A kind of high-entropy alloy reinforced and toughened by multi-element doping and its preparation method

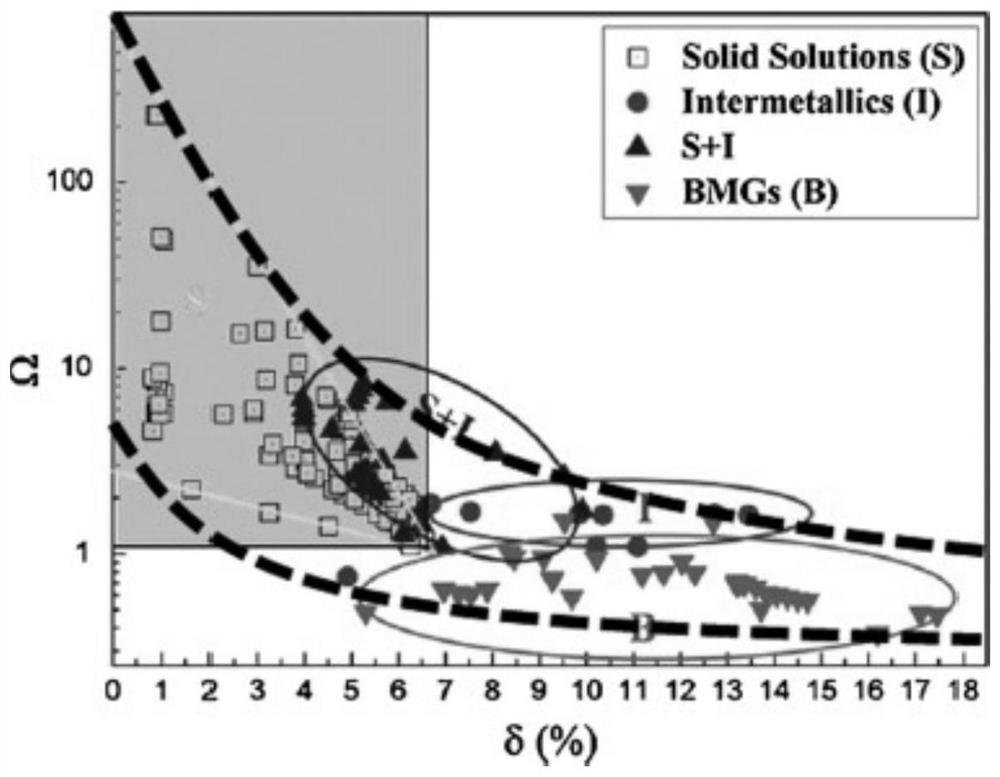

A high-entropy alloy and multi-element technology, which is applied in the field of multi-element doping enhanced and toughened high-entropy alloys and their preparation, to achieve the effects of increasing atomic size difference δ, avoiding difficult processing and analysis, and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

