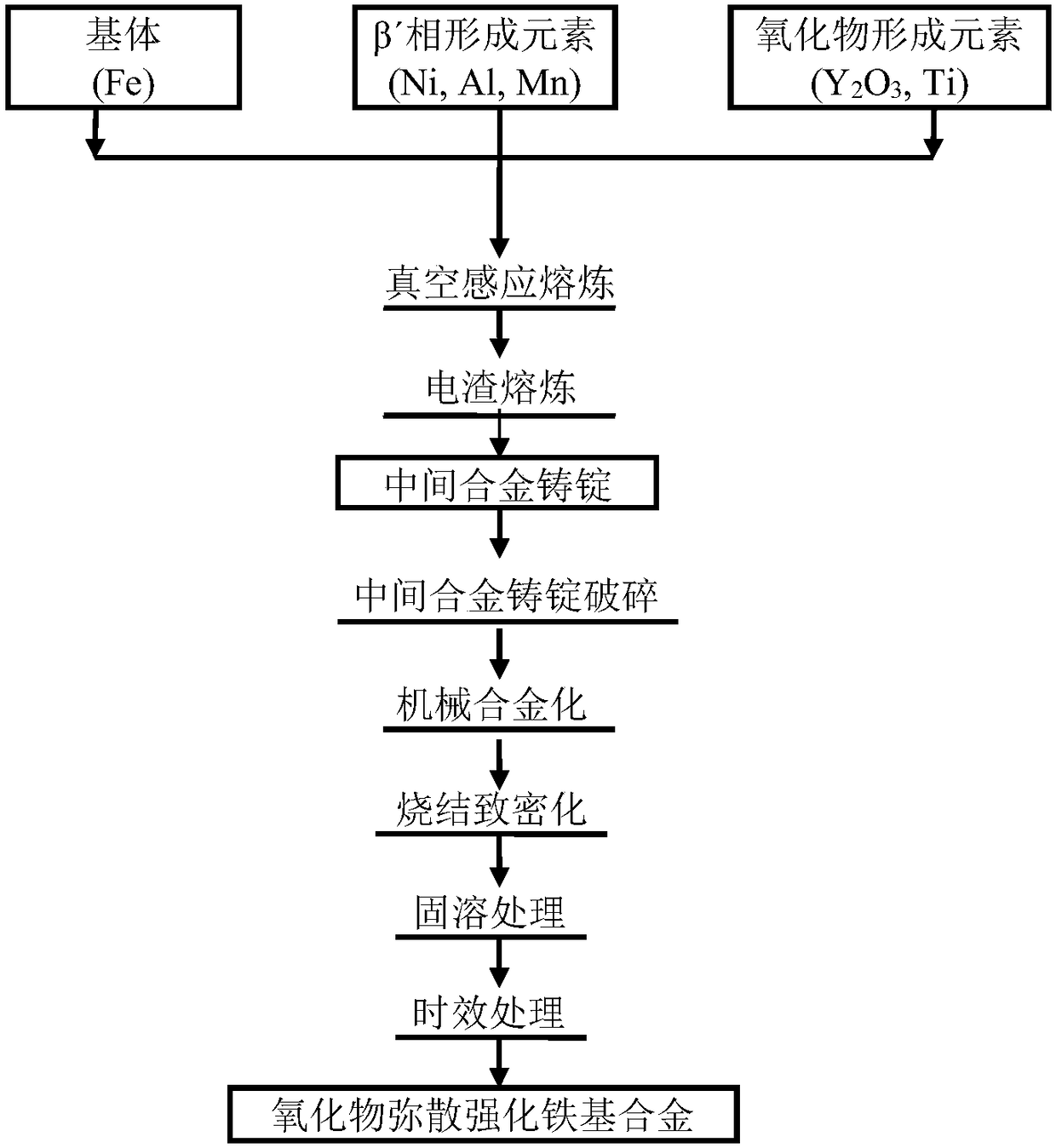

Method for preparing oxide dispersion strengthened iron-base alloy

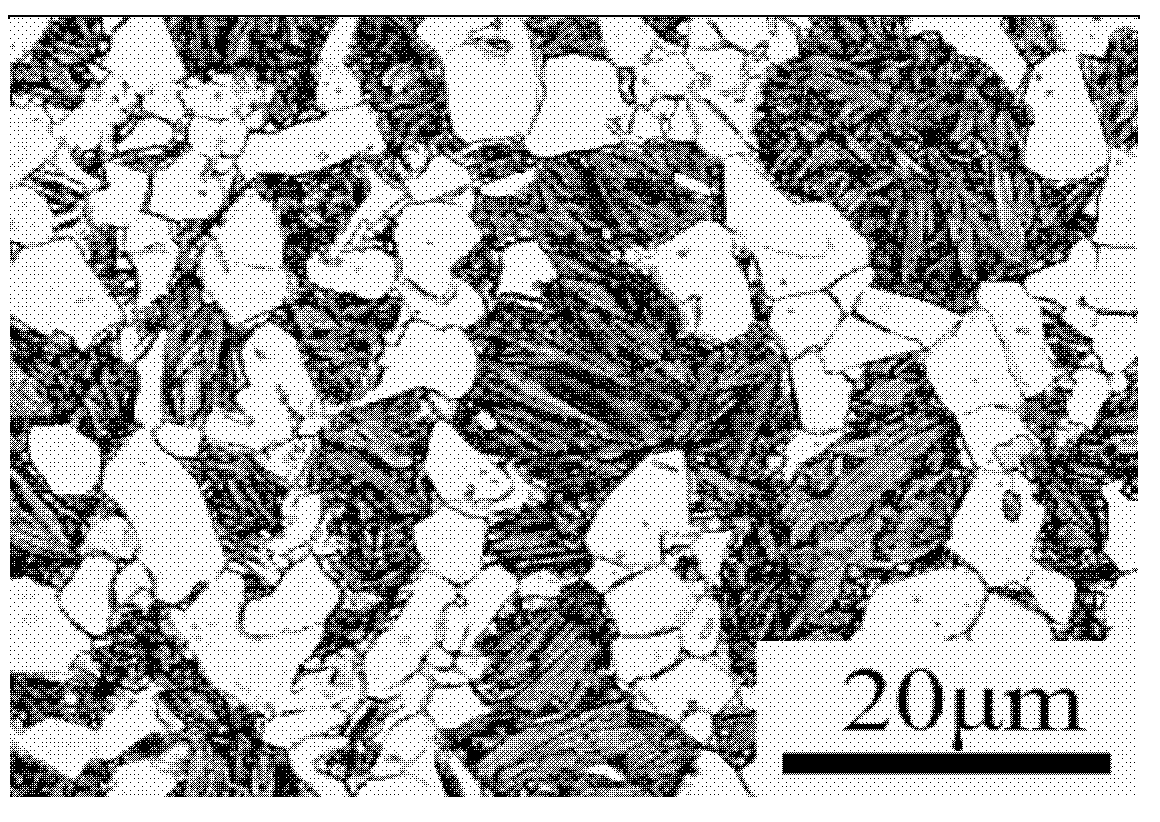

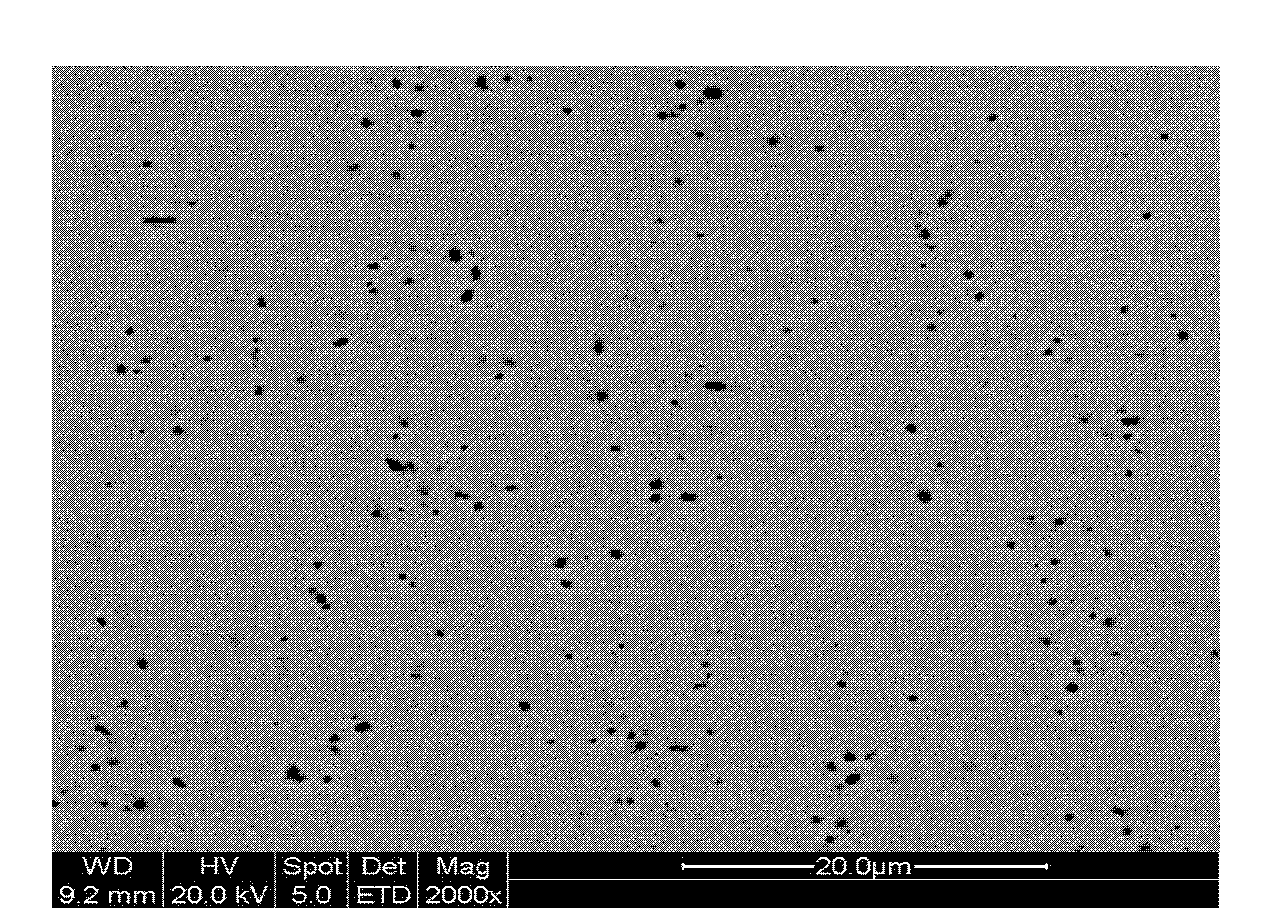

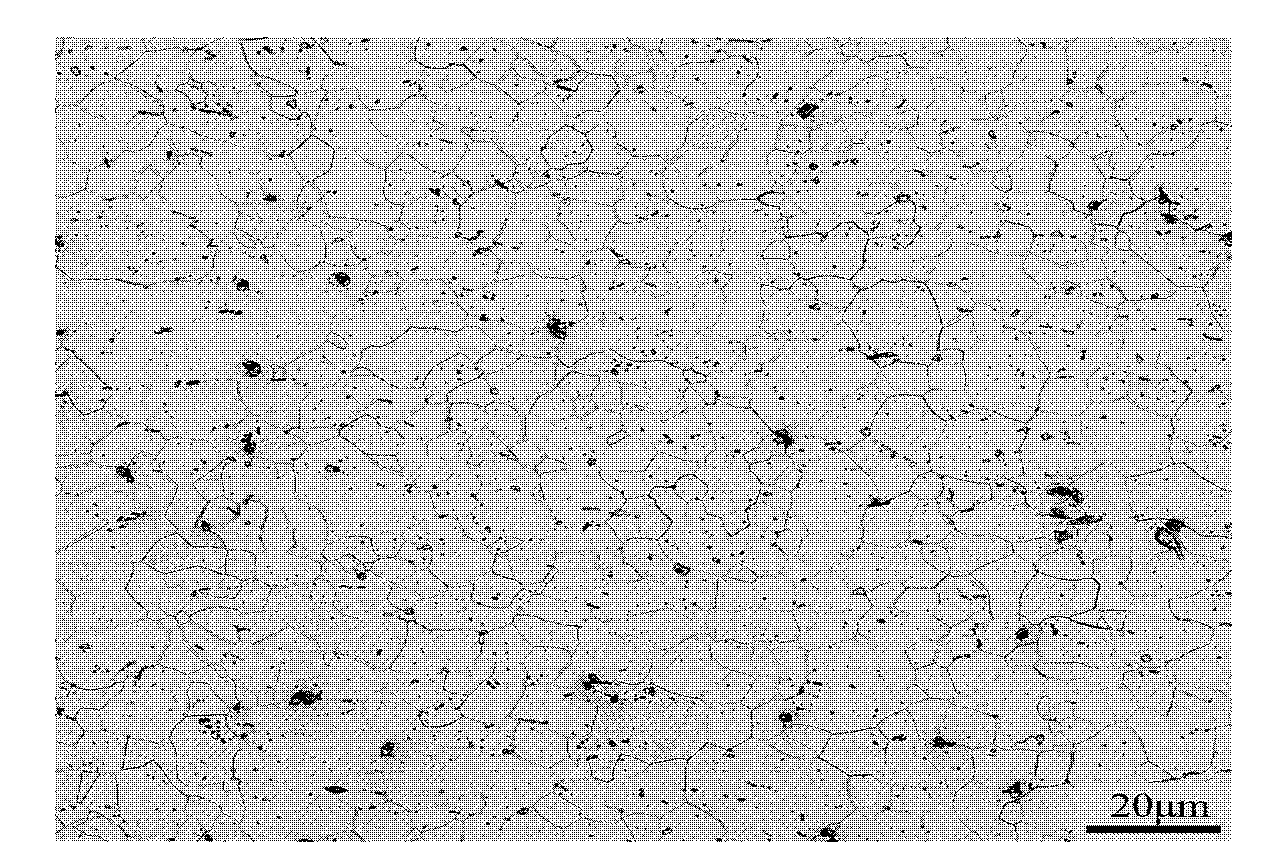

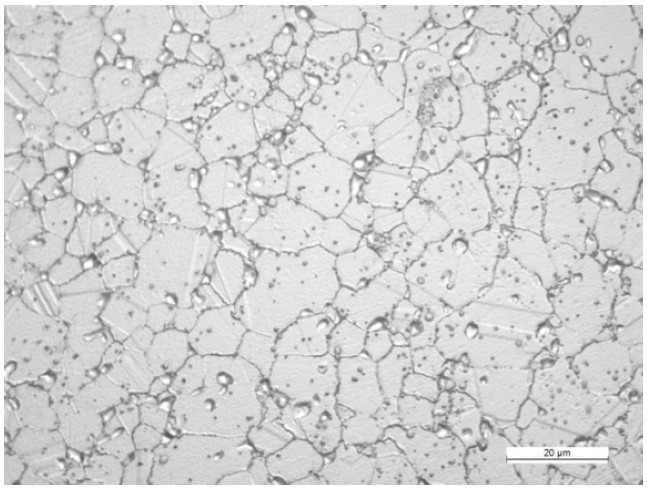

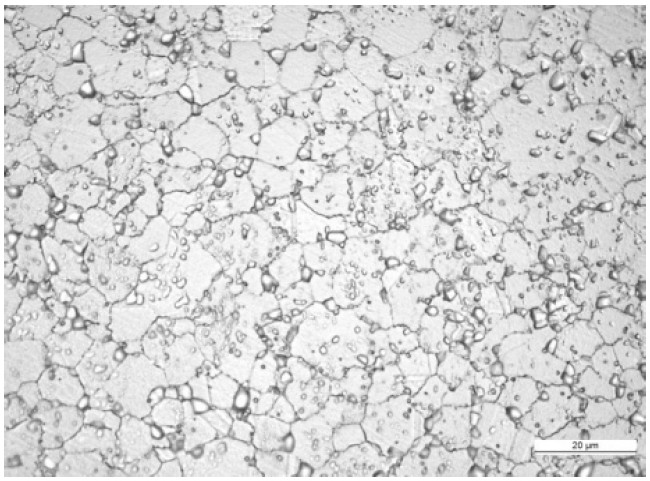

The invention discloses a method for preparing an oxide dispersion strengthened iron-base alloy, and belongs to the technical field of metal dispersion strengthening. The method comprises the following steps of: taking iron blocks, a Fe-Mn alloy and an Ni-Al alloy as raw materials, performing a vacuum smelting and electroslag smelting duplex process to obtain a pure intermediate alloy cast ingot; crushing the intermediate alloy cast ingot in a crusher with protective atmosphere to obtain intermediate alloy powder; and performing high-energy ball-milling on intermediate alloy powder, matrix powder and oxide powder to obtain the oxide dispersion strengthened iron-base alloy. Oxide dispersion strengthened iron-base alloy powder is subjected to hot isostatic pressing treatment and thermal treatment to obtain the final oxide dispersion strengthened iron-base alloy. The method adopts the duplex smelting process, so that content of oxygen and nonmetal impurities in cast ingot is effectively reduced; the alloyed intermediate alloy prevents oxidization of an element Mn, ball-milling time can be shortened and energy consumption is reduced. The prepared oxide dispersion strengthened iron-base alloy is co-strengthened by a L21 type Ni2AlMn intermetallic compound and an oxide dispersed phase, so that the strengthening effect is remarkable.

