Rare earth catalytic permeation QPQ composition and method for manufacturing high-speed cutting tool by QPQ process

A technology of high-speed cutting and rare earth compounds, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of small thickness, low hardness and low grain size of the nitrided layer, and achieve The effect of shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

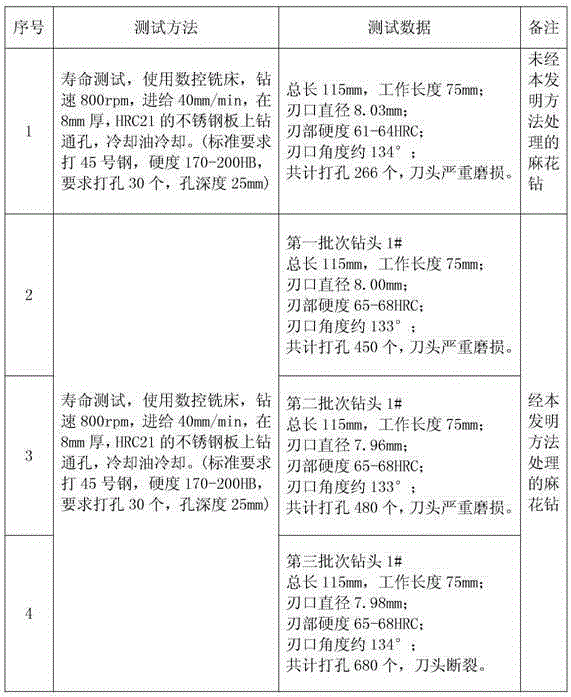

Examples

Embodiment Construction

[0041] The present invention will be further described below.

[0042] The rare earth catalyzed QPQ composition of the present invention contains QPQ base salt, and the molten QPQ base salt contains CNO - , the composition contains a rare earth compound as an infiltration agent, the rare earth compound is 0.0001-10% of the weight of the QPQ base salt, the rare earth compound is a solid mixture of La carbonate and Ce carbonate, and the QPQ combination Contain the ion of following weight percentage in the thing:

[0043] Na + =10~40wt%,

[0044] K + =8~25wt%,

[0045] CO 3 2- =15~45wt%,

[0046] Cl - =10~20%,

[0047] CNO - =10~42%,

[0048] La 3+ =0.0001~10wt%,

[0049] Ce 3+ =0.0001~10wt%,

[0050] The sum of the weight percentages of each ion is 100%.

[0051] Specifically, the weight ratio of La carbonate to Ce carbonate is 1:3˜3:1.

[0052] In order to obtain better technical effect, the ion of following percentage by weight is included in the molten rare e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com