High-entropy alloy powder, high-resistance coating, as well as preparation method and application thereof

A high-entropy alloy, high-resistance technology, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of insufficient reliability, low resistance of resistance wire materials, low heating efficiency, etc., to achieve heating efficiency and The effect of high reliability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The chemical composition and mass percentage of the alloy material in this embodiment are: nickel: 17%, cobalt: 14%, chromium: 20%, manganese: 14%, iron: balance, and unavoidable impurities. Spraying process parameters are: current: 550A, argon gas flow rate: 30L / min, hydrogen gas flow rate: 10L / min, powder feeding rate: 58g / min, spraying distance: 130mm.

Embodiment 2

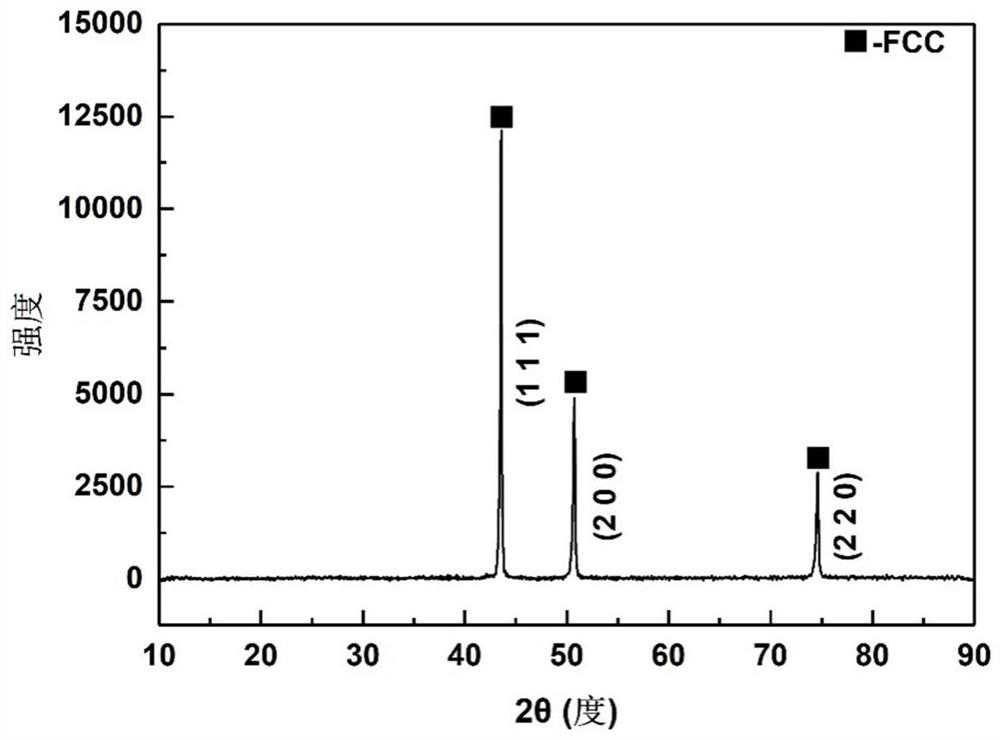

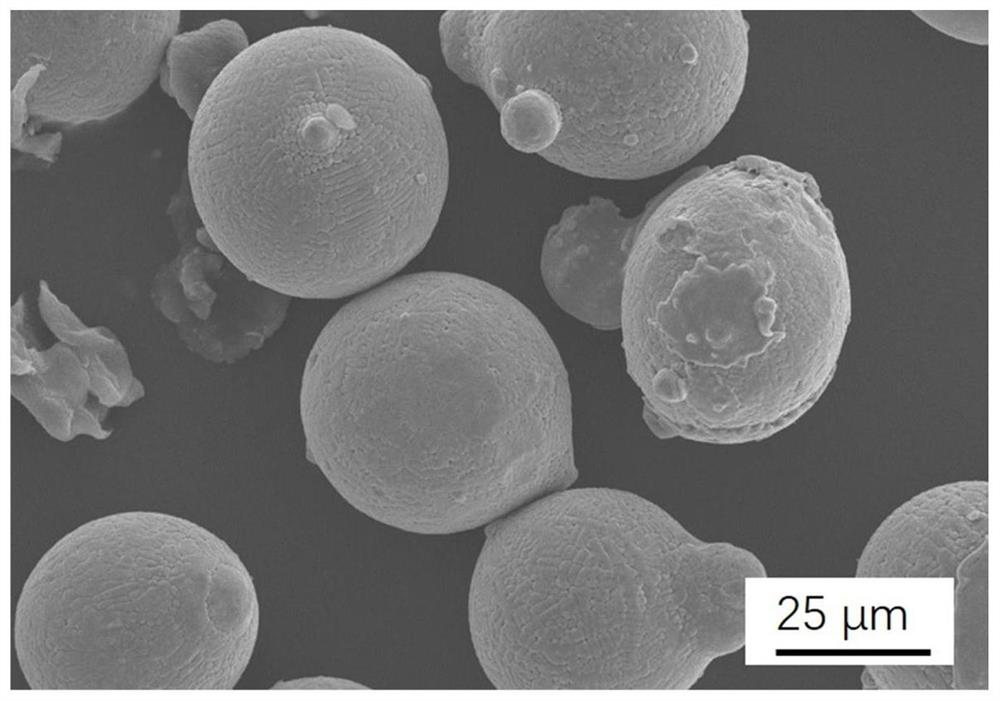

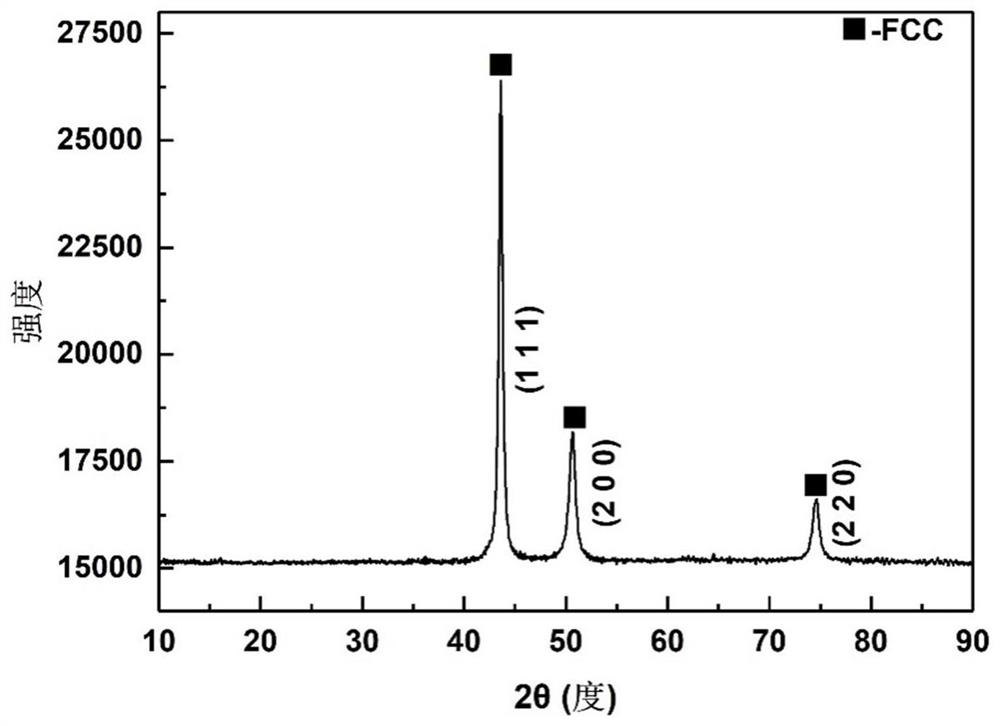

[0032] The chemical composition and mass percentage of the alloy material in this embodiment are: nickel: 18%, cobalt: 18%, chromium: 20%, manganese: 17%, iron: balance, and unavoidable impurities. Spraying process parameters are: current: 600A, argon gas flow rate: 38L / min, hydrogen gas flow rate: 12L / min, powder feeding rate: 60g / min, spraying distance: 120mm. figure 1 is the X-ray diffraction (XRD) spectrum of the alloy powder, figure 2 SEM image of alloy powder. image 3 It is the corresponding X-ray diffraction (XRD) spectrogram of the coating prepared in Example 2. Figure 4It is the SEM topography image corresponding to the coating prepared in Example 2. Figure 5 It is the corresponding TEM topography image of the coating prepared in Example 2.

Embodiment 3

[0034] The chemical composition and mass percentage of the alloy material in this embodiment are: nickel: 18%, cobalt: 18%, chromium: 18%, manganese: 17%, iron: balance, and unavoidable impurities. Spraying process parameters are: current: 550A, argon gas flow rate: 30L / min, hydrogen gas flow rate: 10L / min, powder feeding rate: 60g / min, spraying distance: 120mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com