Owner:UNIV OF SCI & TECH BEIJING

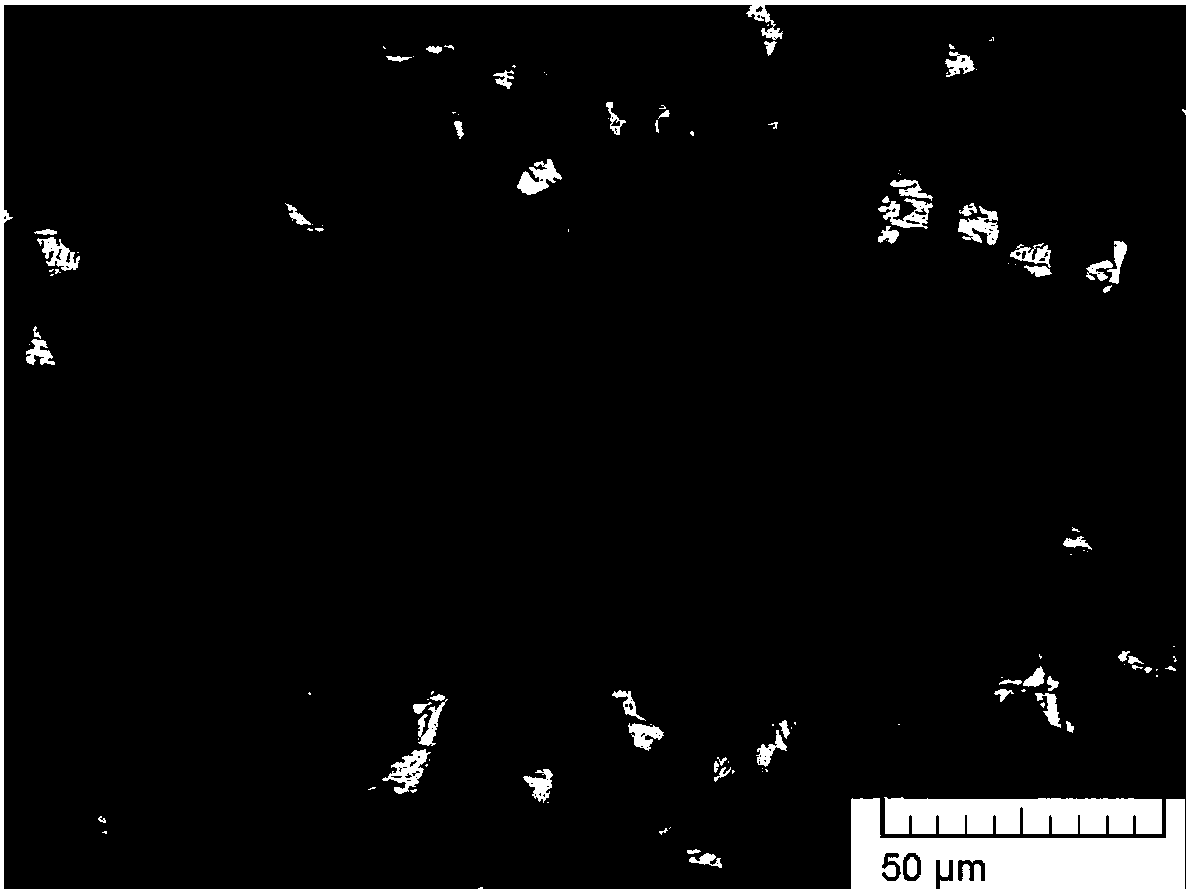

Production method of graphitized free-machining steel

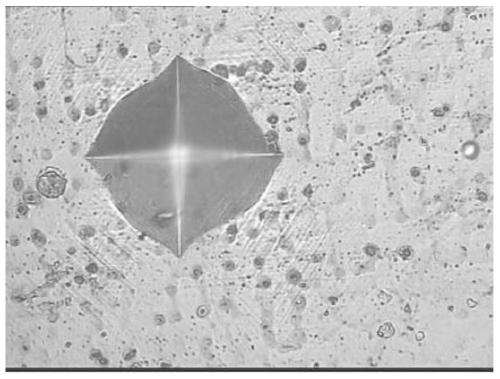

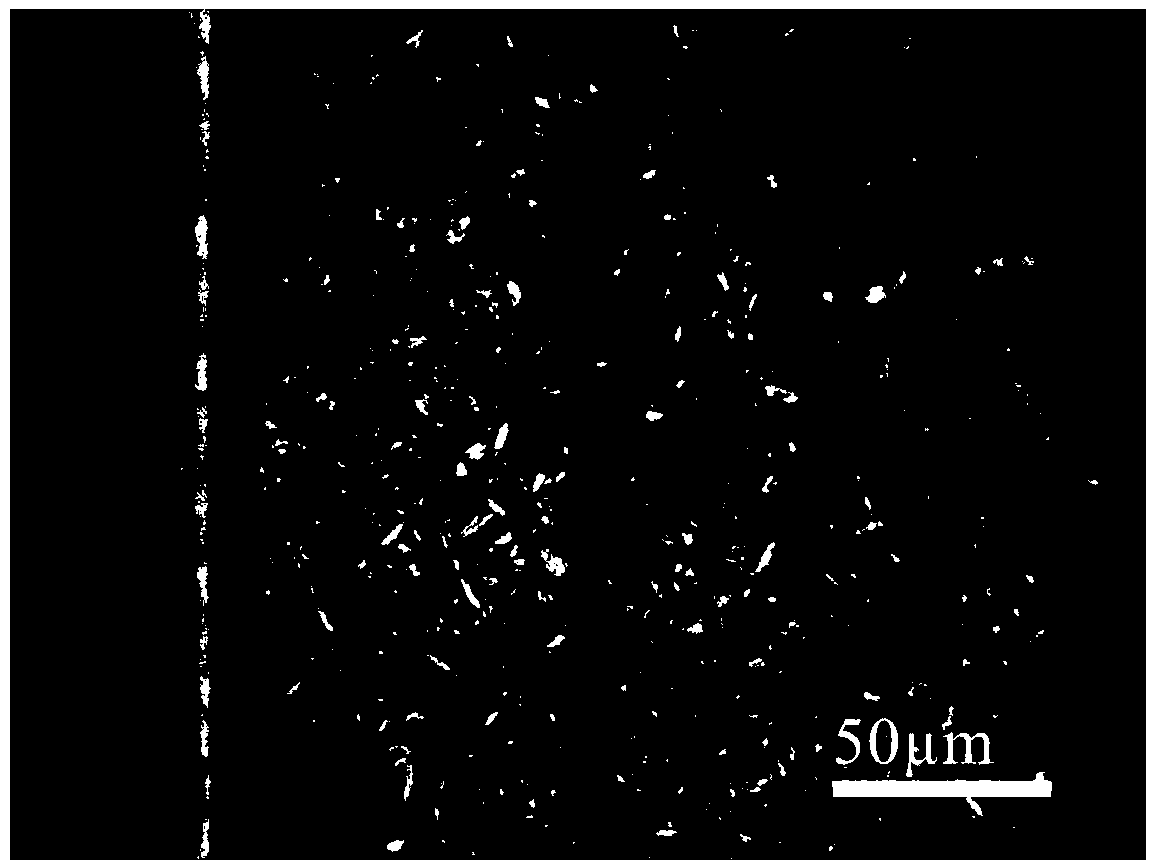

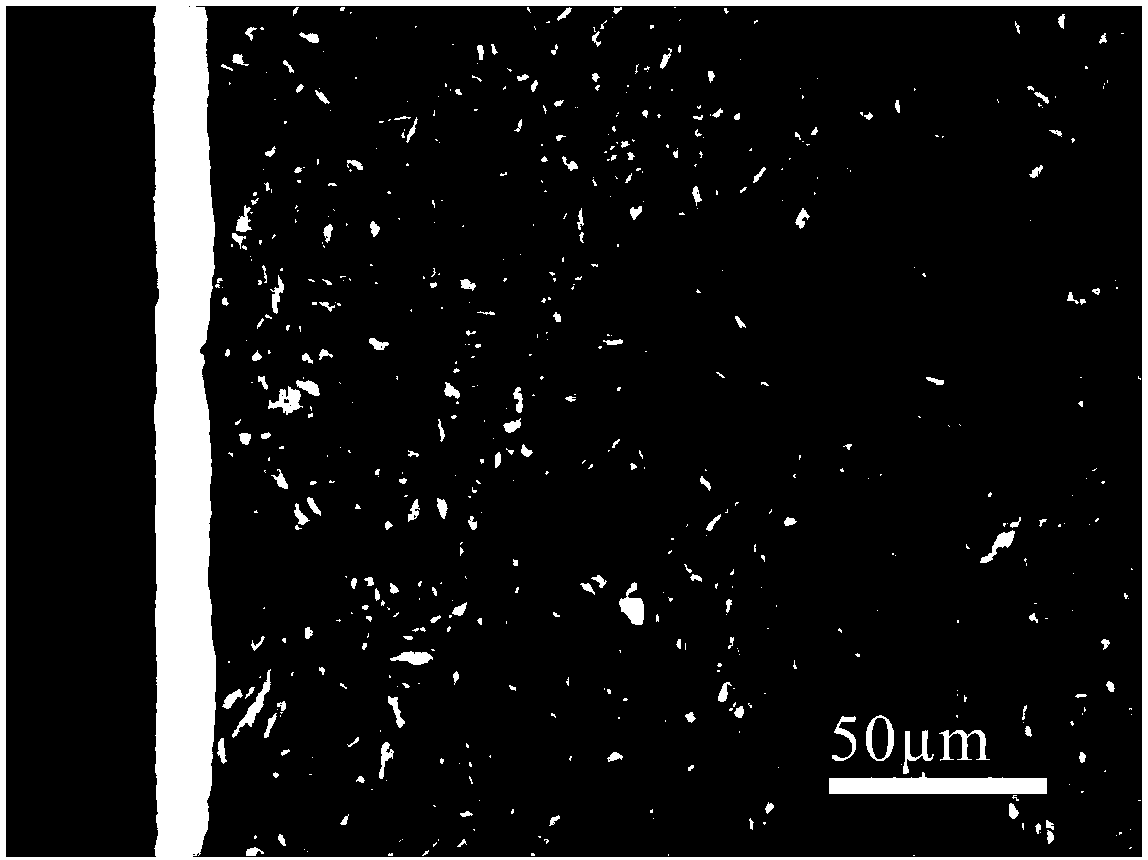

The invention relates to a method for producing graphitized free-machining steel from intermediate-carbon manganese-silicon steel, intermediate-carbon manganese-silicon-aluminum steel and the like. The method comprises the following steps: heating casting blanks; maintaining the temperature; cooling to 1050-1150 DEG C; roughly rolling: controlling the reduction percentage of each gate to be 20-40%; cooling to 850-1000 DEG C; carrying out precision rolling according to 4-6 gates; cooling in air; quickly cooling in water to room temperature; heating the precision rolling plate and maintaining the temperature; and cooling in air or cooling in a furnace to room temperature. By controlling the state of C atoms in steel and C content of austenite before tempering based on a process route of low-temperature rolling, relaxation and phase change, quenching and graphitization tempering, the invention converts all C atoms in the steel into graphite in a short time (5h). In the graphitized free-machining steel produced by the method, graphite grains in the organization are small in size and are uniform in distribution.

Owner:武钢集团有限公司

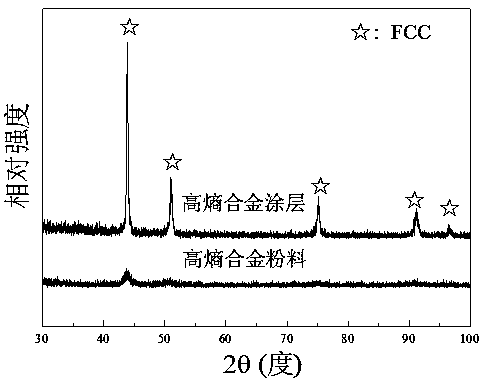

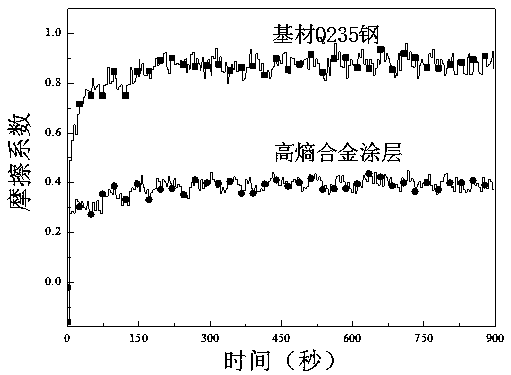

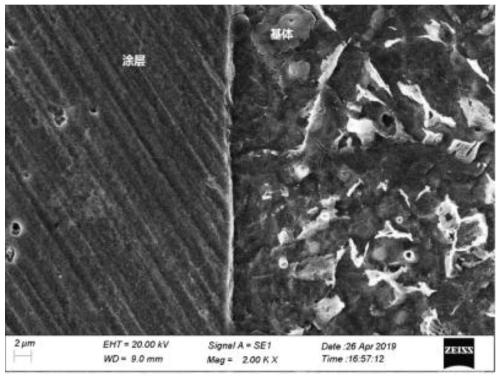

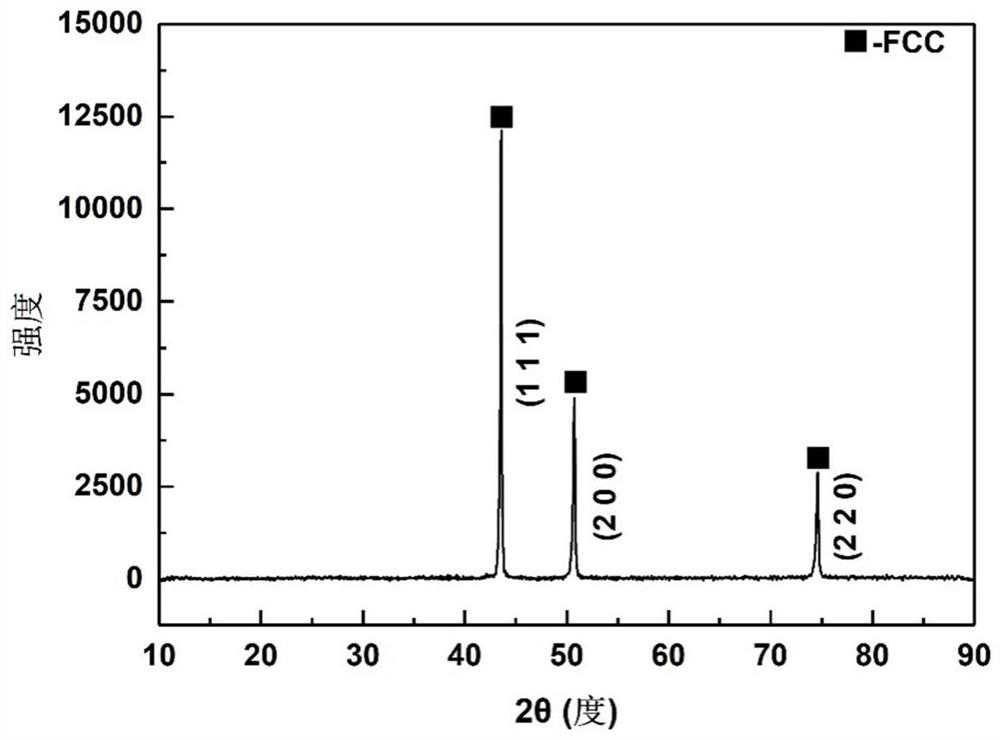

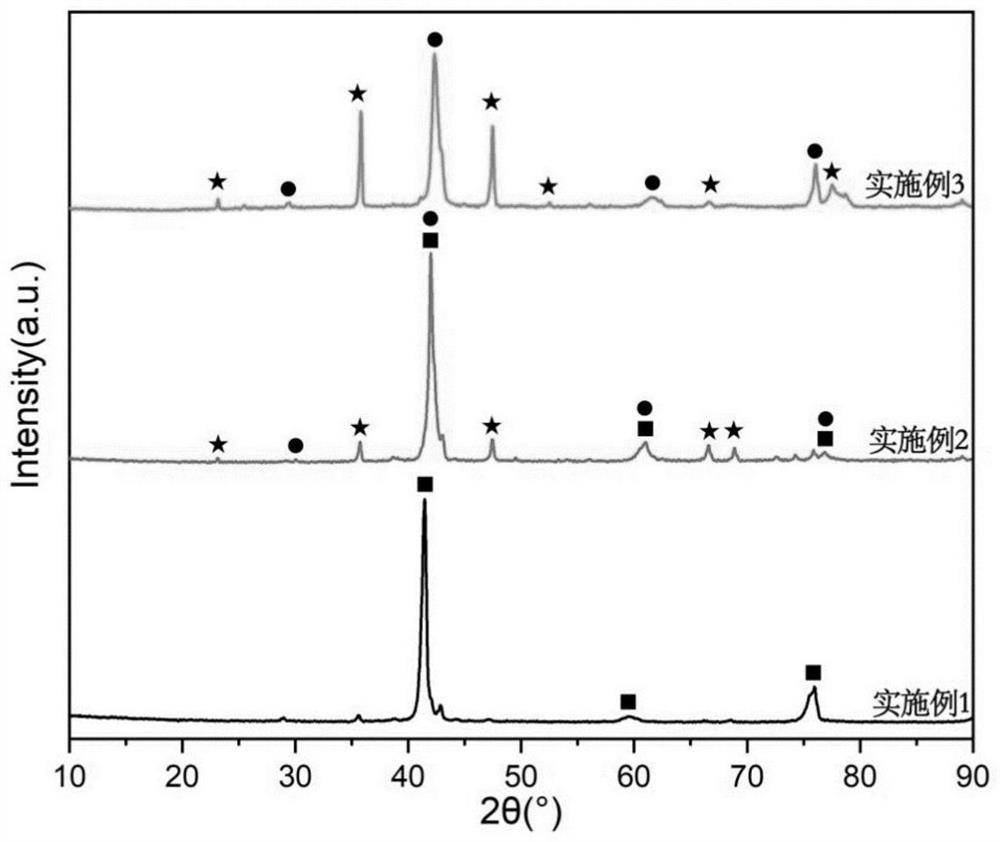

Preparation method for high-entropy alloy coating

ActiveCN105506613AHigh hardnessImprove wear resistanceHeat inorganic powder coatingHigh entropy alloysHardness

The invention relates to a preparation method for high-entropy alloy coating, and belongs to the technical field of alloy coating preparation. The preparation method comprises the following steps: placing high-entropy alloy powder presenting a single face-centered cubic structure on the surface of a steel base material; sintering by utilizing a vacuum hotpressing sintering furnace: firstly, adjusting the vacuum degree of a furnace chamber to be 1.0*10<-3> Pa, then rising the temperature to 800-1,000 DEG C with the temperature rising speed of 5-10 K / min, controlling the sintering pressure to be 20-40 Mpa, and sintering for 30-90 min. According to the preparation method, the high-entropy alloy powder presenting the single face-centered cubic structure is used as a raw material, the manner of vacuum hotpressing sintering which is simple in operation and common in used equipment is adopted for the first time to prepare the excellent high-entropy alloy coating; through control of the sintering process, the prepared CoCrFeNi coating still keeps the single face-centered cubic structure, and the hardness and the wear resistance of the coating are obviously improved.

Owner:UNIV OF JINAN

3D printing process method of high-strength aluminum manganese alloy

InactiveCN111659889ALow costImprove qualityAdditive manufacturing apparatusTransportation and packagingManganese3D modeling

The invention relates to a 3D printing process method of a high-strength aluminum manganese alloy, and belongs to the technical field of 3D printing. The 3D printing process method comprises the stepsthat firstly, a high-strength aluminum manganese alloy is mixed evenly by heating and melting; then the melted high-strength aluminum manganese alloy is subjected to a gas atomization technology to prepare high-quality aluminum manganese alloy powder, and aluminum manganese alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is conducted according to three-dimensional model data of parts in printing equipment introduced with inert gas, and a 3D printing product with the high-strength aluminum manganese alloy as a raw material is obtained. Compared with the prior art, according to the product printed by the process method, the relative density can reach more than 99%, the Vickers hardness can reach more than 140 HV, the tensile strengthcan reach more than 440 MPa, the elongation can reach 20%, after proper hear treatment, the hardness of a sample can reach more than 180 HV, the tensile strength can be further increased to more than565 MPa, and the elongation is maintained at or above 19%.

Owner:TONGJI UNIV

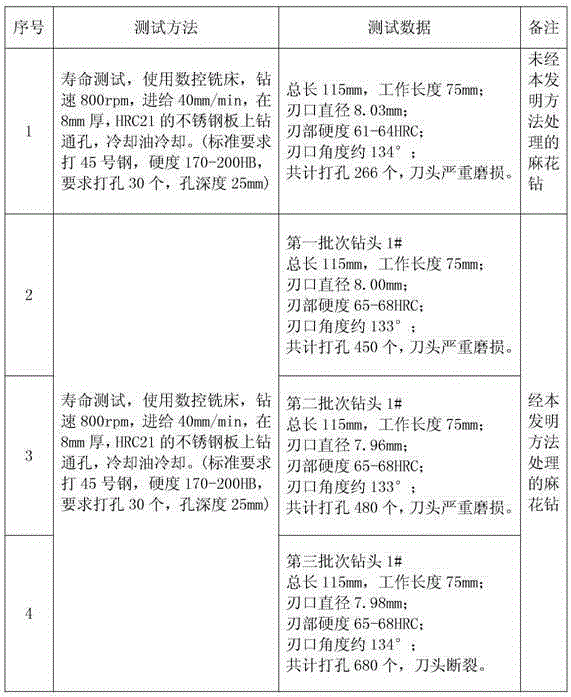

Rare earth catalytic permeation QPQ composition and method for manufacturing high-speed cutting tool by QPQ process

InactiveCN106319438AFast penetrationReduce processing timeSolid state diffusion coatingLiquid stateRare earth

The invention discloses a rare earth catalytic permeation QPQ composition and a method for manufacturing a high-speed cutting tool by a QPQ process, and belongs to the metal surface treatment technology. A nitriding speed of a conventional QPQ process is relatively slow, the thickness of a nitrided layer formed on the surface of a metal is relatively small, the hardness of a corresponding depth is also relatively smaller, and the grain size of the nitrided layer is relatively low; the rare earth catalytic permeation QPQ composition contains a QPQ base salt, and a salt solution of the QPQ base salt contains CNO<->; the composition contains a rare earth compound as a catalytic permeation agent; the rare earth compound is a solid mixture of La carbonate and Ce carbonate according to the weight ratio of 1:3 to 3:1. The method comprises that the rare earth catalytic permeation QPQ composition is melted into a liquid state to become the salt solution, and a workpiece is immersed into the salt solution for nitridation. Compared with a conventional QPQ salt, the permeation rate is increased; the formed compound layer is 10 [mu]m or more deeper than a conventional QPQ compound layer, and the hardness of the corresponding depth is increased by 100 HV or more; the structure of the nitrided layer is increased by 1 grain size grade.

Owner:HANGZHOU GREAT STAR IND CO LTD

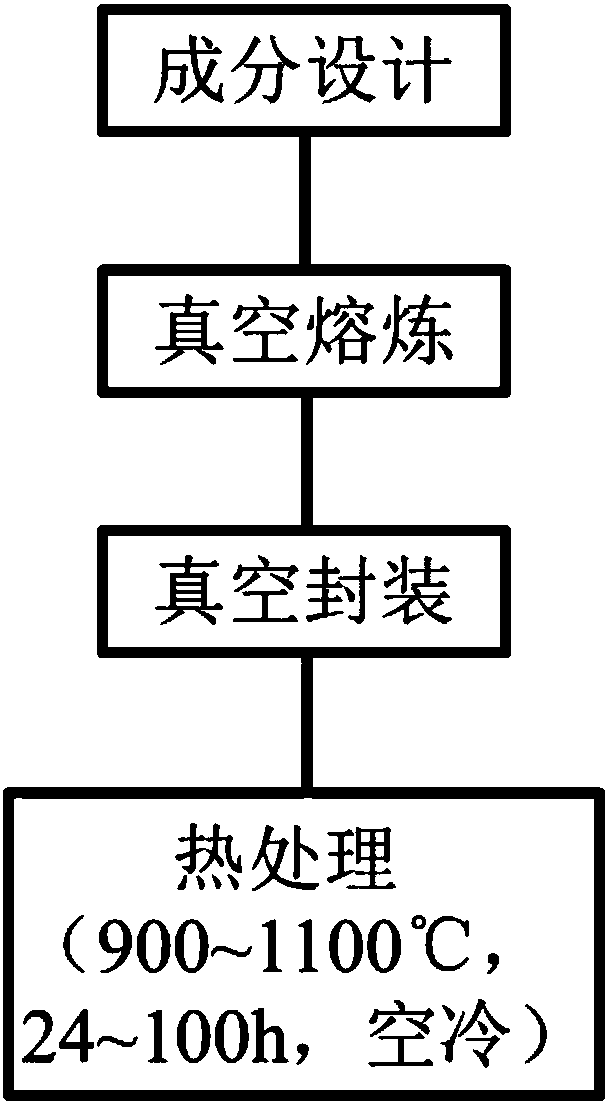

Zr-Ti-Cr-V complex phase hydrogen storage alloy and preparing method thereof

The invention discloses a Zr-Ti-Cr-V complex phase hydrogen storage alloy and a preparing method thereof. The hydrogen storage alloy is composed of Zr, Ti, Cr and V; the atomic ratio is 1:0.2-0.6:0.1-0.6:1.8-2.1. Through component design of the non-stoichiometric ratio, through vacuum heat treatment, a C15 type Laves phase, V-rich solid solution and Zr-rich solid solution coexistence complex phasestructure with the specific proportion can be formed in the alloy. The alloy room temperature hydrogen absorbing amount can reach 2.80wt%, and the excellent hydrogen absorbing dynamics property can be achieved.

