Zr-Ti-Cr-V complex phase hydrogen storage alloy and preparing method thereof

A zr-ti-cr-v, hydrogen storage alloy technology, applied in the field of hydrogen storage materials, can solve the problem of rarely being able to have both, achieves a fast hydrogen absorption rate, is conducive to nucleation and hydrogen diffusion, increase The effect of lattice distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The design alloy composition is ZrTi 0.2 Cr 0.2 V 2 , The ratio is an atomic ratio; the purity of the Zr, Ti, Cr and V raw materials used in the experiment are 99.4%, 99.97%, 99.7% and 99.5% respectively.

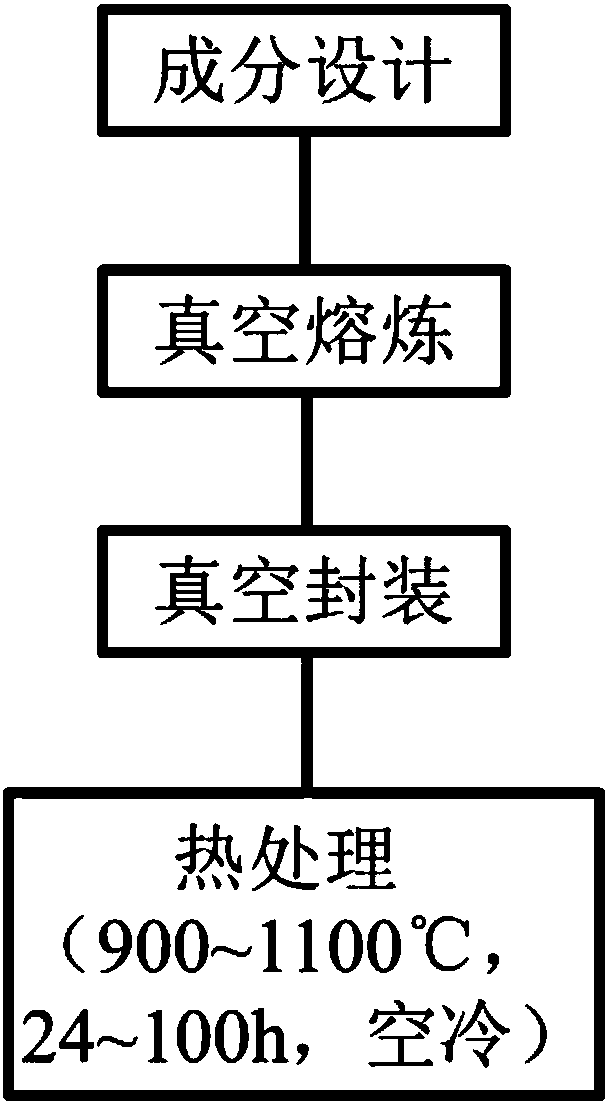

[0028] The preparation process of this embodiment is:

[0029] Step 1, vacuum melting. Put Zr, Ti, Cr and V raw materials into a vacuum arc melting furnace at an atomic ratio of 1:0.2:0.2:2 for melting, fill the melting furnace with argon as a protective atmosphere, and apply magnetic stirring during the melting process to make the ingredients uniform; The solidified ingot is turned up and down, and the alloy ingot is obtained after repeated melting 3 times;

[0030] Step 2, vacuum packaging. Put the obtained alloy ingot into a quartz tube, use argon to purge the inside of the quartz tube, and at the same time evacuate the quartz tube until the vacuum degree reaches 1×10 -3 Complete the sealing of the quartz tube at Pa;

[0031] Step 3, heat treatment. Put th...

Embodiment 2

[0034] The design alloy composition is ZrTi 0.4 Cr 0.1 V 1.8 , The ratio is an atomic ratio; the purity of the Zr, Ti, Cr and V raw materials used in the experiment are 99.4%, 99.97%, 99.7% and 99.5% respectively.

[0035] The preparation process of this embodiment is:

[0036] Step 1, vacuum melting. Put Zr, Ti, Cr and V raw materials into a vacuum arc melting furnace at an atomic ratio of 1:0.4:0.1:1.8 for melting, fill the melting furnace with argon as a protective atmosphere, and apply magnetic stirring during the melting process to make the ingredients uniform; The solidified ingot is turned up and down, and the alloy ingot is obtained after repeated melting 5 times;

[0037] Step 2, vacuum packaging. Put the obtained alloy ingot into a quartz tube, use argon to purge the inside of the quartz tube, and at the same time evacuate the quartz tube until the vacuum degree reaches 1×10 -3 Complete the sealing of the quartz tube at Pa;

[0038] Step 3, heat treatment. Pu...

Embodiment 3

[0041] The design alloy composition is ZrTi 0.6 Cr 0.2 V 1.9 , The ratio is an atomic ratio; the purity of the Zr, Ti and V raw materials used in the experiment are 99.4%, 99.97% and 99.5% respectively.

[0042] The preparation process of this embodiment is:

[0043] Step 1, vacuum melting. Put Zr, Ti, Cr and V raw materials into a vacuum arc melting furnace at an atomic ratio of 1:0.6:0.2:1.9 for melting, fill the melting furnace with argon as a protective atmosphere, and apply magnetic stirring during the melting process to make the ingredients uniform; The solidified ingot is turned up and down, and the alloy ingot is obtained after repeated melting 5 times;

[0044] Step 2, vacuum packaging. Put the obtained alloy ingot into a quartz tube, use argon to purge the inside of the quartz tube, and at the same time evacuate the quartz tube until the vacuum degree reaches 1×10 -3 Complete the sealing of the quartz tube at Pa;

[0045] Step 3, heat treatment. Put the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com