High-strength creep-resistant high-temperature alloy and preparation method thereof

A high-temperature alloy and anti-creep technology, which is applied in the field of metallurgy, can solve problems such as difficult to meet the technical requirements of aviation turboshaft engines, and achieve the effect of improving solid solution strengthening effect, temperature bearing capacity and strength level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

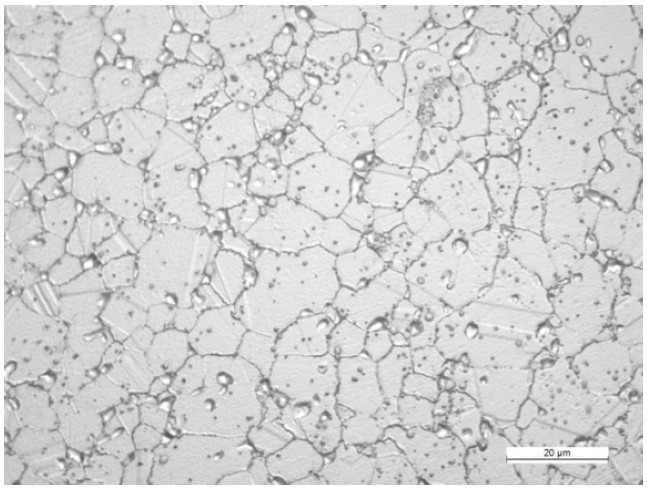

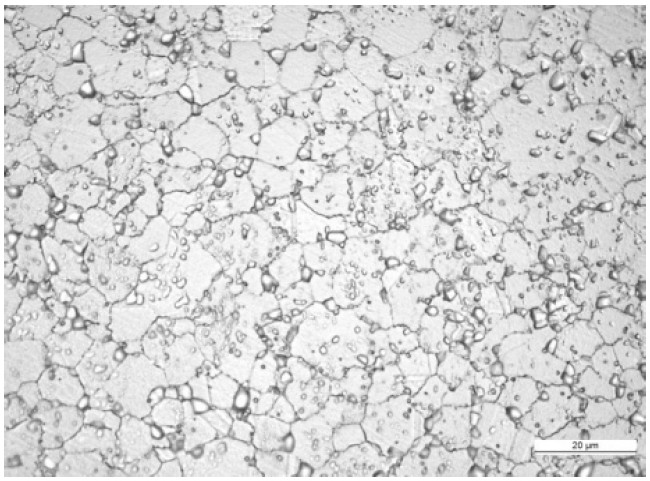

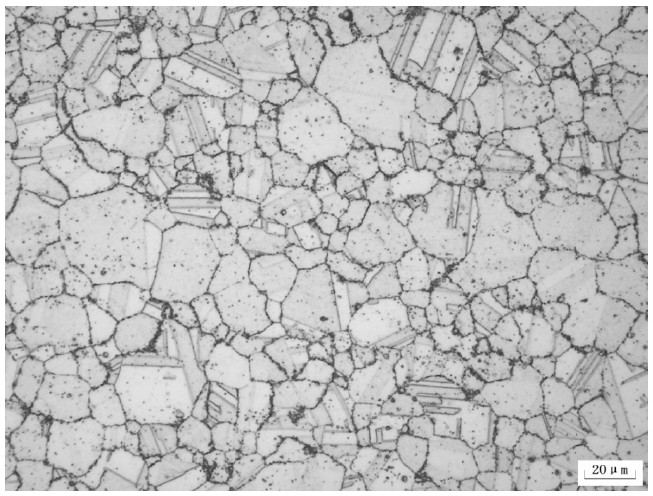

Image

Examples

Embodiment Construction

[0040] In view of this, the present invention provides a high-strength creep-resistant superalloy and a preparation method thereof. The high-strength creep-resistant superalloy prepared by the preparation method can meet the requirements of future aviation turboshaft engines for high temperature resistance, high strength and creep resistance. The demand for variable performance is thus more suitable for practical use.

[0041] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, in conjunction with the accompanying drawings and preferred embodiments, a high-strength creep-resistant superalloy and a preparation method thereof proposed according to the present invention are described below. Embodiments, structures, features and their effects are described in detail as follows. In the following description, different "an embodiment" or "embodiments" do not necessarily refer to the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com