Method of regulating performance of CoCrFeNiCu high-entropy alloy

A high-entropy alloy and performance technology, which is applied in the field of regulating the microstructure and mechanical properties of CoCrFeNiCu high-entropy alloys, can solve the problems of general alloy performance, long processing cycle, and complicated operation, and achieve high safety, easy operation, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

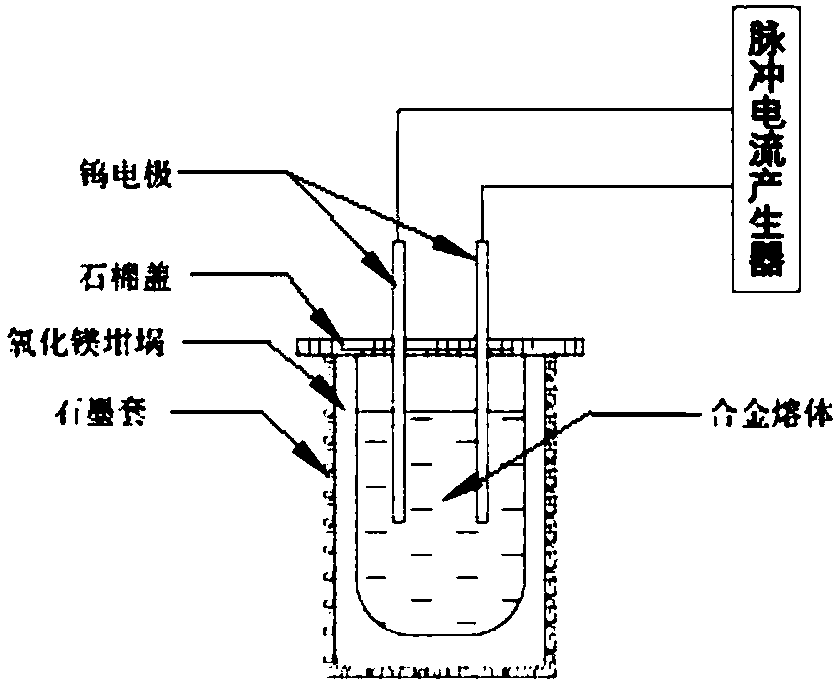

[0030] Such as figure 1 as shown,

[0031] In a specific embodiment of the present invention, a method for regulating and controlling the properties of a CoCrFeNiCu high-entropy alloy, the specific steps include:

[0032] Material preparation: Prepare Co, Cr, Fe, Ni, Cu elemental pure metal raw materials with a purity greater than 99.8%, and cut larger blocks, plates, strips, bars, etc. into smaller blocks and bars that are easy to use material etc. Weigh raw materials Co, Cr, Fe, Ni, Cu in equimolar ratio. The molar ratio of any two elements of the raw materials is 1:1. Weigh Co=295.55g; Cr=260.50g; Fe=279.78g; Ni=294.05g; Cu=318.37g.

[0033] Filling: Put the weighed raw materials Co, Cr, Fe, Ni, Cu into the magnesia crucible in order of melting point from low to high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com