A kind of infrared radiation coating and preparation method thereof

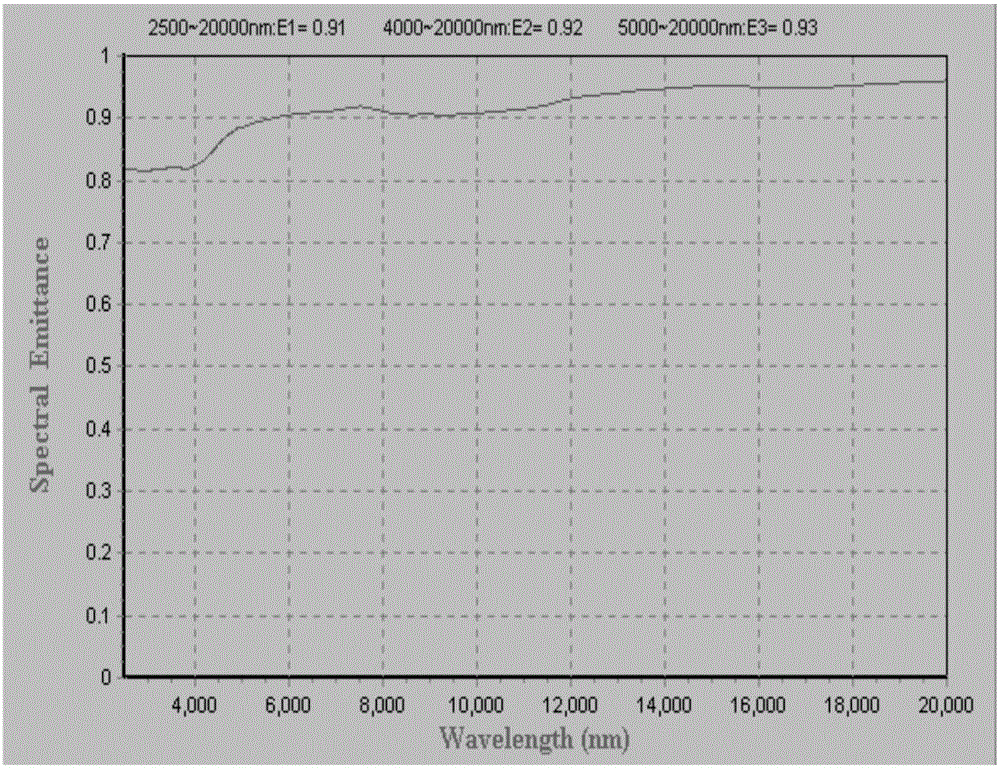

An infrared radiation coating and infrared radiation technology, applied in the field of energy-saving materials, can solve the problems of unsatisfactory metal matrix bonding ability, poor adhesion between coating and matrix, unstable coating emissivity, etc., achieving large lattice distortion and short holding time. , the effect of stable infrared emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An infrared radiation coating, the preparation steps are as follows:

[0036] 1) Spinel structure infrared radiation powder

[0037] Weigh each raw material according to the proportion, and each raw material and its mass percentage are: FeTiO 3 60%, Fe 2 O 3 7.5%、MnO 2 7.5%, Co 2 O 3 7.5%、CuO 7.5%、Cr 2 O 3 10%, mix the weighed raw materials and disperse them in absolute ethanol, rotating and wet mixing for no less than 12 hours, and then dry the mixed wet material to obtain a mixture; place the mixture in a graphite reactor and Put it into a high-current pulse reaction synthesis device, apply pulse current directly to the graphite reactor under vacuum (≤10Pa), heat it to 1150℃ at a heating rate of 400℃ / min, keep it for 5 minutes, and get spinel after natural cooling Synthetic powder with stone structure; put the synthetic powder in a vacuum ball milling tank, the grinding medium is alumina, the ball-to-battery ratio is 30:1, and the spinel with a particle size of ≤2μm i...

Embodiment 2

[0042] An infrared radiation coating, the preparation steps are as follows:

[0043] 1) Spinel structure infrared radiation powder

[0044] Weigh each raw material according to the proportion, and each raw material and its mass percentage are: FeTiO 3 60%, Fe 2 O 3 7.5%、MnO 2 7.5%, Co 2 O 3 7.5%、CuO 7.5%、Cr 2 O 3 10%, mix the weighed raw materials and disperse them in absolute ethanol, rotating and wet mixing for no less than 12 hours, and then dry the mixed wet material to obtain a mixture; place the mixture in a graphite reactor and Put it into a high-current pulse reaction synthesis device, apply pulse current directly to the graphite reactor under vacuum (≤10Pa), heat it to 1050°C at a heating rate of 200°C / min, keep it for 15 minutes, and cool down naturally to obtain spinel Synthetic powder with stone structure; put the synthetic powder in a vacuum ball milling tank, the grinding medium is alumina, the ball-to-battery ratio is 30:1, ball milled at 300r / min for 24h to obt...

Embodiment 3

[0049] An infrared radiation coating, the preparation steps are as follows:

[0050] 1) Spinel structure infrared radiation powder

[0051] Weigh each raw material according to the proportion, and each raw material and its mass percentage are: FeTiO 3 42%, Fe 2 O 3 10%, MnO 2 10%, Co 2 O 3 10%, CuO 10%, Cr 2 O 3 18%, mix the weighed raw materials and disperse them in absolute ethanol, rotating and wet mixing for no less than 12 hours, and then drying the mixed wet material to obtain a mixture; place the mixture in a graphite reactor and Put it into a high-current pulse reaction synthesis device, apply pulse current directly to the graphite reactor under vacuum (≤10Pa), heat it to 1200°C at a heating rate of 400°C / min, keep it for 5 minutes, and cool down naturally to obtain spinel Synthetic powder with stone structure; place the synthetic powder in a vacuum ball milling tank, the grinding medium is alumina, the ball-to-battery ratio is 30:1, and the spinel with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com