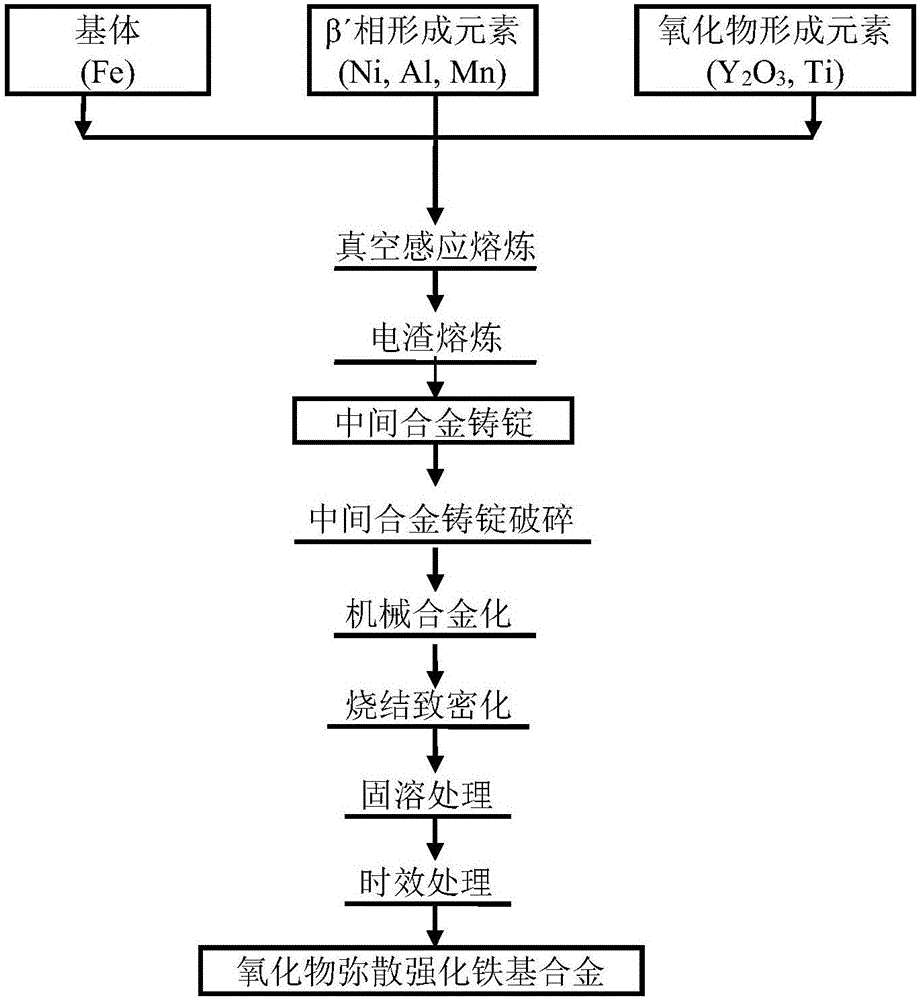

Method for preparing oxide dispersion strengthened iron-base alloy

A technology of dispersion strengthening and iron-based alloys, which is applied in the field of metal dispersion strengthening, can solve the problems of not being able to effectively control the composition of intermetallic compounds, reduce the high-temperature mechanical properties of materials, and limit the improvement of strengthening effects, so as to achieve significant strengthening effects and shorten ball milling Time, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: 35wt.% Fe powder + master alloy powder + 0.3wt.% nano Y 2 o 3 Powder Preparation 5Ni-1Al-3Mn-0.3Y 2 o 3 -0.3Ti-Balanced Fe Oxide Dispersion Strengthened Iron-Based Alloy

[0015] Iron block, Fe-Mn alloy, Ni-Al alloy and Fe-Ti alloy are used as raw materials, and the purity of each raw material is greater than 99.9%. Metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides. The pretreatment time is 30 minutes. After washing with alcohol, they are dried in an oven at 60°C for 90 minutes. The intermediate alloy is smelted in a vacuum induction furnace. During the smelting process, a CaO ceramic crucible is used, and the power is increased after the furnace material is melted, so that the temperature of the molten pool rises to 1600 ° C, and the temperature is kept for 30 minutes. The liquid is cast into an intermediate alloy ingot; the vacuum induction melted ingot is electroslag smelted in an inert atmosphere....

Embodiment 2

[0016] Example 2: 40wt.% Fe powder + master alloy powder + 0.3wt.% nano Y 2 o 3 Powder Preparation 5Ni-1Al-3Mn-0.3Y 2 o 3 -0.3Ti-Balanced Fe Oxide Dispersion Strengthened Iron-Based Alloy

[0017] Iron block, Fe-Mn alloy and Ni-Al alloy are used as raw materials, and the purity of each raw material is greater than 99.9%. Metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides. The pretreatment time is 30 minutes. After washing with alcohol, they are dried in an oven at 70°C for 60 minutes; the master alloy is smelted in a vacuum induction furnace. CaO ceramic crucible is used in the smelting process, and the power is increased after the furnace material is melted, so that the temperature of the molten pool rises to 1600 ° C, and the temperature is kept for 30 minutes. After that, the temperature is lowered, filled with argon, and the molten steel is poured into an intermediate alloy ingot; The melted ingot is electroslag smelt...

Embodiment 3

[0018] Example 3: 50wt.% Fe powder + master alloy powder + 0.3wt.% nano Y 2 o 3 Powder Preparation 5Ni-1Al-3Mn-0.3Y 2 o 3 -0.3Ti-Balanced Fe Oxide Dispersion Strengthened Iron-Based Alloy

[0019] Iron block, Fe-Mn alloy and Ni-Al alloy are used as raw materials, and the purity of each raw material is greater than 99.9%. Metal raw materials are pretreated in 5vol.% hydrochloric acid aqueous solution to remove surface oxides. The pretreatment time is 30 minutes. After washing with alcohol, they are dried in an oven at 75°C for 45 minutes; the master alloy is smelted in a vacuum induction furnace. CaO ceramic crucible is used in the smelting process, and the power is increased after the furnace material is melted, so that the temperature of the molten pool rises to 160°C, and the temperature is kept for 30 minutes, then the temperature is lowered, filled with argon, and the molten steel is poured into an intermediate alloy ingot; vacuum induction The melted ingot is electros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com