Owner:江西新节氢能源科技有限公司

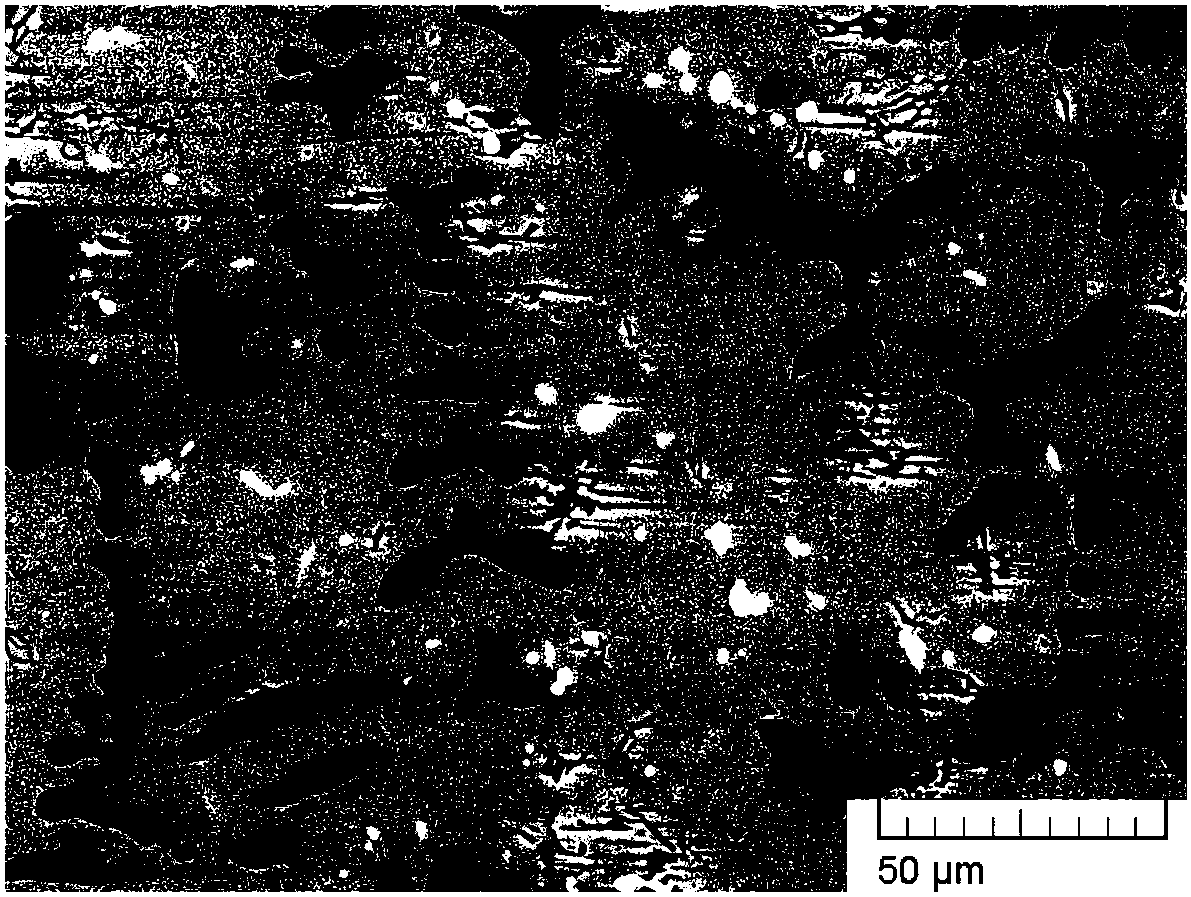

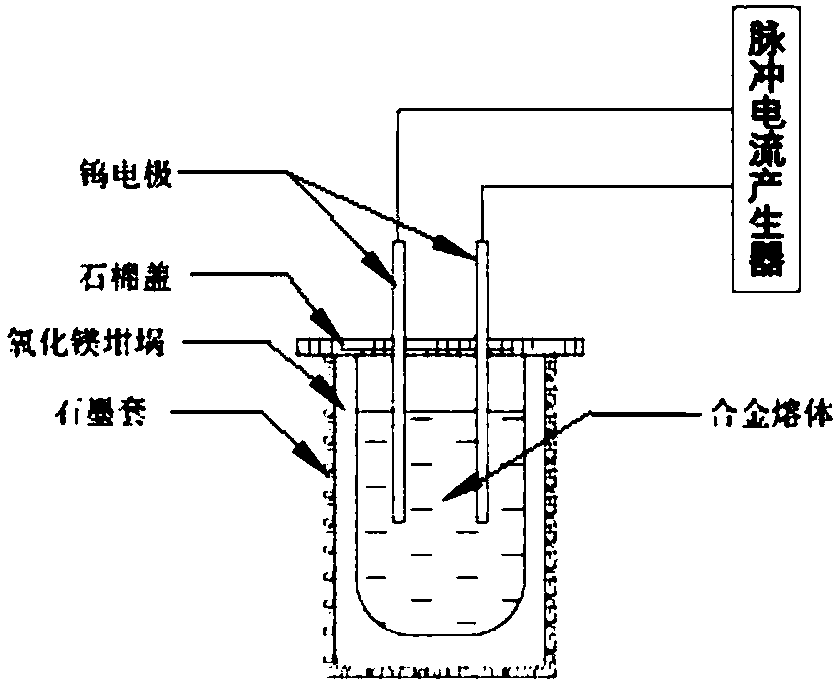

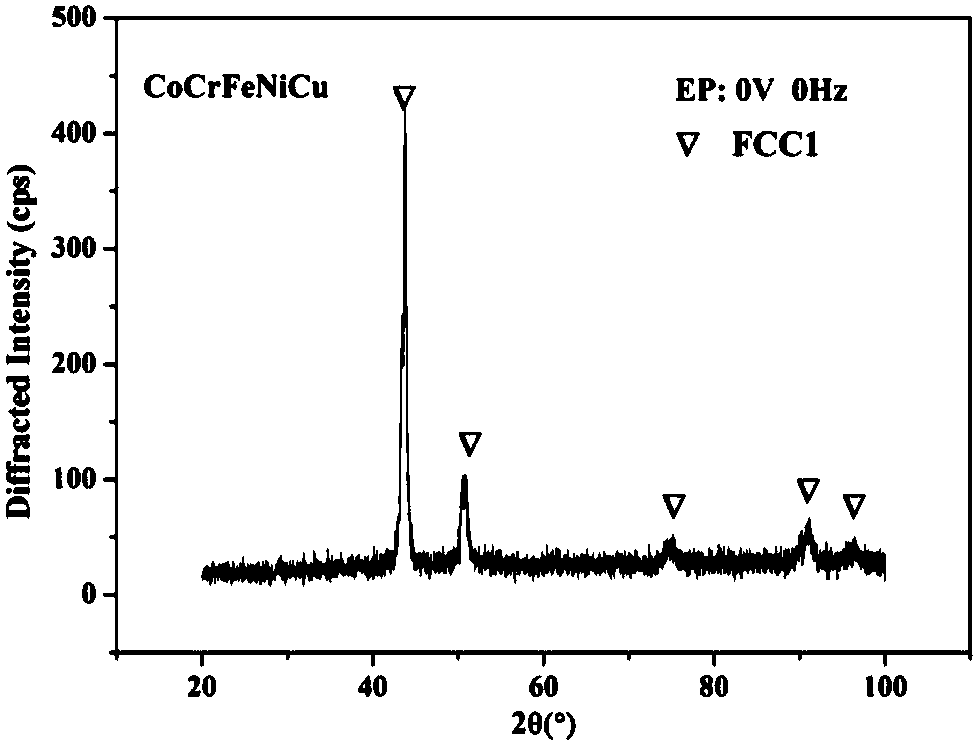

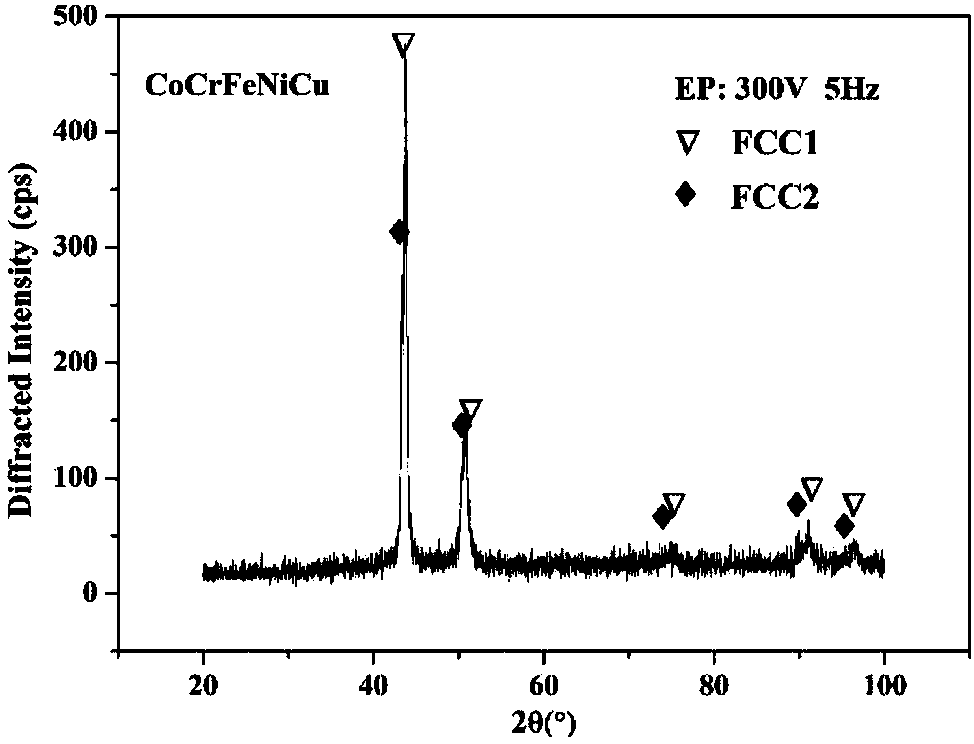

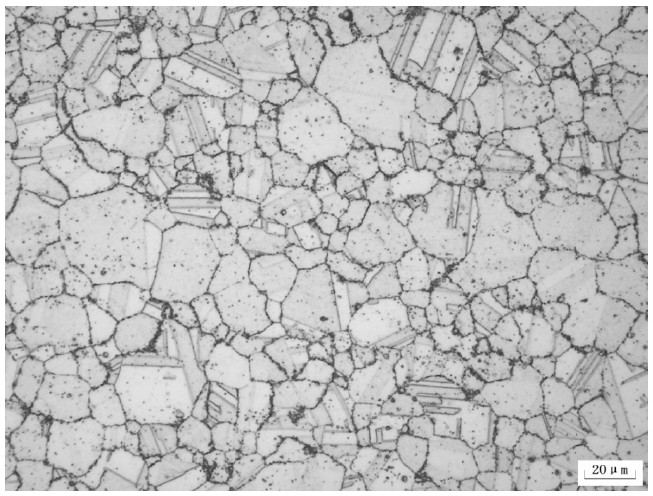

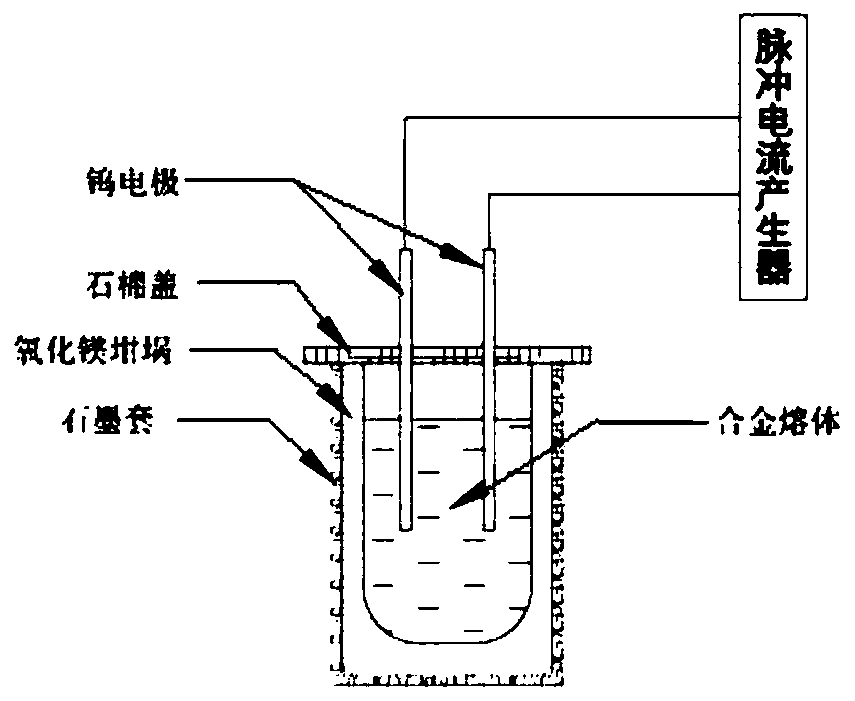

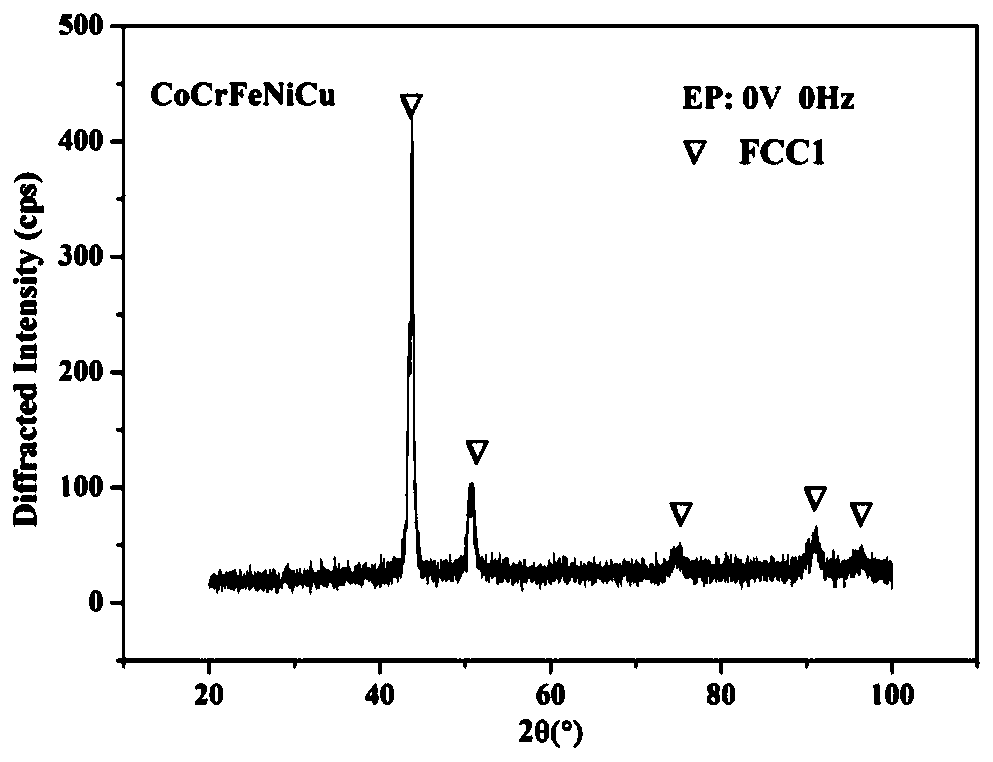

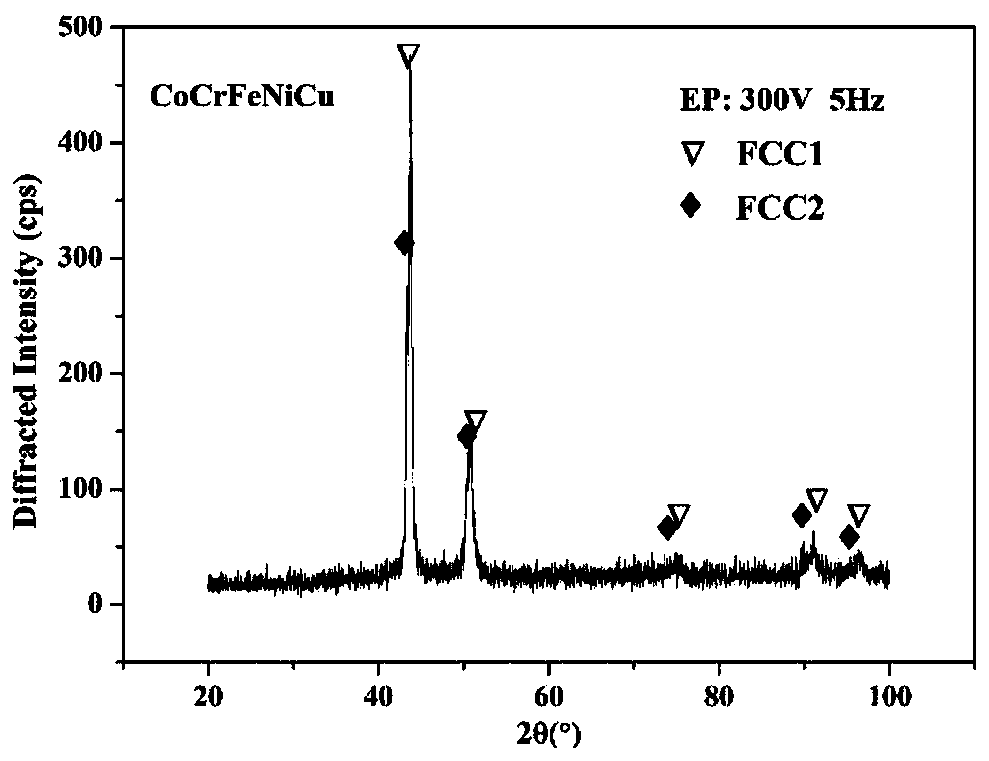

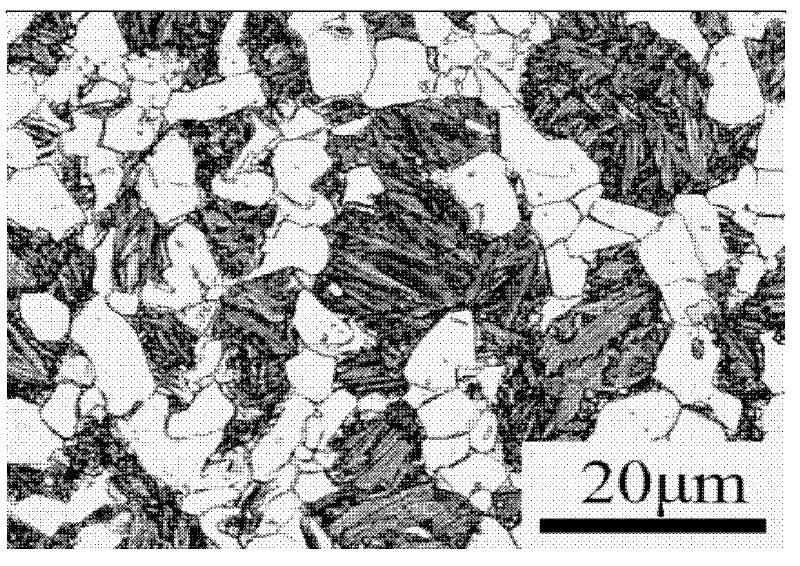

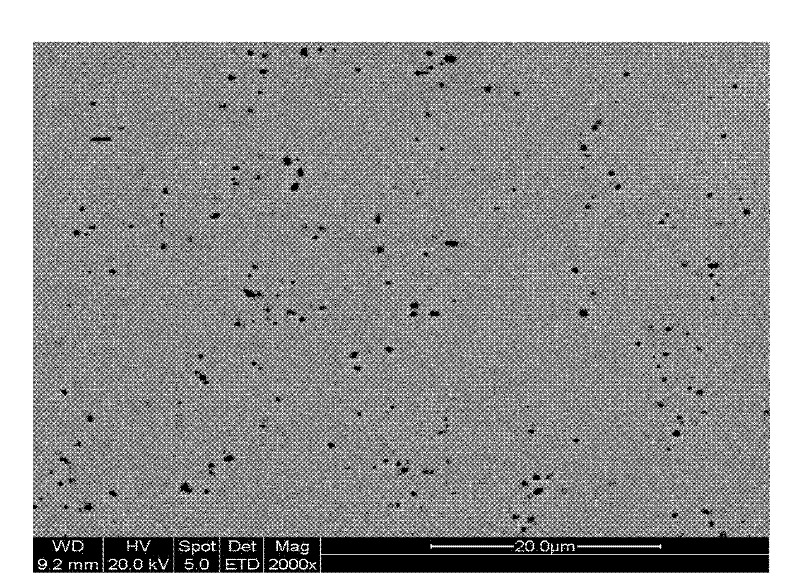

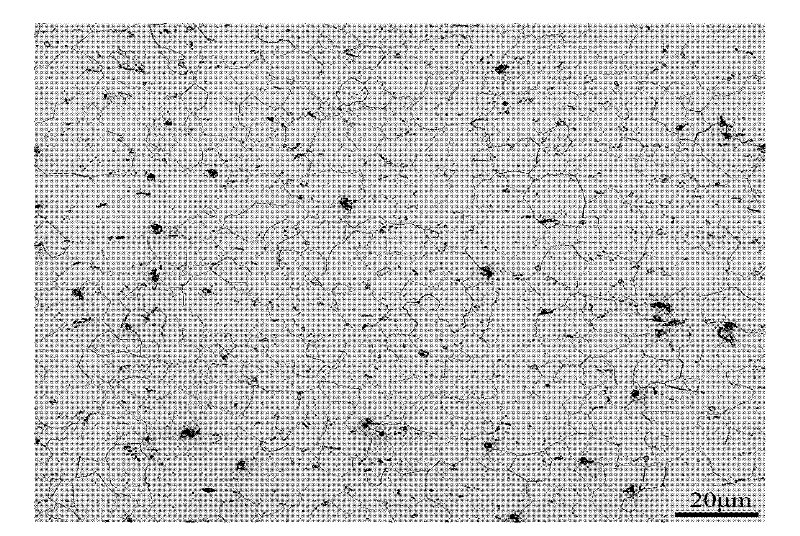

Method of regulating performance of CoCrFeNiCu high-entropy alloy

The invention discloses a method of regulating performance of a CoCrFeNiCu high-entropy alloy. The method is characterized by comprising the following steps: smelting raw materials Co, Cr, Fe, Ni andCu in equal molar weight with elements in a crucible by means of a smelting method, and smelting the melt at a high temperature continuously for no less than 10min; stretching a pulse electrode into the melt stopped in heating, and processing the pulse electrode for 30-90s with pulse, the voltage of which is not smaller than 100V and the frequency of which is not smaller than 5Hz, to obtain a CoCrFeNiCu high-entropy alloy; and naturally cooling the CoCrFeNiCu high-entropy alloy to room temperature and taking out a cast ingot from the crucible to obtain a CoCrFeNiCu high-entropy alloy cast ingot. According to the method disclosed by the invention, an electric pulse treatment method is applied to a preparation process of the high-entropy alloy to prepare the high hardness and high strength alloy, the yield strength of which is improved by about 233.3% and the breaking strength of which is improved by about 18.4%; and meanwhile, the invention provides a regulating method which is small inenergy consumption, low in cost, simple to operate or short in treatment period and can regulate the performance of the alloy.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