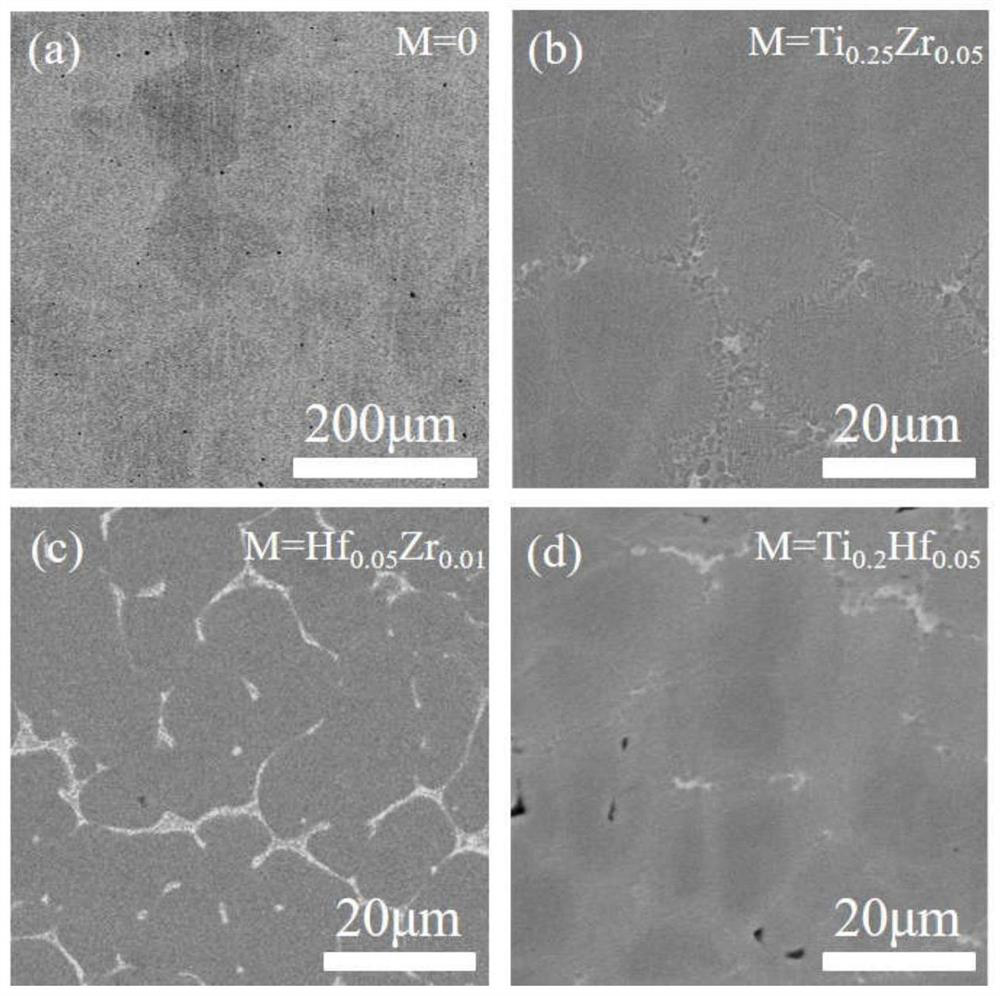

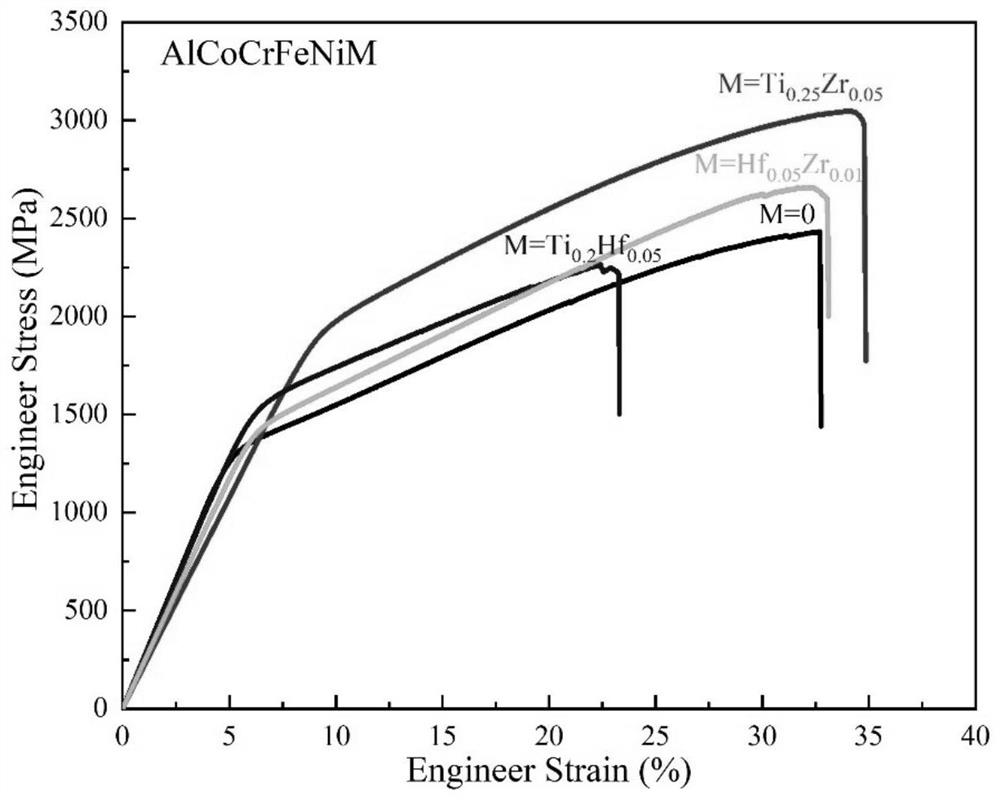

Embodiment 1

[0051] Step 1: Use SiC sandpaper to remove the oxide layer on the surface of Al, Co, Cr, Fe, Ni, Ti and Zr metal raw materials with a purity of not less than 99.99%, then place it in an ultrasonic cleaner and clean it with alcohol, take it out and air dry it naturally;

[0052] Step 2: Calculate according to the atomic ratio Al:Co:Cr:Fe:Ni:Ti:Zr=20:20:20:20:20:5:1 and weigh the pure metal with a total mass of (30±0.1)g raw material;

[0053] Step 3: Put the raw materials into the copper crucible of the vacuum arc melting furnace in order of the metal melting point from low to high, and the vacuum degree is at least 2.5×10 -3 Pass high-purity argon gas under the environment of Pa;

[0054] Step 4: First smelt pure titanium to absorb the residual oxygen in the furnace cavity; then smelt the alloy, keep the arc for 20-30 seconds, and carry out electromagnetic stirring at the same time, turn it over after the alloy cools down, repeat this more than 4 times , to get AlCoCrFeNiTi ...

Embodiment 2

[0057] Step 1: Use SiC sandpaper to remove the oxide layer on the surface of Al, Co, Cr, Fe, Ni, Hf and Zr metal raw materials with a purity of not less than 99.99%, then place it in an ultrasonic cleaner and clean it with alcohol, take it out and air dry it naturally;

[0058] Step 2: Calculate according to the atomic ratio Al:Co:Cr:Fe:Ni:Hf:Zr=100:100:100:100:100:5:1 and weigh the pure metal with a total mass of (30±0.1)g raw material;

