Ferrite-based high-temperature infrared radiation material and preparation method thereof

A high-temperature infrared and ferrite technology, applied in the field of infrared radiation materials, can solve the problems of low emissivity and absorption rate, inability to form doping effect, inactive electromagnetic wave response, etc., achieving low production cost, simple process, excellent Effects of Infrared Radiation Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A ferrite-based high-temperature infrared radiation material and a preparation method thereof. Its preparation steps are as follows:

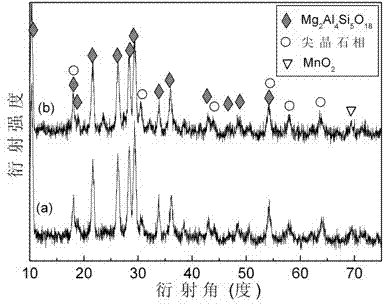

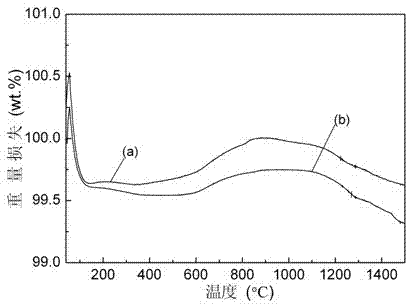

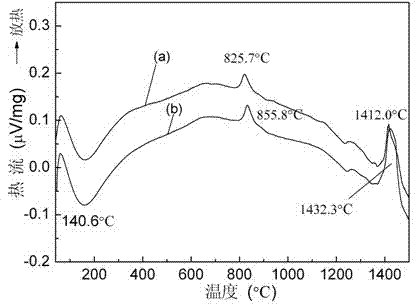

[0027] The first step, preparation of spinel structure ferrite blackening agent

[0028] Press Fe 2 o 3 :MnO 2 :CuO:Co 2 o 3 The mass ratio is x: (8-x): 1: 1 (1≤x≤2) Fe 2 o 3 Fine powder, MnO 2 fine powder, CuO fine powder and Co 2 o 3 Mix the fine powder evenly to get the mixture, then put the mixture into the sagger, then put the sagger with the mixture into the microwave oven, heat it with radiation, raise the temperature to 900~950℃, keep it warm for 30~40min, Cool, and finally pulverize to below 200 mesh to obtain fine powder of spinel structure ferrite blackening agent, and set aside.

[0029] The second step, preparation of ferrite-based high-temperature infrared radiation materials

[0030] The fine powder of cordierite and the fine powder of ferrite blackening agent with spinel structure prepared in the first step ar...

Embodiment 2

[0032] A ferrite-based high-temperature infrared radiation material and a preparation method thereof. Its preparation steps are as follows:

[0033] The first step, preparation of spinel structure ferrite blackening agent

[0034] Press Fe 2 o 3 :MnO 2 :CuO:Co 2 o 3 The mass ratio is x: (8-x): 1: 1 (2≤x≤3) Fe 2 o 3 Fine powder, MnO 2 fine powder, CuO fine powder and Co 2 o 3 Mix the fine powder evenly to get the mixture, then put the mixture into the sagger, then put the sagger with the mixture into the microwave oven, heat it with radiation, raise the temperature to 950~1000℃, keep it warm for 40~50min, Cool, and finally pulverize to below 200 mesh to obtain fine powder of spinel structure ferrite blackening agent, and set aside.

[0035] The second step, preparation of ferrite-based high-temperature infrared radiation materials

[0036] The mullite fine powder and the spinel structure ferrite blackening agent fine powder prepared in the first step are mixed accor...

Embodiment 3

[0038]A ferrite-based high-temperature infrared radiation material and a preparation method thereof. Its preparation steps are as follows:

[0039] The first step, preparation of spinel structure ferrite blackening agent

[0040] Press Fe 2 o 3 :MnO 2 :CuO:Co 2 o 3 The mass ratio is x: (8-x): 1: 1 (3≤x≤4) Fe 2 o 3 Fine powder, MnO 2 fine powder, CuO fine powder and Co 2 o 3 Mix the fine powder evenly to get the mixture, then put the mixture into the sagger, then put the sagger with the mixture into the microwave oven, heat it with radiation, raise the temperature to 1000~1050℃, keep it warm for 50~60min, Cool, and finally pulverize to below 200 mesh to obtain fine powder of spinel structure ferrite blackening agent, and set aside.

[0041] The second step, preparation of ferrite-based high-temperature infrared radiation materials

[0042] The spodumene fine powder and the spinel structure ferrite blackening agent fine powder prepared in the first step are mixed acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com