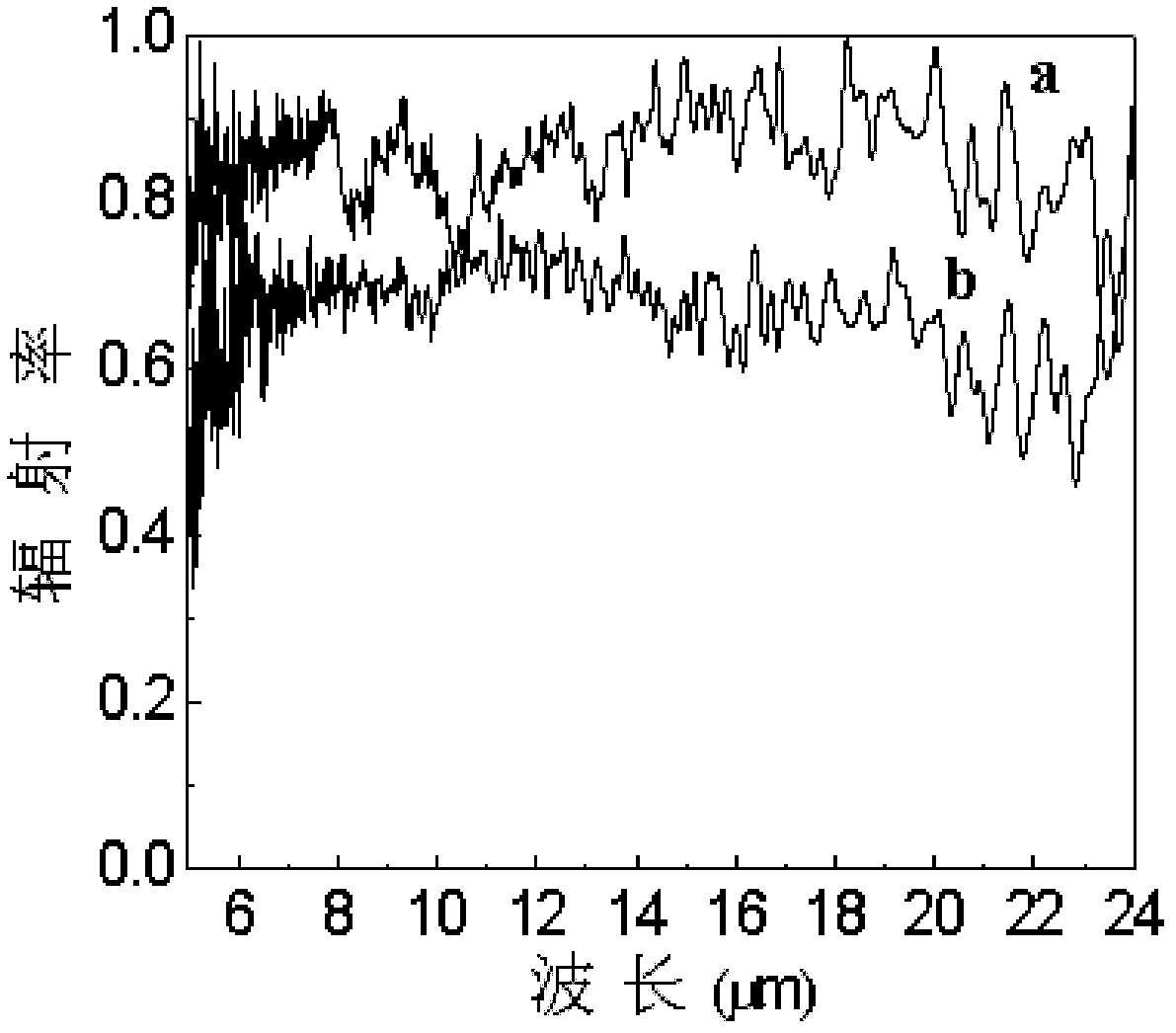

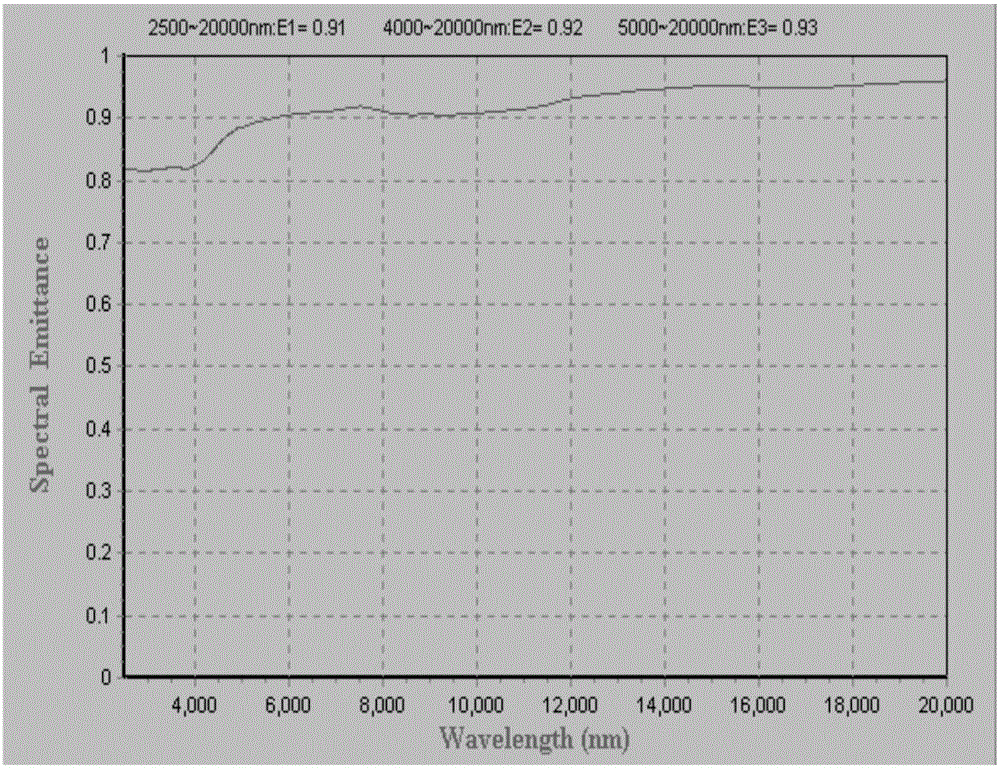

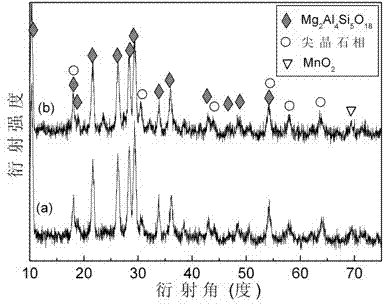

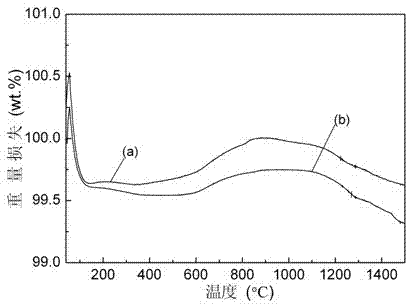

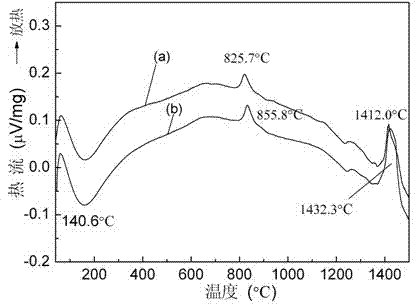

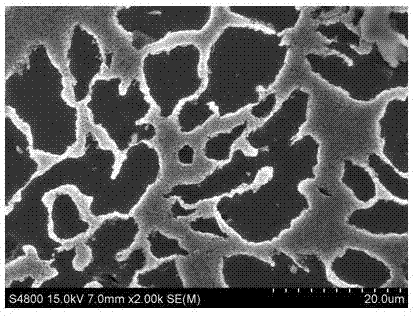

Powder material with high infrared radiance in broadband and preparation method of power material

InactiveCN102633494AImprove infrared radiation performanceLarge lattice distortionAir atmosphereBrick

The invention discloses a powder material with high infrared radiance in a broadband and the preparation method of the powder material. The powder material is of a cordierite material doped with Ba<2+> or / and Fe<3+>. The preparation method of the powder material comprises the steps of: firstly dissolving pioneer raw materials and doped raw materials which form the cordierite into an alcohol-water mixture solvent, stirring, drying, and then prefiring at the temperature of 600-1,000 DEG C under air atmosphere; and forging at the temperature of 1,150-1,350 DEG C; and finally cooling to room temperature along with a furnace. The powder material disclosed by the invention has radiance higher than 0.8 in the infrared waveband of 5-24mu m when being heated to 100 DEG C, especially, the most of infrared radiance is higher than 0.9 in the waveband of 14-20mu m and obviously higher than that of cordierite matrix, thus meeting application requirements in the fields of infrared interior wall insulating coating, infrared ceramic glazed bricks, industrial furance insulating coating and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

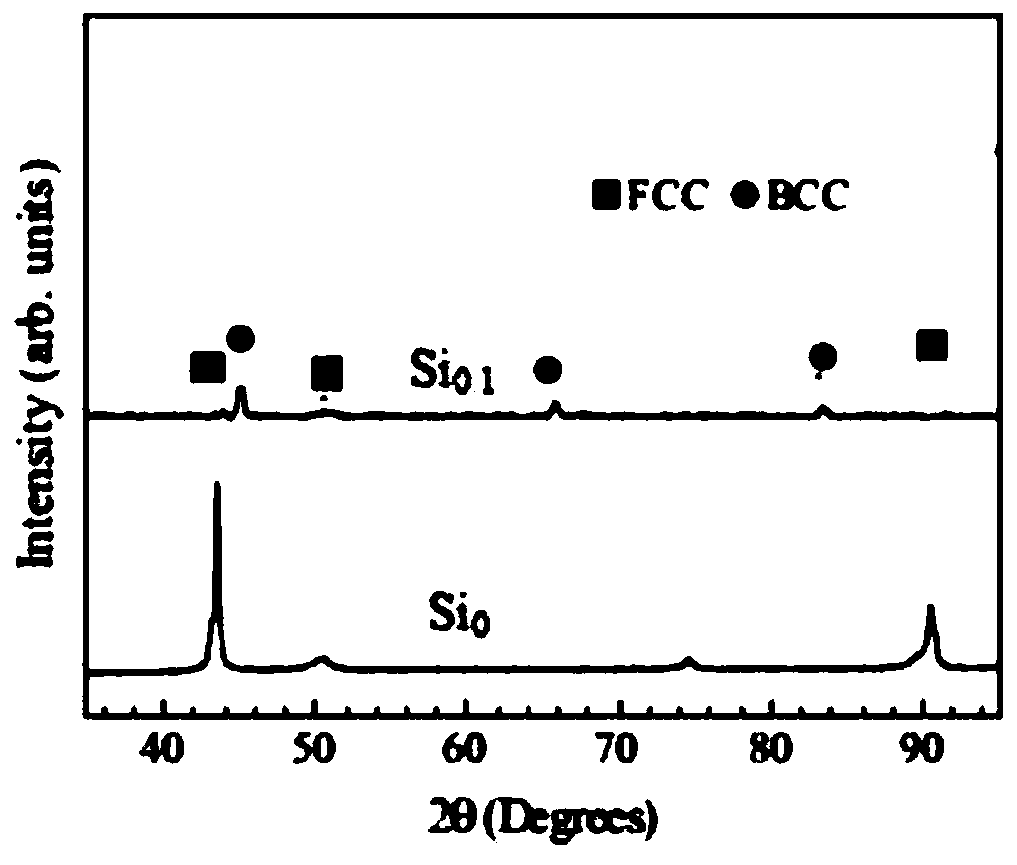

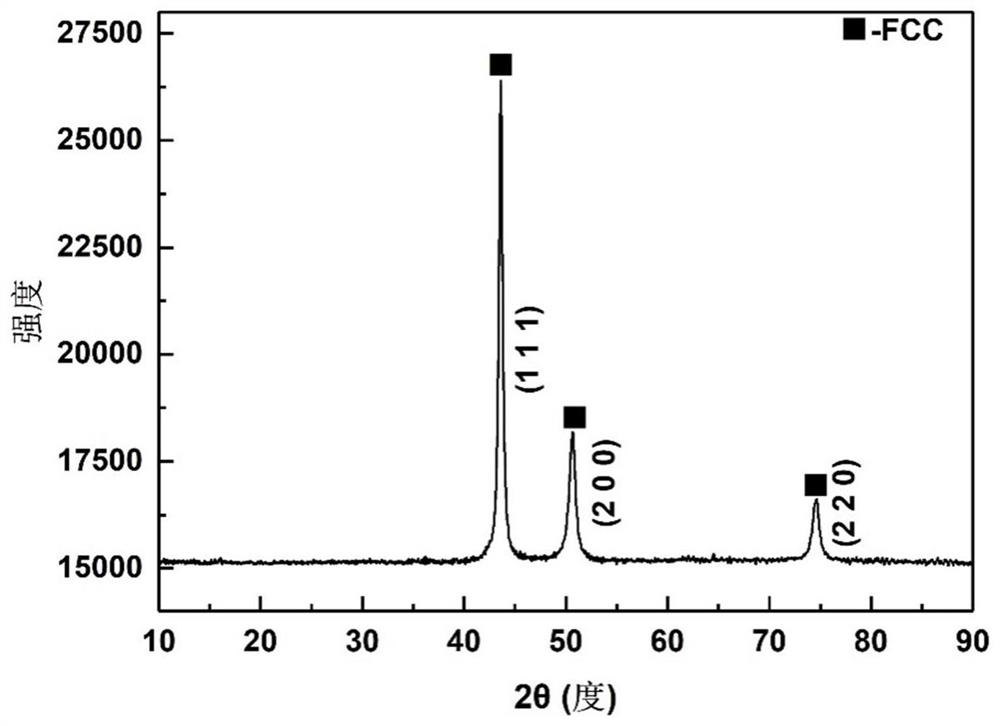

Silicon-containing high-entropy alloy coating and preparation method thereof

InactiveCN110306186ALarge lattice distortionHigh hardnessMetallic material coating processesCoated surfaceHigh entropy alloys

The invention provides a silicon-containing high-entropy alloy coating and a preparation method thereof, and belongs to the field of alloy coatings. According to the silicon-containing high-entropy alloy coating and the preparation method thereof, a silicon element is used as a secondary element and also is a gap element to be added into CoCrCuFeMn high-entropy alloy so that the quite good high-temperature softening resistance can be achieved through a gap effect of non-metal elements, then the lattice distortion of the high-entropy alloy of the kind can be increased, a solid solution strengthening effect can be achieved, the silicon element and the main element can also form a silicide to be dispersed in the alloy structure, a dispersion strengthening effect is generated, so that the hardness and the wear resistance of the high-entropy alloy of the kind are improved; the self-fluxing element Si is added so that the fluidity of the alloy in the liquid state can be improved, and then the macroscopic morphology of the surface of the coating is improved; and part of the Si can replace Cr with the large atom radius, so that the lattice distortion effect of the alloy is intensified, then the peak value of the FCC phase in the high-entropy alloy structure is changed, through the addition of the Si, the BCC phase can be converted to the FCC phase in the high-entropy alloy, so that thevolume fraction of the FCC phase is promoted to be increased.

Owner:NANCHANG UNIV +1

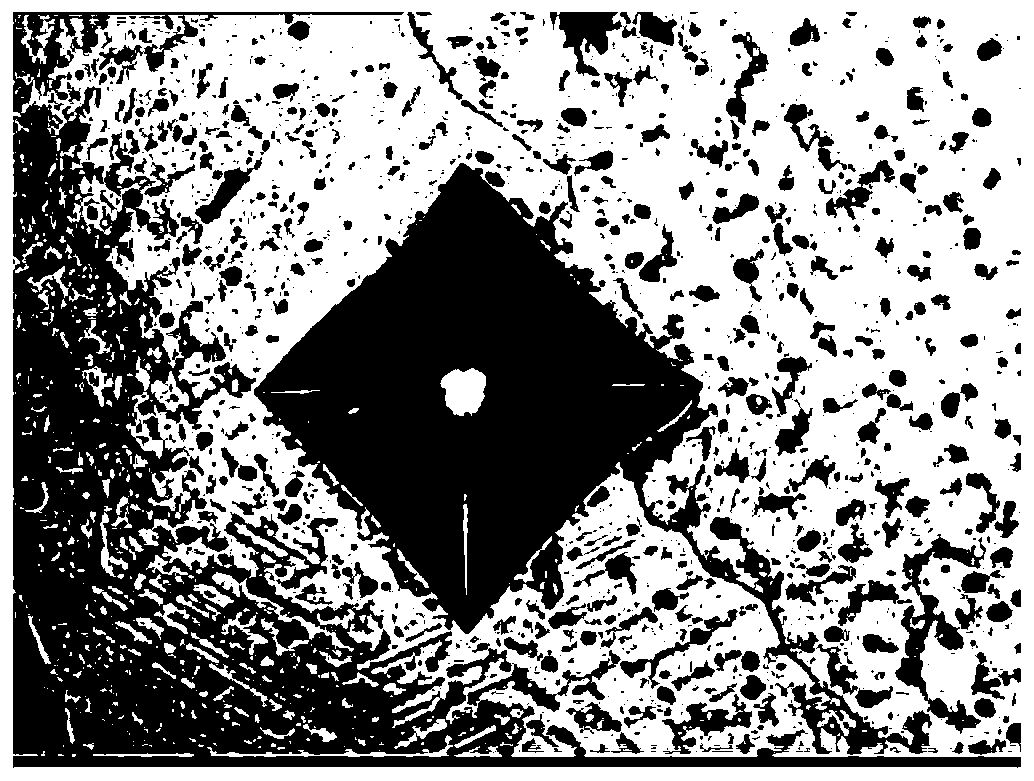

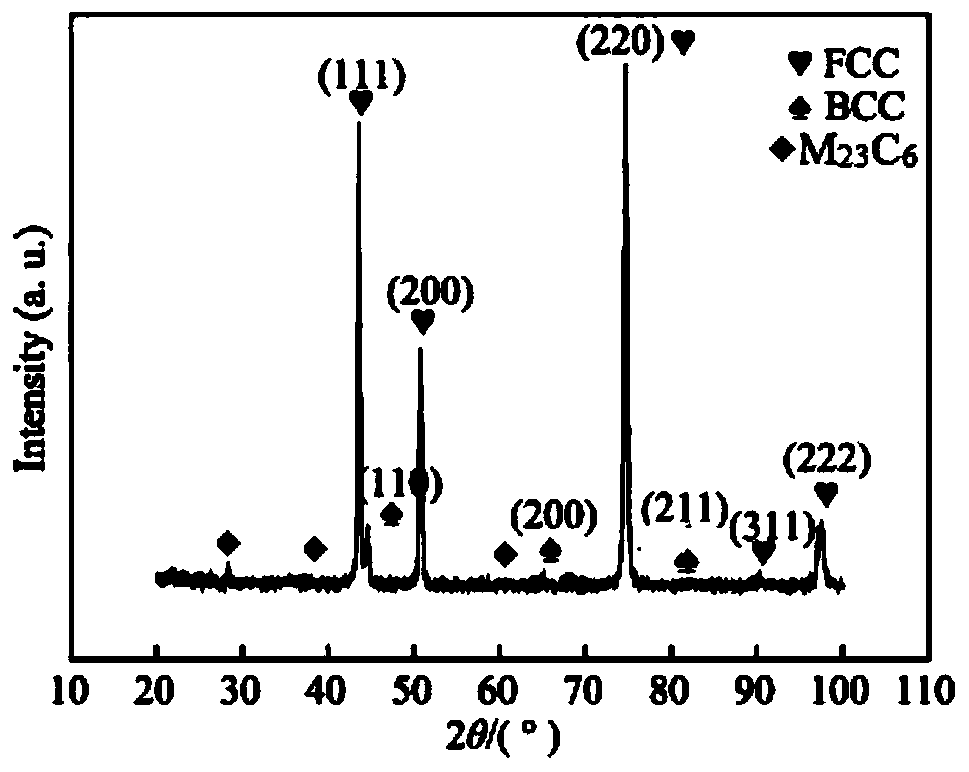

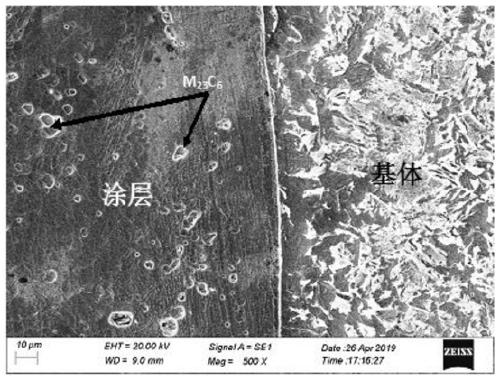

Carbonic high-entropy alloy coating and preparation method thereof

ActiveCN110241354ALarge lattice distortionHigh hardnessMetallic material coating processesHigh entropy alloysCarbide