[0059] Step 3: Put the raw materials into the copper crucible of the vacuum arc melting furnace in order of the metal melting point from low to high, and the vacuum degree is at least 2.5×10 -3 Pass high-purity argon gas under the environment of Pa;

[0060] Step 4: First smelt pure titanium to absorb the residual oxygen in the furnace cavity; then smelt the alloy, keep the arc for 20-30 seconds, and carry out electromagnetic stirring at the same time, turn it over after the alloy cools down, repeat this more than 4 times , to get AlCoCrFe...

Embodiment 3

[0063] Step 1: Use SiC sandpaper to remove the oxide layer on the surface of Al, Co, Cr, Fe, Ni, Ti and Hf metal raw materials with a purity of not less than 99.99%, then place it in an ultrasonic cleaner and clean it with alcohol, take it out and air dry it naturally;

[0064] Step 2: Calculate according to the atomic ratio Al:Co:Cr:Fe:Ni:Ti:Hf=20:20:20:20:20:4:1 and weigh the pure metal with a total mass of (30±0.1)g raw material;

[0065] Step 3: Put the raw materials into the copper crucible of the vacuum arc melting furnace in order of the metal melting point from low to high, and the vacuum degree is at least 2.5×10 -3 Pass high-purity argon gas under the environment of Pa;

[0066] Step 4: First smelt pure titanium to absorb the residual oxygen in the furnace cavity; then smelt the alloy, keep the arc for 20-30 seconds, and carry out electromagnetic stirring at the same time, turn it over after the alloy cools down, repeat this more than 4 times , to get AlCoCrFeNiTi ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com