Preparation method for high-entropy alloy coating

A high-entropy alloy and coating technology, applied in metal material coating process, coating, heating inorganic powder coating and other directions, can solve the problems of slag inclusion in pores, uneven formation of coating structure, and large thermal deformation of the substrate. , to achieve excellent wear resistance, hinder dislocation slip, and increase strain energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Select Q235 steel as the base material, including the following steps:

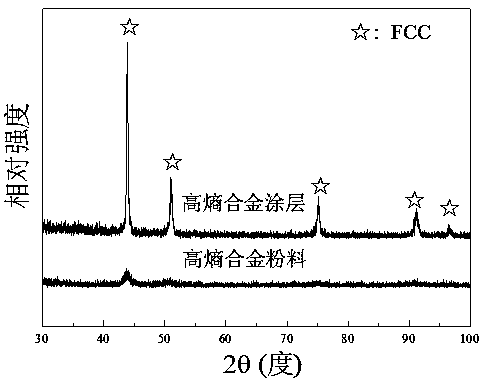

[0034] Step (1): Coating powder preparation: Co, Cr, Fe and Ni metal powders with a particle size of 75 μm and a purity of not less than 99.5% by mass are mixed in a molar ratio of 1:1:1:1 to obtain Coating powder.

[0035] Step (2): Put the coating powder in a planetary ball mill, wherein, the rotating speed: 200-400r / min, the ball-material ratio: 10:1-20:1, the time: 180-220h; the obtained particle size is 5- 15 μm high entropy alloy powder.

[0036] Step (3): Pretreatment of the Q235 metal substrate: Cut the surface of the substrate with a milling machine to remove the oxide layer until the metallic luster is exposed and the surface of the substrate is smooth; then clean the surface of the substrate with absolute ethanol, clean After finishing, rinse with distilled water and dry for later use.

[0037] Step (4): Pre-place the high-entropy alloy powder prepared in step (2) on the surface of th...

Embodiment 2

[0045] Select Q235 steel as the base material, including the following steps:

[0046] Step (1): Prepare coating base material: Co, Cr, Fe and Ni metal powders with a particle size of 75 μm and a purity of not less than 99.5% by mass, and mix them in a molar ratio of 1:1:1:1 to obtain Coating powder.

[0047] Step (2): Put the coating powder in a planetary ball mill, wherein: the rotating speed is 200-400r / min, the ball-to-material ratio is 10:1-20:1, and the time is 180-220h; obtain a high particle size of 5-15μm Entropy alloy powder.

[0048] Step (3): Pretreatment of the Q235 metal substrate: Cut the surface of the substrate with a milling machine to remove the oxide layer until the metallic luster is exposed and the surface of the substrate is smooth; then clean the surface of the substrate with absolute ethanol, clean After finishing, rinse with distilled water and dry for later use.

[0049] Step (4): Pre-place the high-entropy alloy powder prepared in step (2) on the...

Embodiment 3

[0056] Table 1 Mole percentage of Co, Cr, Fe, Ni

[0057]

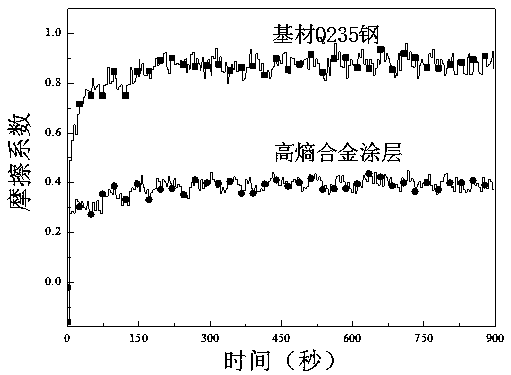

[0058] ; According to the atomic percentage distribution material in Table 1, the coating powder is prepared; other operations are the same as in Example 1. The appearance of the prepared high-entropy alloy coating is consistent with that of Example 1, the hardness is 440-460HV, and the friction coefficient is about 0.35-0.42.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com