The invention provides a carbonic high-entropy alloy coating and a preparation method thereof, and belongs to the field of alloy coatings. Co, Cr, Cu, Fe and Mn are adopted as main elements, a carbon element (C) is adopted as a secondary element, C is an interval element and is added into the CoCrCuFeMn high-entropy alloy, the stacking fault energy of the alloy can be improved through the interval effect of the non-metal element, lattice distortion of the high-entropy alloy is improved, the solid solution strengthening effect is achieved, the carbon element can form a carbide with the main elements, for example, Fe-C, Cr-C M23C6 or M7C3 carbides are formed and dispersed into alloy tissue, the dispersion reinforcing effect is generated, and the high-entropy alloy hardness and abrasion resistance are improved; meanwhile, the high-entropy alloy structure formed by the main elements is BCC+FCC, a dual-phase solid solution is formed, after the C element is added, and the phase structure type cannot change; due to the dual-phase solid solution, the high-entropy alloy has the higher strength, and the hardness of the carbonic high-entropy alloy coating is improved.

Owner:NANCHANG UNIV

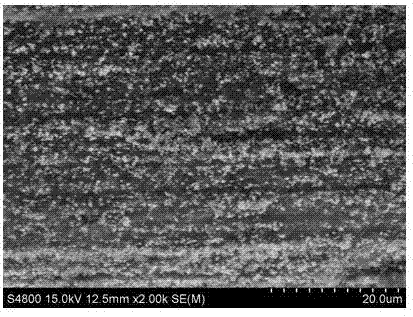

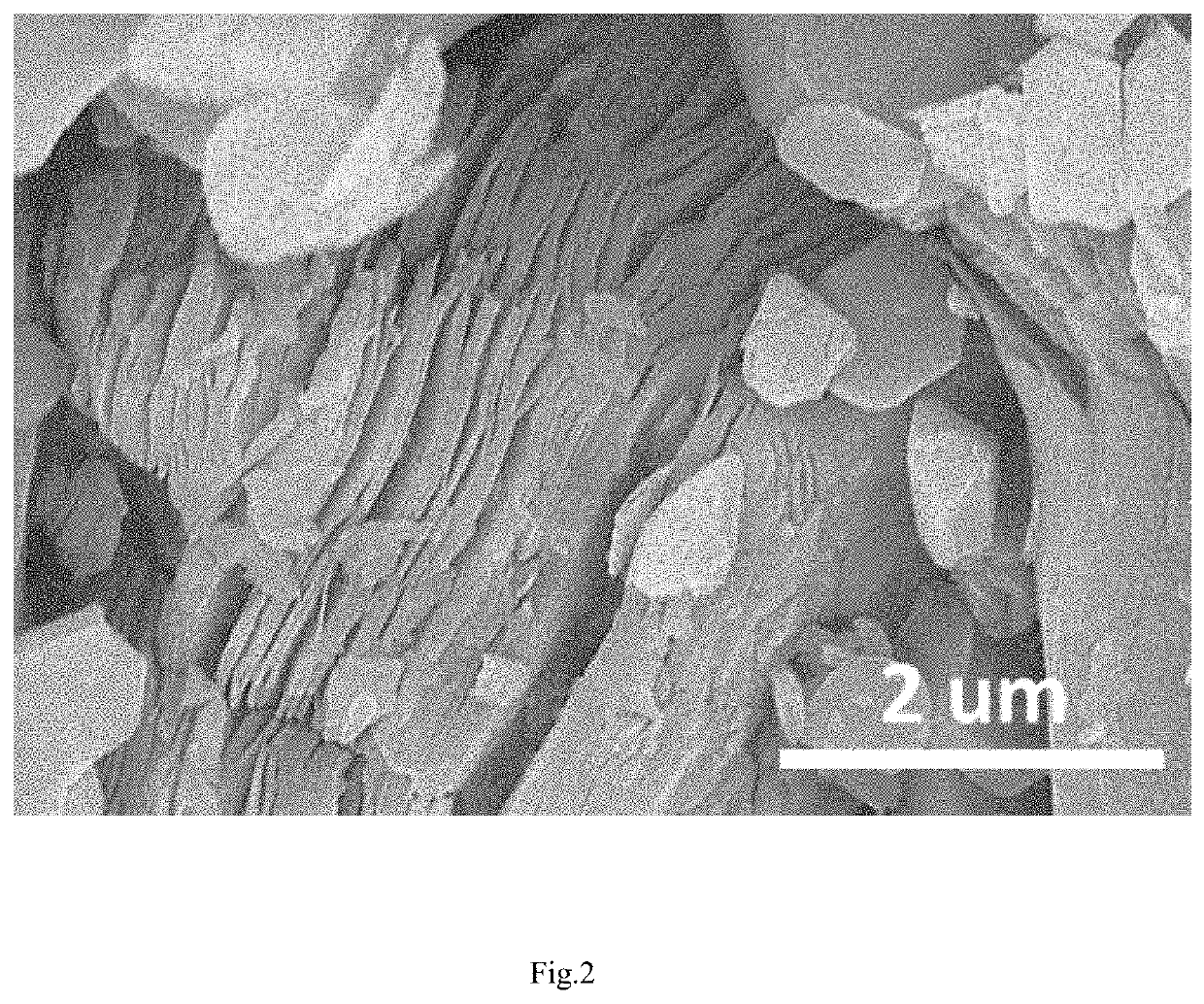

Composite pretreatment process for improving ion nitriding efficiency

InactiveCN108611589AOvercome the shortcomings of thinness and low nitriding efficiencyGrain refinementSolid state diffusion coatingLayer thicknessPermeation

The invention relates to a composite pretreatment process for improving ion nitriding efficiency. The process comprises the following steps: original-state steel is machined and cut as a sample; the sample is thermally refined and polished for ultrasonic cleaning in organic solvent and drying; the sample is impacted by laser, and is positioned in an ion nitriding furnace for vacuumizing; hydrogenis introduced for sputtering; preoxidation and ion nitriding are performed in succession; and the sample is cooled to the room temperature along with the furnace. The process has the following beneficial effects: through the first phase of laser impact, grains on the surface layer of a material are refined, the dislocation density is increased, and an ideal channel is provided for dispersion of nitrogen atoms; in the second phase, a thin layer of oxide film is formed on the surface of the material, and the oxide film is gradually reduced by hydrogen in the ion nitriding process to form a looseporous dispersion channel, so that the catalytic permeation effect is further achieved; and through laser impact and pre-oxidation compound pretreatment, the nitriding efficiency and the permeation layer thickness can be greatly improved within shorter time, so that prominent efficiency and energy saving advantages are achieved.

Owner:CHANGZHOU UNIV

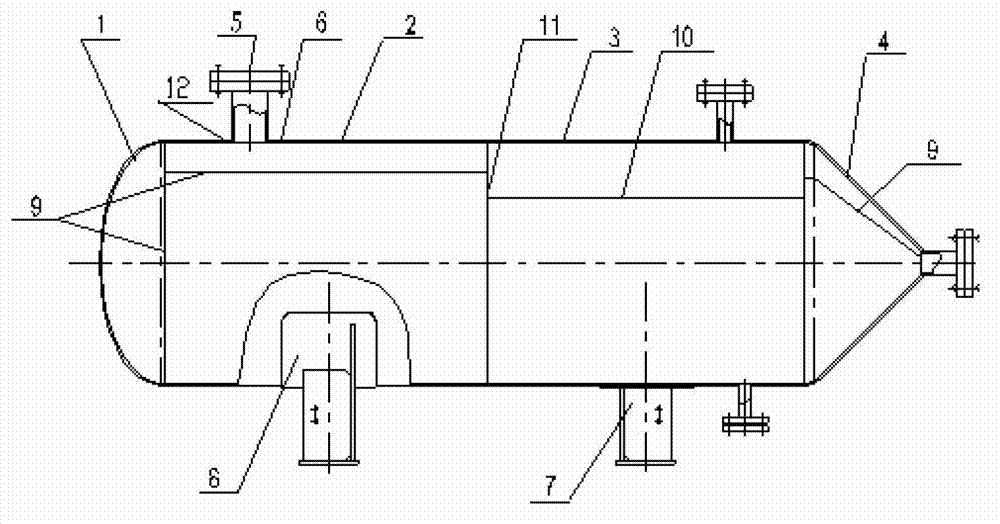

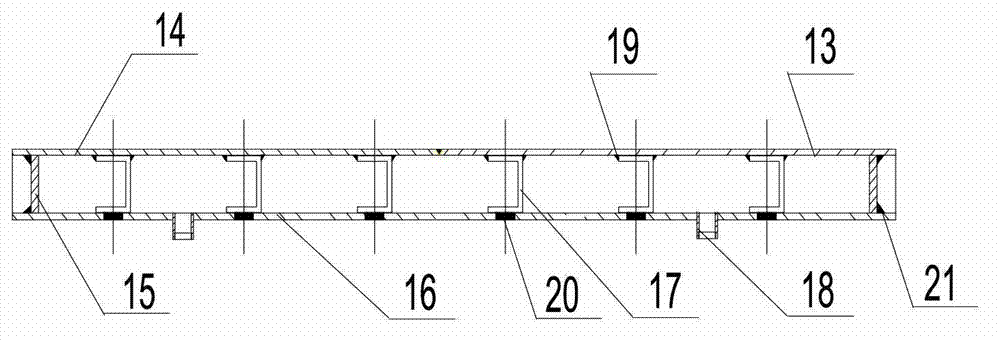

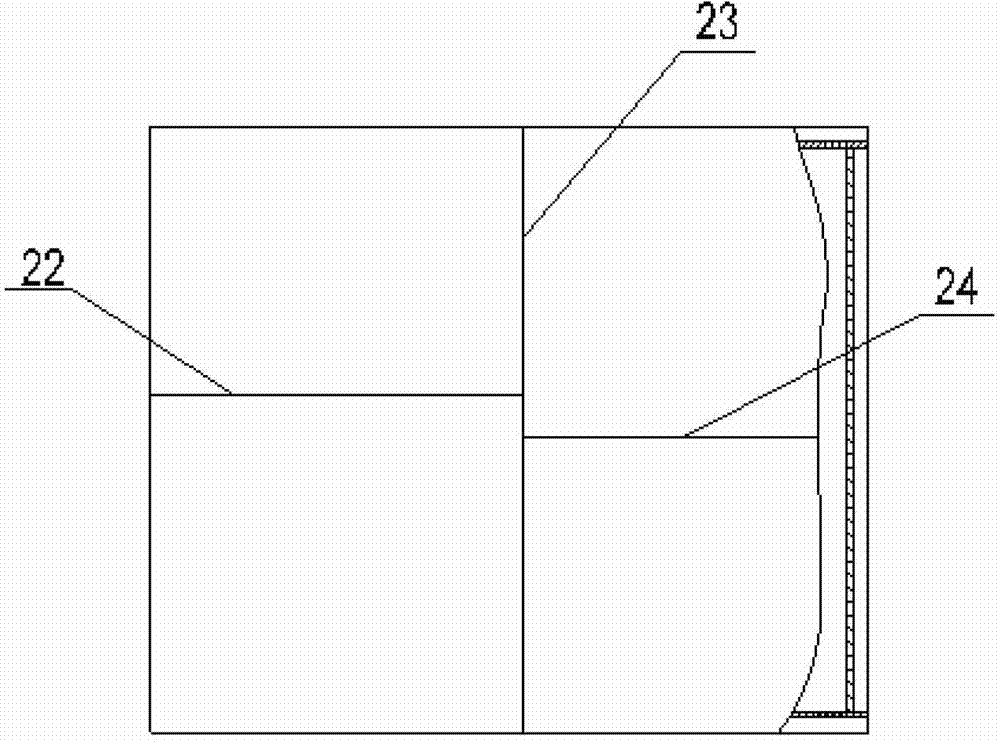

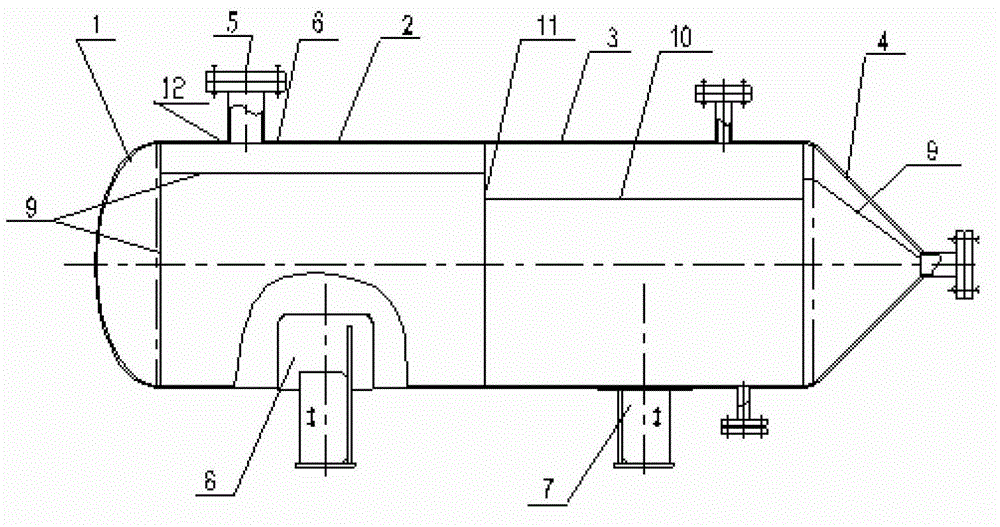

Best strain of austenitic stainless steel container welding residual stress overload reducing method

ActiveCN103160663AExtensiveVersatilityProcess efficiency improvementPrincipal stressAutomatic control

The invention provides best strain of an austenitic stainless steel container welding residual stress overload reducing method. The best strain of the austenitic stainless steel container welding residual stress overload reducing method comprises: (1) a best value exists in overload dependent variable for reducing welding residual stress, the dependent variable corresponding to first major principal stress in direction in a continuous structure zone serves as an evaluation index and overload plastic strain is in a range of 2%-5%; (2) in the process of overload, boosting speed is controlled through a variable frequency pump or an automatic control reflux valve, uploading speed is in a range of 0.2 MPa / min-0.4 MPa / min and the dependent variable is controlled through deformation measurement or strain measurement; and (3) when a container is manufactured, a tensile test is firstly performed to materials, design stress and overload stress are determined according to an actual single tensile curve of the materials and design pressure and overload pressure are calculated through a simplified method. Numerical modeling has universality and generality, evaluation stress is corroded, first tensile welding residual stress is reduced to a great extent and the residual stress after reduction is in the same level with residual stress of a cold rolling plate rear base material and residual stress after stress relief heat treatment.

Owner:北京市朝阳区特种设备检测所

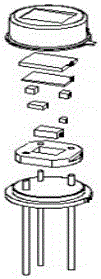

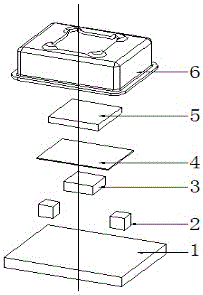

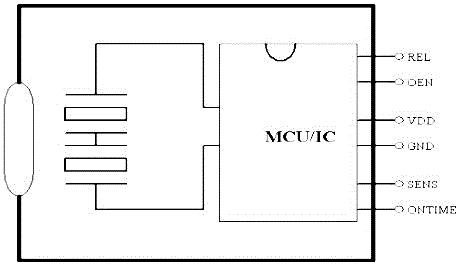

SMT intelligent pyroelectric infrared sensor

InactiveCN105698936AImprove anti-interference abilityStrong product weightSensing radiation from moving bodiesManufacturing cost reductionControl signal

The invention relates to a chip-type intelligent pyroelectric infrared sensor, which is a closed structure shell composed of a tube cap and a substrate. The upper surface of the tube cap has a window, and an infrared optical filter is embedded on the window; and the tube cap and the A receiving space is formed between the substrates, and the receiving space accommodates and encapsulates the infrared sensitive element, the supporting component and the signal processing module; the infrared sensitive element is fixed by the supporting component, and the supporting component and the signal processing module are directly fixed on the substrate. The pyroelectric infrared sensor of the present invention has the characteristics of miniaturization, intelligence, and the ability to output multiple control signals. This packaging structure is suitable for SMT automatic patch and reflow soldering processes, which is conducive to mass automatic production and improves manufacturing efficiency. Reduce manufacturing costs.

