A nanoscale powder mg 2 The preparation method of ni compound

A nano-scale powder and compound technology, which is applied in the field of preparation of nano-powder Mg2Ni compounds, can solve the problems of high preparation cost, complex preparation process, and long cycle, and achieve low cost, simple and reliable process, and improved hydrogen storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

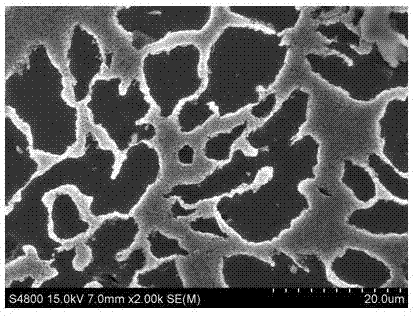

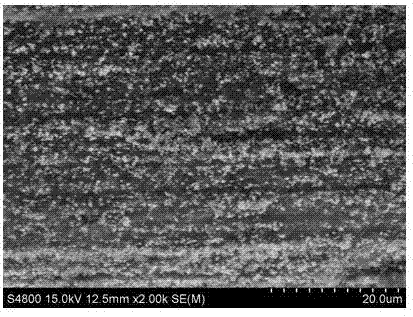

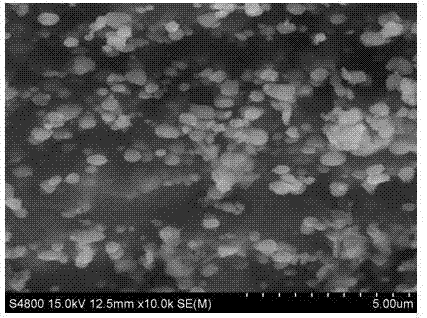

Image

Examples

Embodiment Construction

[0022] One, the preparation steps are as follows:

[0023] 1. After the magnesium is melted, nickel is gradually added, and it is cast into an alloy ingot after stirring and refining.

[0024] The mass percentage of the chemical composition of the magnesium-nickel alloy targeted by this technology is: nickel 5.0-40.0%, and the rest is magnesium and unavoidable impurities.

[0025] The following table is the raw material ratio table of each example (unit: kg)

[0026]

[0027] 2. Each alloy ingot is homogenized below 500°C to eliminate component segregation.

[0028] 3. Each alloy ingot is subjected to equal-channel angular pressing (ECAP), which can be processed repeatedly for multiple passes. The deformation temperature of each pass is between 200°C and 250°C. The refinement effect of the processed microstructure at high temperature is better.

[0029] 4. The magnesium-nickel alloy processed by equal-channel angular extrusion is drawn into magnesium-nickel alloy wire or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com