Owner:SENBA SENSING TECH CO LTD

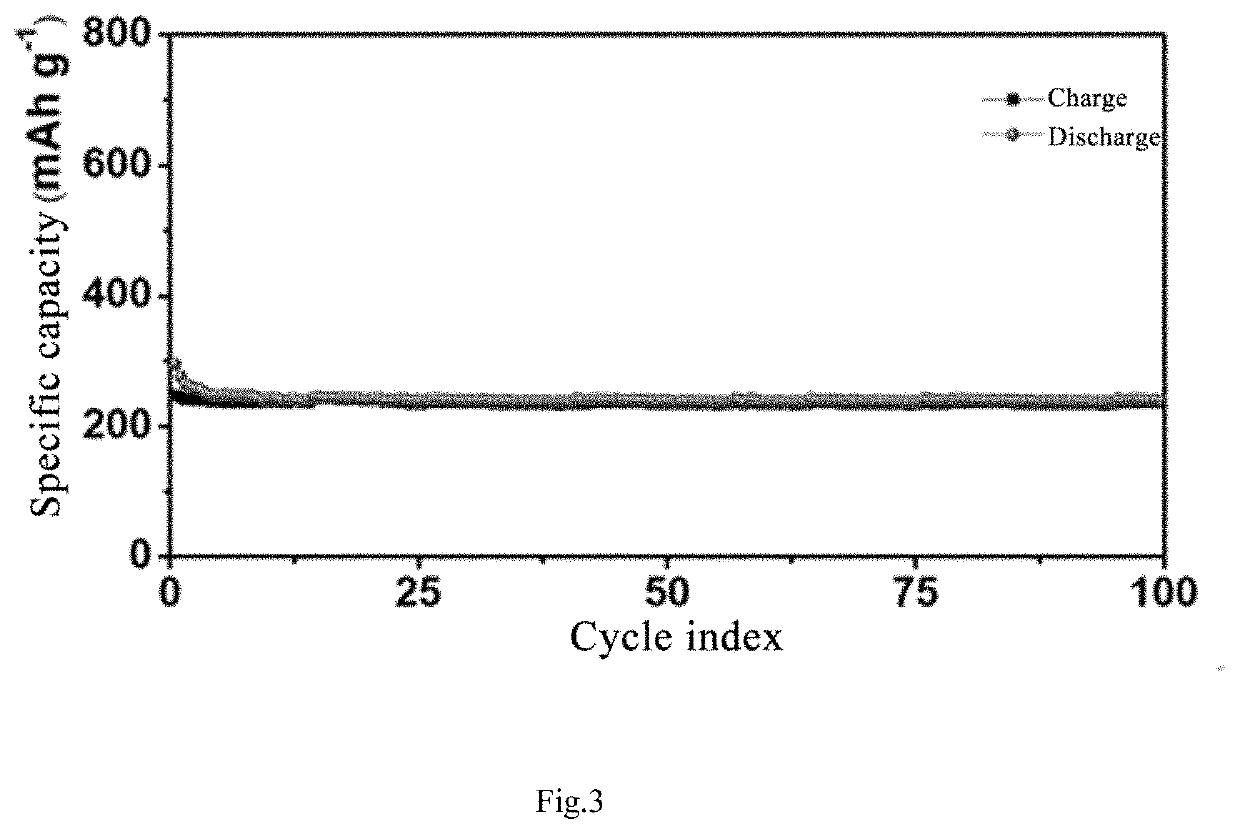

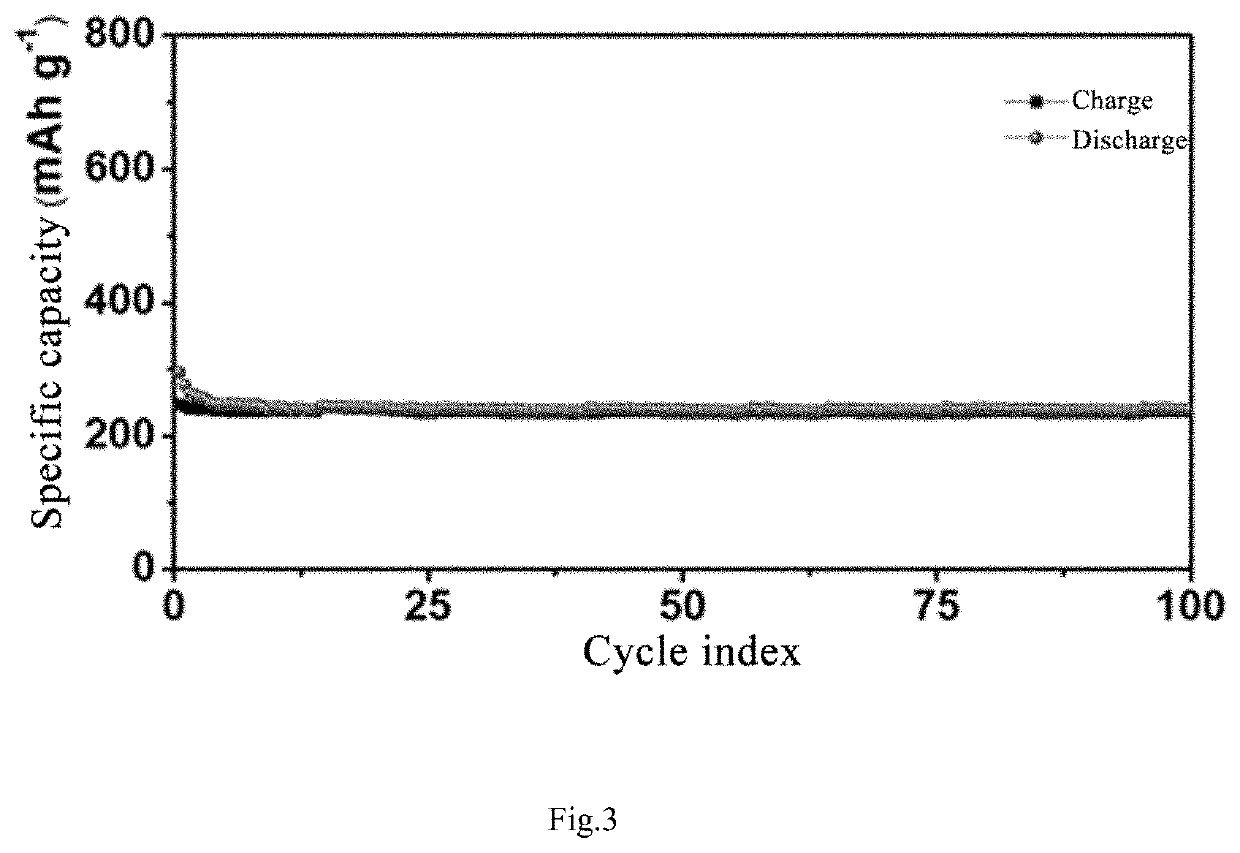

Tellurium-doped mxene composite material, and preparation method and use thereof

ActiveUS20200227745A1Increase layer spacingFacilitates ion diffusionSecondary cellsPositive electrodesIonic diffusionElectrical battery

The present invention discloses a tellurium-doped MXene composite material and a preparation method thereof, comprising the following steps: (1) adding MXene and a tellurium source into a dispersant to prepare a dispersion, and then stirring the dispersion; (2) heating the dispersion, reacting, and then cooling; (3) centrifuging the product obtained in the step (2), then washing and drying under vacuum; and (4) placing the dry product obtained in the step (3) into a corundum ark, and then transferring into a tubular furnace, heating under the protection of inert gas, retaining the temperature, and then cooling to obtain the tellurium-doped MXene composite material. The composite material prepared by the present invention can be used as a cathode of a potassium ion battery, which increases the interlamellar spacing, and optimizes an ion diffusion channel, so that the electrochemical performance of the potassium ion battery is improved.

Owner:WUYI UNIV

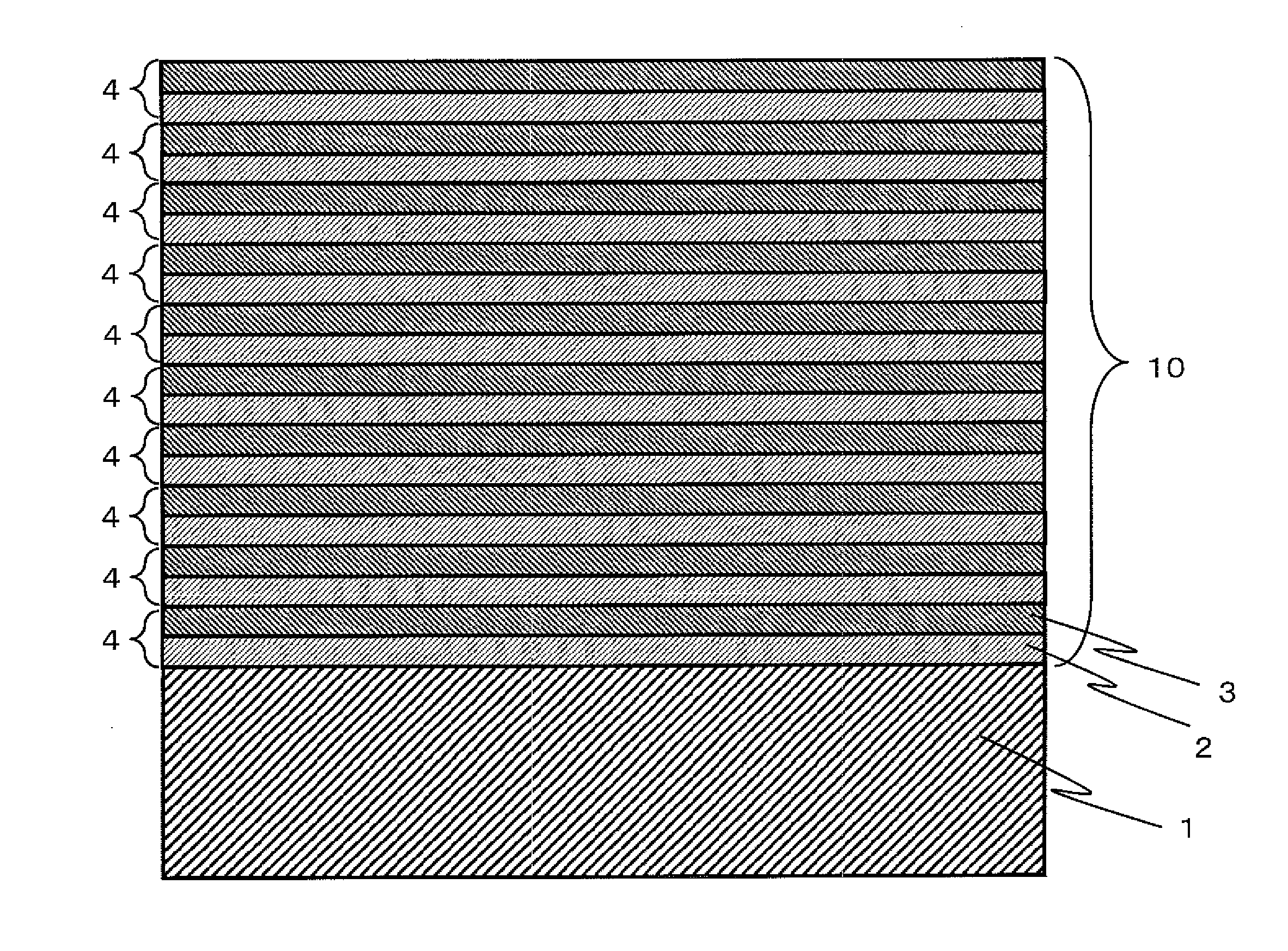

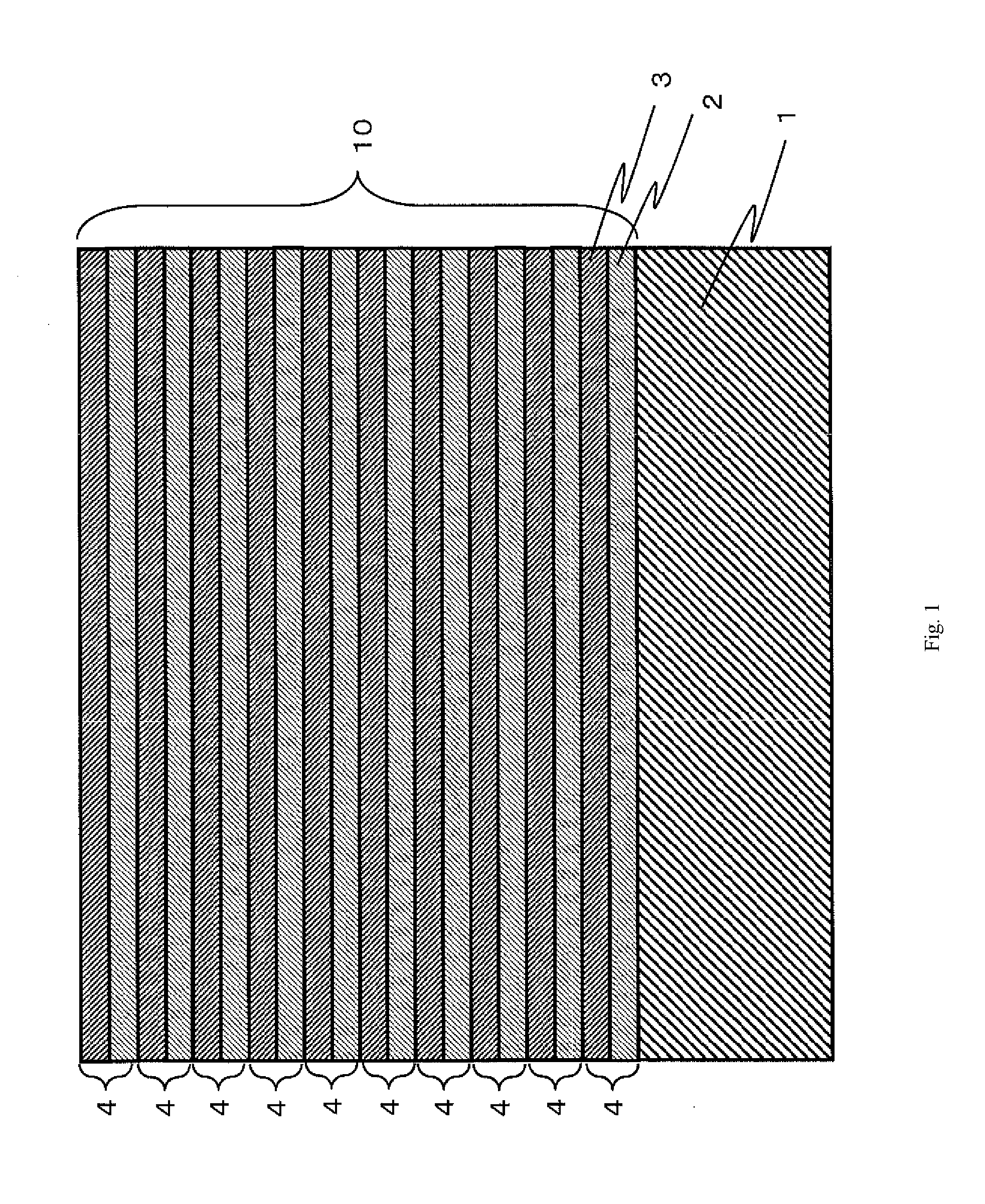

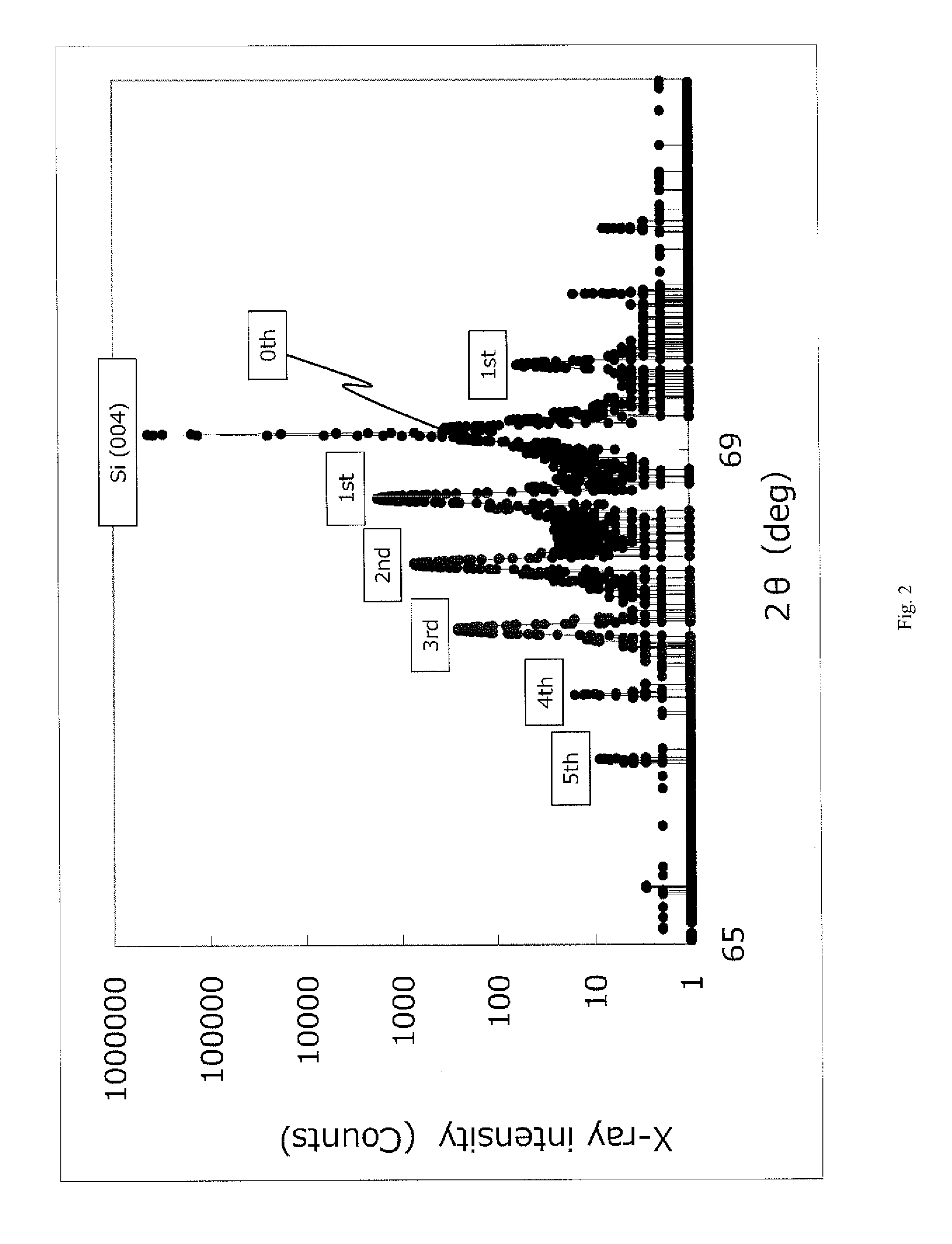

Thermoelectric device

InactiveUS20160240761A1Increase electron densityImprove power factorThermoelectric device junction materialsThin membraneCondensed matter physics

A thermoelectric device includes a semiconductor stacked thin film including a SiGe layer and a Si layer in contact with the SiGe layer. The SiGe has a Si:Ge composition ratio by atomic number ratio within a range of 85:15 to 63:37. The stacked thin film has a plurality of stacked structures each having the SiGe layer and the Si layer.

Owner:TDK CORPARATION

A kind of infrared radiation coating and preparation method thereof

ActiveCN105860611BRapid responseLow reaction temperatureAnti-corrosive paintsPotassium nitrateCordierite

The invention provides an infrared radiation paint and a preparation method thereof. The infrared radiation paint is formed by mixing a composite infrared radiation material and an organic-inorganic binder in a mass ratio of 100:(175-300), wherein the composite infrared radiation material is prepared from spinel-structure high infrared radiation powder, alundum powder, SiO2 powder, cordierite and glaze powder; and the organic-inorganic binder is formed by mixing a silicon-chromium-aluminum composite sol, silicate and potassium nitrate. The infrared radiation paint provided by the invention has favorable high-temperature stability and infrared radiation property, can be firmly bound with refractory steel and other metal matrixes, can not crack or shed after being used at the high temperature of 1000-1200 DEG C for a long time, has the advantages of favorable corrosion resistance, favorable thermal shock resistance and the like, and is suitable for popularization and application.

Owner:武汉钢铁有限公司

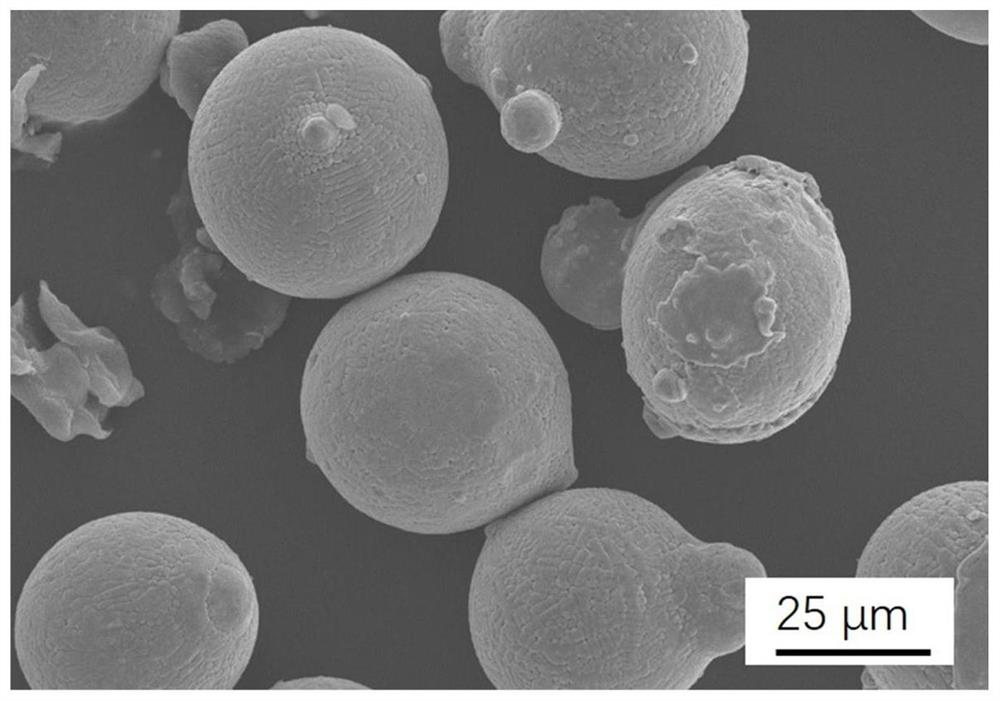

High-entropy alloy powder, high-resistance coating, as well as preparation method and application thereof

ActiveCN111763904AHigh resistivityImprove heating efficiencyMolten spray coatingHigh entropy alloysCobalt

The invention relates to high-entropy alloy powder, a high-resistance coating, as well as a preparation method and application thereof. The high-entropy alloy powder is prepared from the following components in percentage by mass: 17 to 25 percent of nickel, 14 to 25 percent of cobalt, 15 to 20 percent of chromium, 13 to 20 percent of manganese, and the balance iron. The high-entropy alloy powderis applied to the preparation of the high-resistance heating coating. According to the high-resistance coating material provided by the invention, the coating obtains a single-phase structure, the resistance of the coating is improved at the same time, the heating efficiency is improved, and the service reliability is ensured at the same time, so that the high-entropy alloy powder and the high-resistance coating have broad application prospects.

Owner:BEIJING UNIV OF TECH +1

High-strength creep-resistant high-temperature alloy and preparation method thereof

InactiveCN114737084AHigh strengthImprove creep resistanceMetal-working apparatusEfficient propulsion technologiesPhase formationSuperalloy

The invention provides a high-strength creep-resistant high-temperature alloy and a preparation method thereof, and belongs to the technical field of metallurgy. The alloy comprises the following components in percentage by mass: 10.00%-12.00% of Cr, 12.00%-18.00% of Co, 5.50%-7.50% of W, 1.50%-3.50% of Mo, 3.00%-4.20% of Al, 3.00%-4.20% of Ti, 1.00%-2.20% of Nb, 0.40%-1.50% of Ta, 0.01%-0.04% of C, 0.01%-0.04% of B, 0.09%-1.20% of Zr, less than 0.10% of Hf and the balance of Ni, and the total mass percentage of gamma'phase forming elements Al, Ti, Nb and Ta in the high-temperature alloy is as follows: 9.5% < = (Al + Ti + Nb + Ta) < = 10.3%; the mass percentage content of a gamma'phase in the high-temperature alloy is 50%-55%, and the mass ratio of Al to Ti in the high-temperature alloy is that (Al / Ti) is larger than or equal to 0.9 and smaller than or equal to 1.0. The alloy and the disc piece of the alloy can be manufactured through the method, and the disc piece of the alloy can meet the requirements of future aviation turboshaft engines for high temperature resistance, high strength and creep resistance.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A kind of high hardness al-cr-ti-v-cu light high entropy alloy and preparation method thereof

The invention provides a high-hardness Al-Cr-Ti-V-Cu light-weight high-entropy alloy and a preparation method thereof, belonging to the field of metal materials and preparation. The main components of the high-entropy alloy are composed of: Al 20-25%, Cr 20-25%, Ti 20-25%, V 20-25%, Cu 0-20%, and Cu 0-20%. The content is not 0. The phase structure of the alloy is mainly characterized by a gradual transformation from a single-phase structure to a multi-phase structure, mainly from a single BCC phase structure to a BCC+FCC phase and a small amount of HCP phase structure, and finally to FCC+HCP. phase structure. And showed high hardness above 650HV and good thermal stability. The invention also provides a preparation method of the Al-Cr-Ti-V-Cu high-entropy alloy, which adopts vacuum arc melting and direct casting to obtain an alloy ingot; the preparation process is pollution-free, low in energy consumption and low in cost.

Owner:JIANGSU UNIV

Ni-Cu-P-Ce alloy plating layer and preparation process

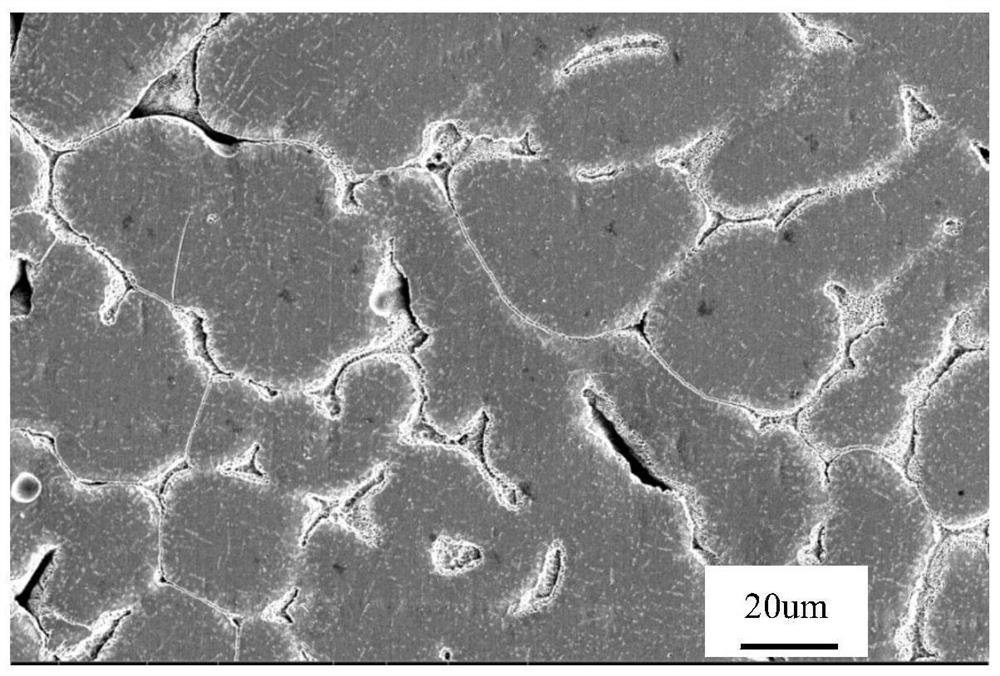

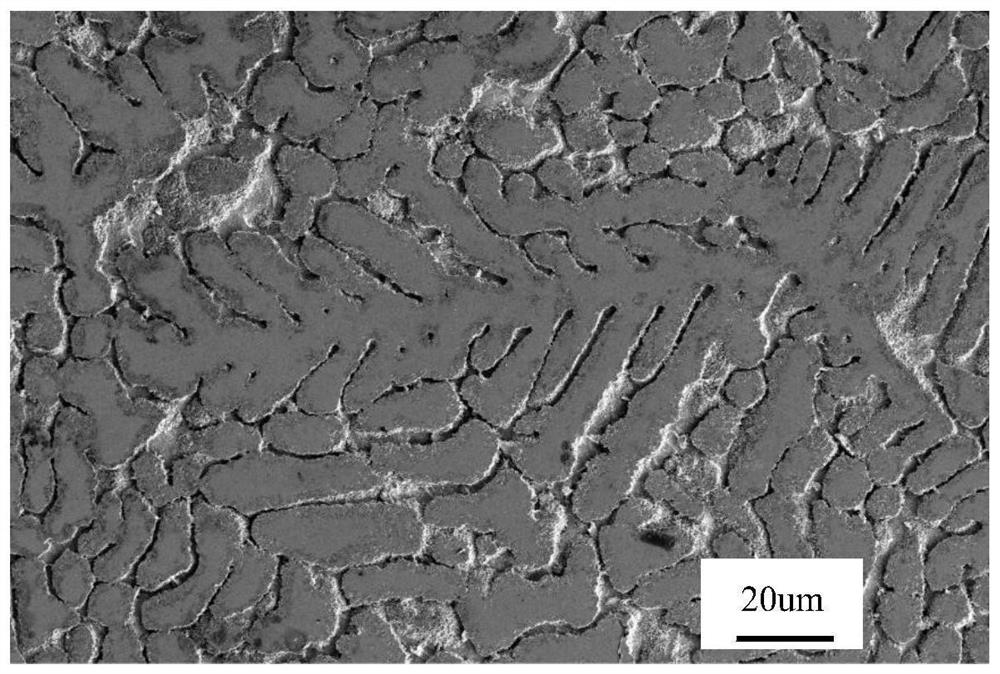

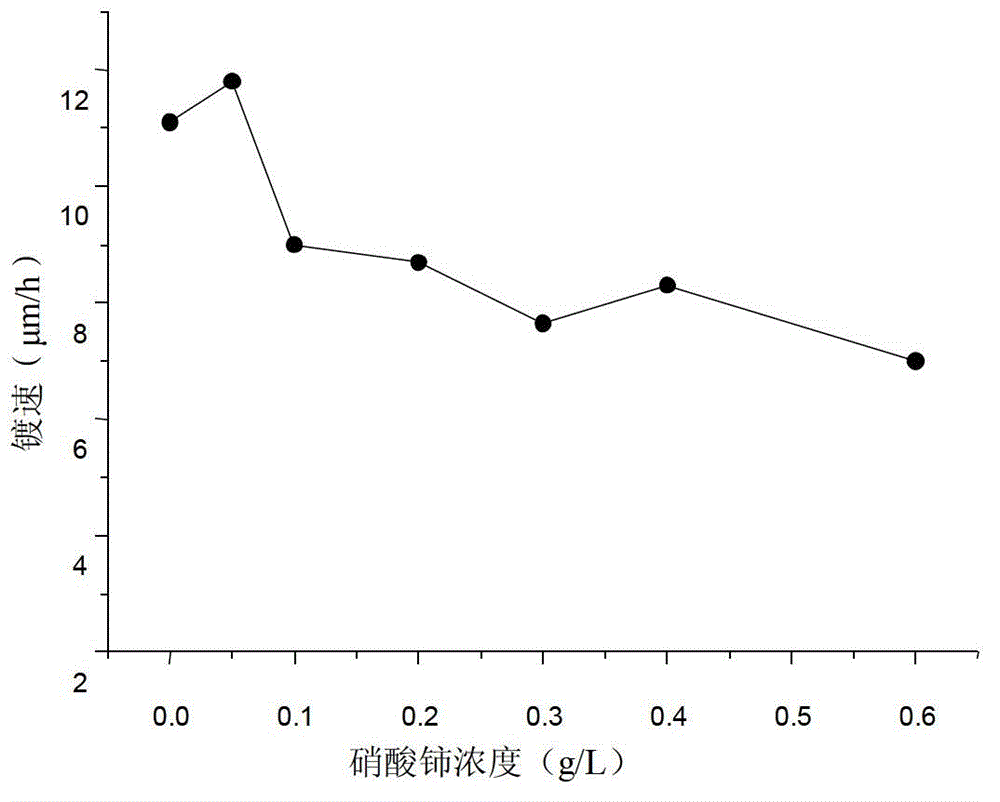

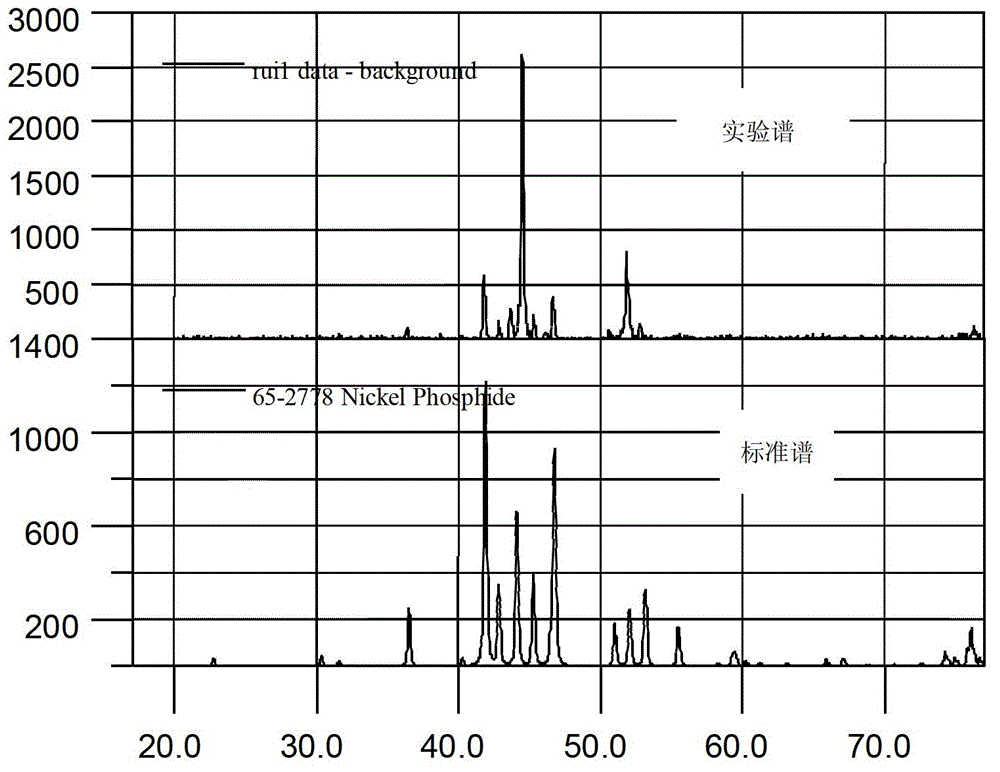

InactiveCN102994991BDense tissueTissue particles are tightly distributedLiquid/solution decomposition chemical coatingSodium acetateChemical plating

The invention relates to chemical plating on a surface of a metal material and particularly to a Ni-Cu-P-Ce alloy plating layer used for chemical plating on a surface of a low-carbon steel base material and a preparation process of the Ni-Cu-P-Ce alloy plating layer. The Ni-Cu-P-Ce alloy plating layer adopts a plating liquid composed of 35-40 g / L of nickel sulfate, 0.2-0.4 g / L of copper sulfate, 25-30 g / L of sodium hypophosphite, 8-10 g / L of sodium acetate, 25-30 g / L of trisodium citrate, 22-28 ml / L of lactic acid, 8-10 g / L of butanedioic acid, 0.2-0.4 g / L of cerium nitrate, 8 mg / L of potassium iodide, 1.5 mg / L of thiourea, 0.01 g / L of glycine and 0.2 g / L of ammonium bifluoride. For the adoption of ultrasonic chemical plating, a plating layer material formed by codeposition of Ce, Cu and Ni is obtained; and the material has increased compactness, is a microlithic texture, and is high in hardness and strong in corrosion resistance.

Owner:SHANDONG JIANZHU UNIV

High-hardness Al-Cr-Ti-V-Cu light high-entropy alloy and preparation method thereof

The invention provides a high-hardness Al-Cr-Ti-V-Cu light high-entropy alloy and a preparation method thereof, and belongs to the field of metal materials and preparation. The high-entropy alloy mainly comprises the following components in percentage by atoms: 20 to 25 percent of Al, 20 to 25 percent of Cr, 20 to 25 percent of Ti, 20 to 25 percent of V and 0 to 20 percent of Cu, wherein the content of Cu is not 0. The phase structure of the alloy is mainly characterized in that a single-phase structure is gradually converted into a multi-phase structure, a single BCC phase structure is mainly and gradually converted into a BCC+FCC phase and a small amount of HCP phase structure, and finally the structure is converted into an FCC+HCP phase structure. The high hardness of 650 HV or above and good thermal stability are shown. The invention further provides a preparation method of the Al-Cr-Ti-V-Cu high-entropy alloy. Vacuum arc melting and direct casting are performed to obtain an alloy ingot; and the preparation process is pollution-free, low in energy consumption and low in cost.

Owner:JIANGSU UNIV

Ferrite-based high-temperature infrared radiation material and preparation method thereof

The invention relates to a ferrite-based high-temperature infrared radiation material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps of: evenly mixing Fe2O3 fine powder, MnO2 fine powder, CuO fine powder and Co2O3 fine powder, wherein the mass ratio of Fe2O3 to MnO2 to CuO to Co2O3 is x: (8-x):1:1 (x is larger than or equal to 1 and less than or equal to 7); filling the mixture into a sagger and then putting the sagger into a microwave oven, heating to 900-1180 DEG C, and carrying out heat preservation for 30-60 minutes to prepare a ferrite blackening agent; and evenly mixing one of cordierite fine powder, mullite fine powder and spodumene fine power with the ferrite blackening agent in a mass ratio of (1-4):1, filling evenly mixed prefabricate in the sagger and then putting the sagger into the microwave oven, heating to 1000 DEG C-1200 DEG C, and carrying out heat preservation for 30-60 minutues to obtain the ferrite-based high-temperature infrared radiation material. The method has the characteristics of short production period and low energy consumption; and the prepared ferrite-based high-temperature infrared radiation material is small in expansion coefficient and excellent in infrared radiation performance in middle-short wavebands.

Owner:湖北赛格瑞新能源科技有限公司

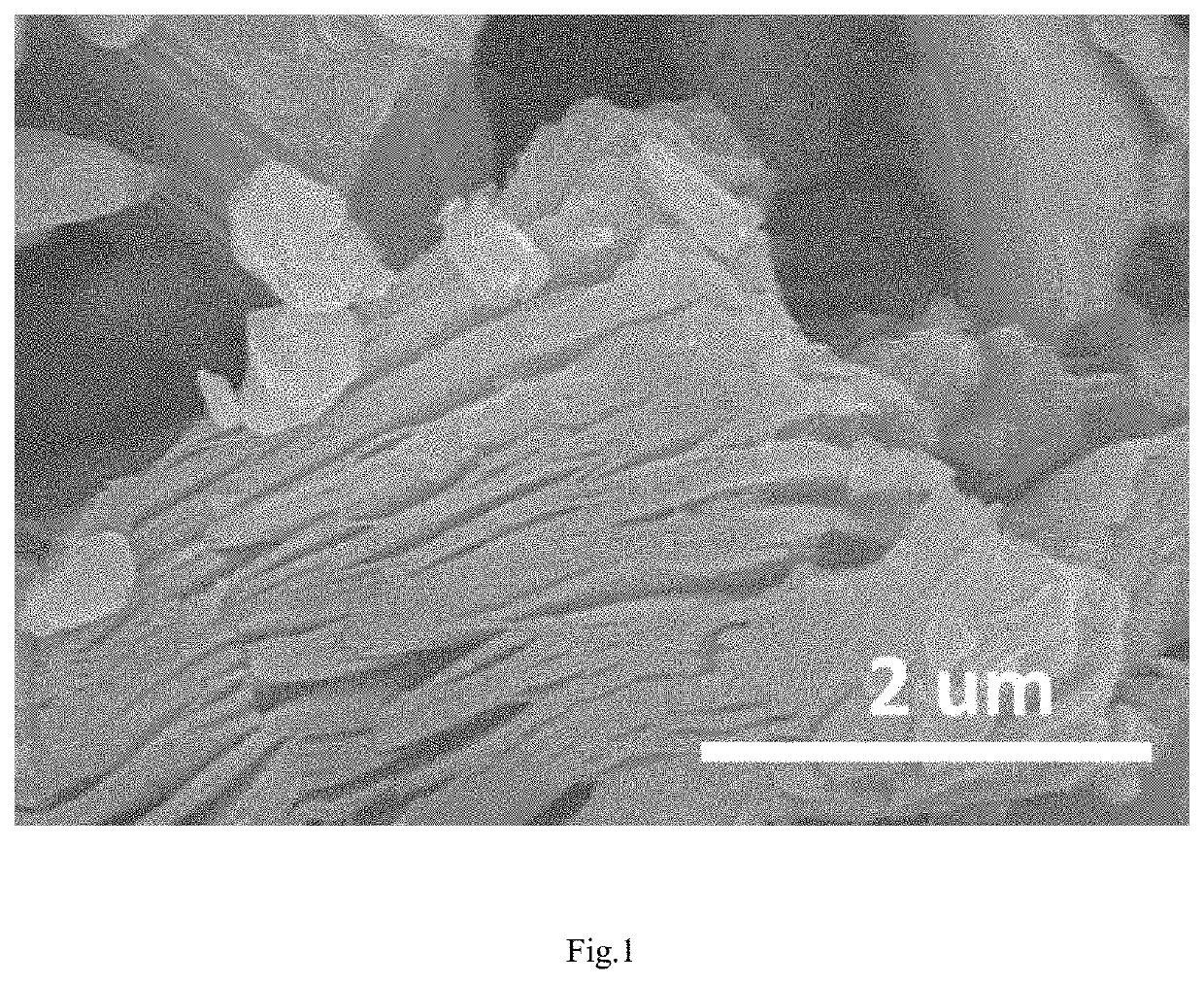

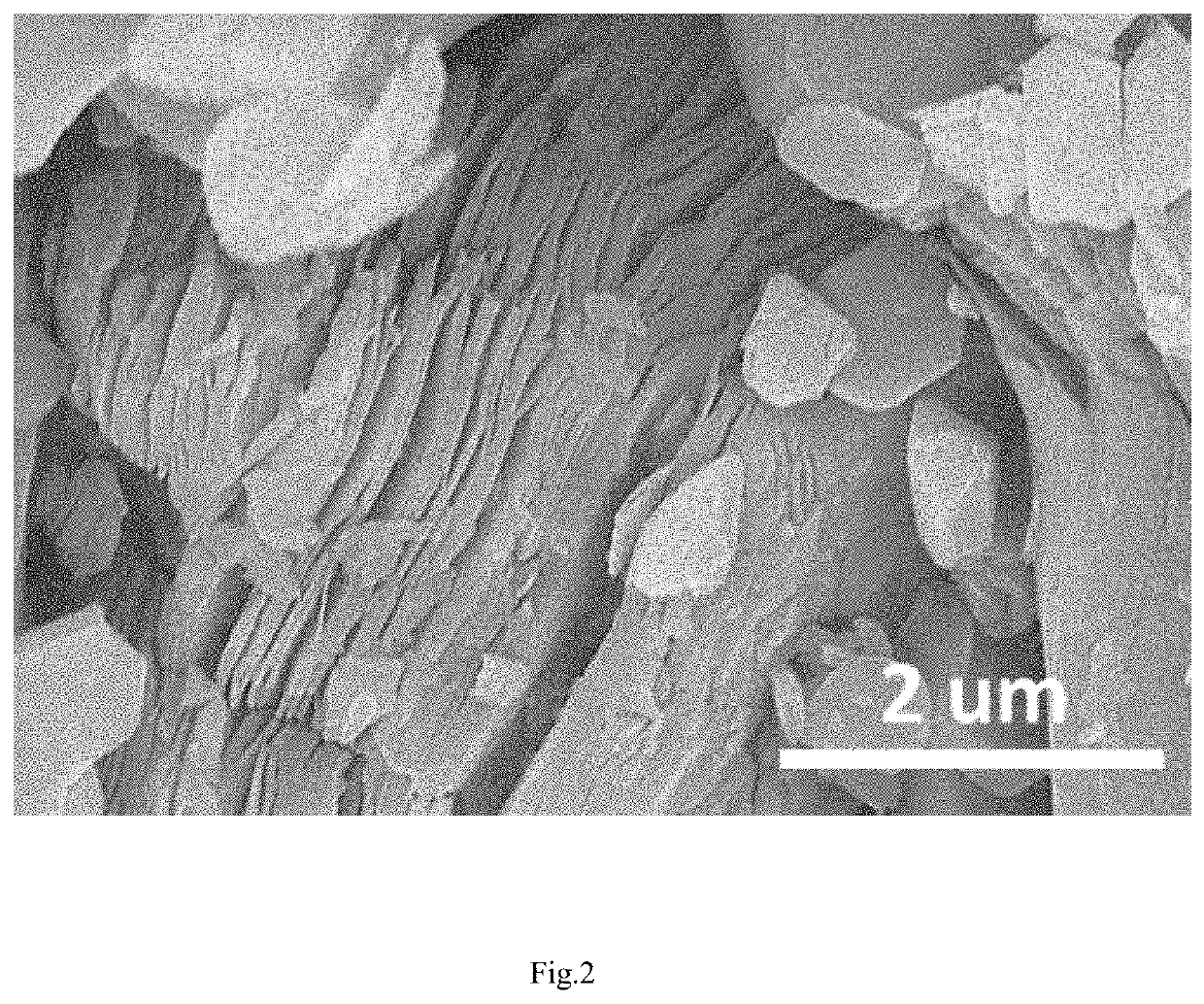

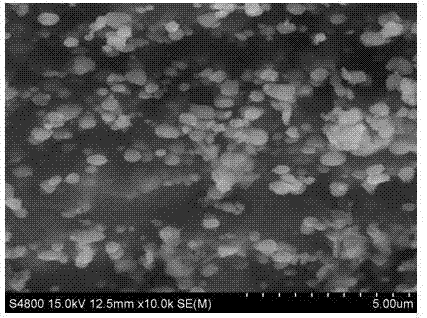

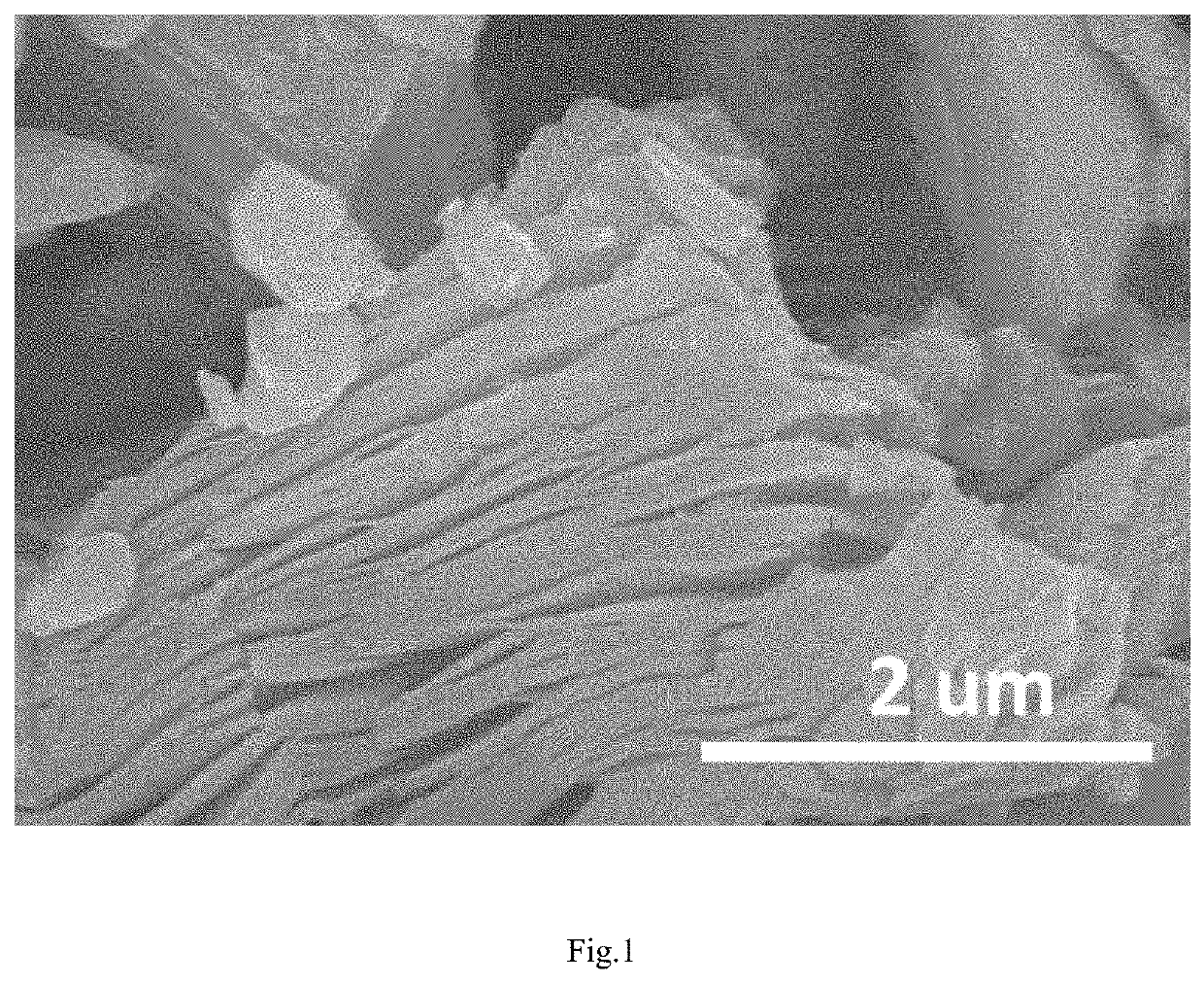

A nanoscale powder mg 2 The preparation method of ni compound

A kind of nanoscale powder Mg 2 The preparation method of Ni compound belongs to the field of material preparation technology, and the magnesium-nickel alloy is processed by the severe plastic deformation technology, so that the microstructure is fully refined, and the Mg 2 The size of the Ni phase is reduced to the nanoscale, and then the magnesium in the matrix is corroded, and the corrosion product is filtered and dried to obtain nanoscale powder Mg with uniform particle size 2 Ni. The process of the present invention is simple and reliable, and the cost is low, and the obtained nano-scale powder Mg 2 Ni has a size comparable to that of the nodular method, and Mg 2 Ni crystals retain a large dislocation density and lattice distortion, which greatly improves its hydrogen storage performance.

Owner:YANGZHOU UNIV

Tellurium-doped MXene composite material, and preparation method and use thereof

ActiveUS10847798B2Easy to operateLarge lattice distortionSecondary cellsPositive electrodesElectrical batteryTube furnace

Owner:WUYI UNIV

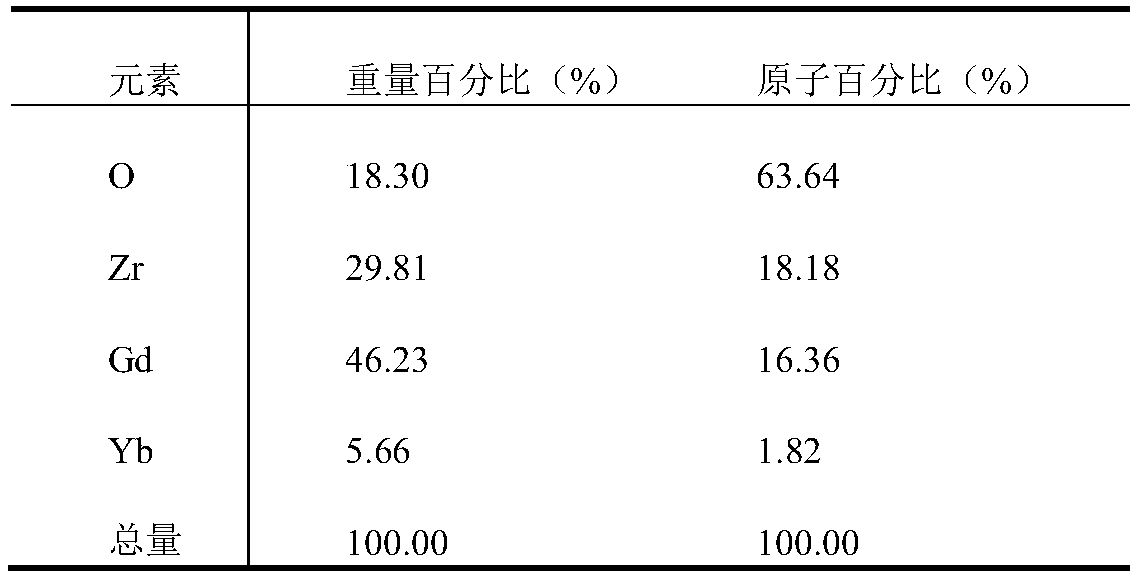

Rare earth oxide doped gadolinium zirconate powder for plasma physical vapor deposition and preparation method thereof

ActiveCN108640692BLarge lattice distortionStrong scattering abilityMolten spray coatingZirconateSlurry

Owner:BEIHANG UNIV

Best strain of austenitic stainless steel container welding residual stress overload reducing method

ActiveCN103160663BVersatilityGuaranteed reliabilityProcess efficiency improvementPrincipal stressAutomatic control

The invention provides best strain of an austenitic stainless steel container welding residual stress overload reducing method. The best strain of the austenitic stainless steel container welding residual stress overload reducing method comprises: (1) a best value exists in overload dependent variable for reducing welding residual stress, the dependent variable corresponding to first major principal stress in direction in a continuous structure zone serves as an evaluation index and overload plastic strain is in a range of 2%-5%; (2) in the process of overload, boosting speed is controlled through a variable frequency pump or an automatic control reflux valve, uploading speed is in a range of 0.2 MPa / min-0.4 MPa / min and the dependent variable is controlled through deformation measurement or strain measurement; and (3) when a container is manufactured, a tensile test is firstly performed to materials, design stress and overload stress are determined according to an actual single tensile curve of the materials and design pressure and overload pressure are calculated through a simplified method. Numerical modeling has universality and generality, evaluation stress is corroded, first tensile welding residual stress is reduced to a great extent and the residual stress after reduction is in the same level with residual stress of a cold rolling plate rear base material and residual stress after stress relief heat treatment.

Owner:北京市朝阳区特种设备检测所

A method for preparing oxide dispersion strengthened iron-based alloy

The invention discloses a method for preparing an oxide dispersion strengthened iron-base alloy, and belongs to the technical field of metal dispersion strengthening. The method comprises the following steps of: taking iron blocks, a Fe-Mn alloy and an Ni-Al alloy as raw materials, performing a vacuum smelting and electroslag smelting duplex process to obtain a pure intermediate alloy cast ingot; crushing the intermediate alloy cast ingot in a crusher with protective atmosphere to obtain intermediate alloy powder; and performing high-energy ball-milling on intermediate alloy powder, matrix powder and oxide powder to obtain the oxide dispersion strengthened iron-base alloy. Oxide dispersion strengthened iron-base alloy powder is subjected to hot isostatic pressing treatment and thermal treatment to obtain the final oxide dispersion strengthened iron-base alloy. The method adopts the duplex smelting process, so that content of oxygen and nonmetal impurities in cast ingot is effectively reduced; the alloyed intermediate alloy prevents oxidization of an element Mn, ball-milling time can be shortened and energy consumption is reduced. The prepared oxide dispersion strengthened iron-base alloy is co-strengthened by a L21 type Ni2AlMn intermetallic compound and an oxide dispersed phase, so that the strengthening effect is remarkable.

Owner:UNIV OF SCI & TECH BEIJING

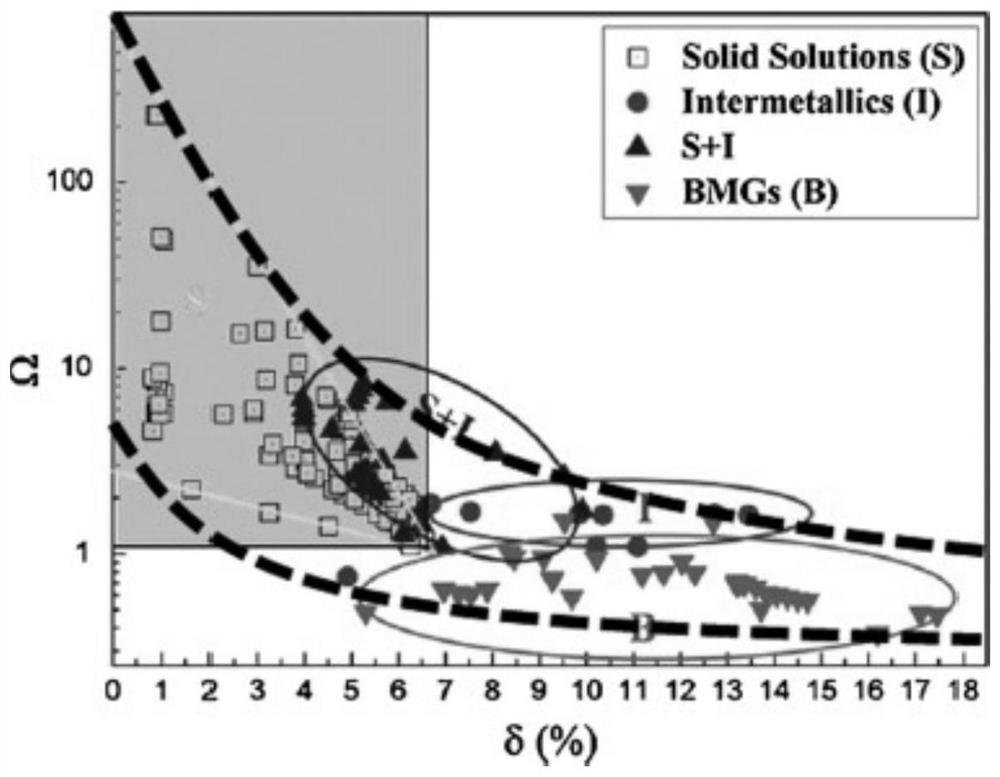

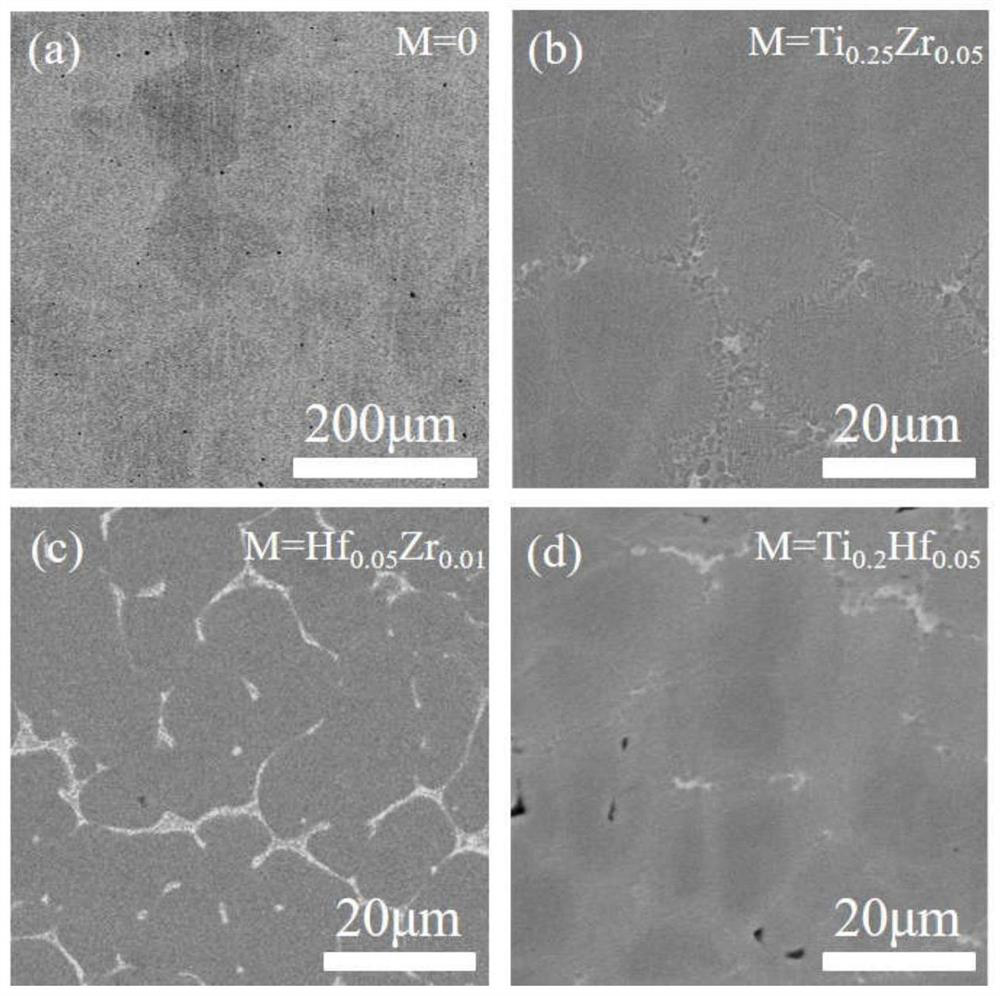

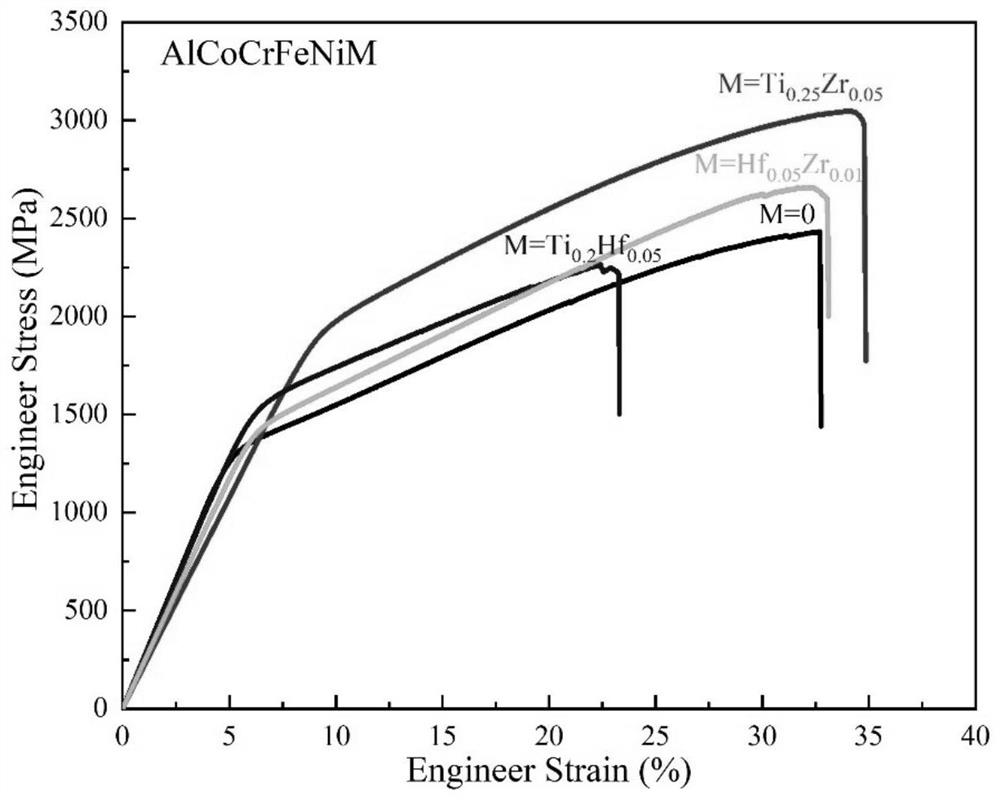

A kind of high-entropy alloy reinforced and toughened by multi-element doping and its preparation method

ActiveCN111893364BStrong solid solution strengthening effectImprove the effect of solid solution strengtheningHigh entropy alloysUltimate tensile strength

The invention belongs to the field of high-entropy alloys, and in particular relates to a high-entropy alloy reinforced and toughened by multi-element doping and a preparation method thereof. The high-entropy alloy composition includes Al, Co, Cr, Fe, Ni, and M, and the atomic percentages of each element are: Al is 16%-22%, Co is 16%-22%, and Cr is 16%-22%. , Fe is 16%-22%, Ni is 16%-22%, M is 1%-8%; the Ω of the high-entropy alloy is 1.1-1.5, and the δ is 6.2-6.8; the M element is selected from Zr , Ti, Hf at least 2 kinds. The preparation method is as follows: put the high-purity metal in a vacuum electric arc melting furnace, and repeatedly smelt it for more than four times under the protection of an inert atmosphere. The invention uses the concept of multi-element doping, so that the strength and toughness of the high-entropy alloy of the system are significantly improved, and the density is also reduced, thereby increasing the specific strength of the alloy.

Owner:CENT SOUTH UNIV

A method for regulating the properties of cocrfenicu high-entropy alloys

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Production method of graphitized free-machining steel

The invention relates to a method for producing graphitized free-machining steel from intermediate-carbon manganese-silicon steel, intermediate-carbon manganese-silicon-aluminum steel and the like. The method comprises the following steps: heating casting blanks; maintaining the temperature; cooling to 1050-1150 DEG C; roughly rolling: controlling the reduction percentage of each gate to be 20-40%; cooling to 850-1000 DEG C; carrying out precision rolling according to 4-6 gates; cooling in air; quickly cooling in water to room temperature; heating the precision rolling plate and maintaining the temperature; and cooling in air or cooling in a furnace to room temperature. By controlling the state of C atoms in steel and C content of austenite before tempering based on a process route of low-temperature rolling, relaxation and phase change, quenching and graphitization tempering, the invention converts all C atoms in the steel into graphite in a short time (5h). In the graphitized free-machining steel produced by the method, graphite grains in the organization are small in size and are uniform in distribution.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com