Composite pretreatment process for improving ion nitriding efficiency

A technology of ion nitriding and pretreatment, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of slow infiltration rate and shallow infiltration layer, etc., to increase the thickness of the infiltration layer and improve the nitriding The effect of speed and compound layer thickness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Process the raw steel into a sample with a size of 10mm×10mm×5mm;

[0028] (2) Refining and tempering the sample, first raising the temperature to 860°C for 12 minutes, then oil cooling, then raising the temperature to 600°C for 30 minutes, then air cooling to room temperature;

[0029] (3) Grind the sample with 500#~2000# SiC sandpaper to the mirror surface, wash with deionized water and soak in 20ml of acetone, perform ultrasonic cleaning for 15min to remove oil, and dry it for use;

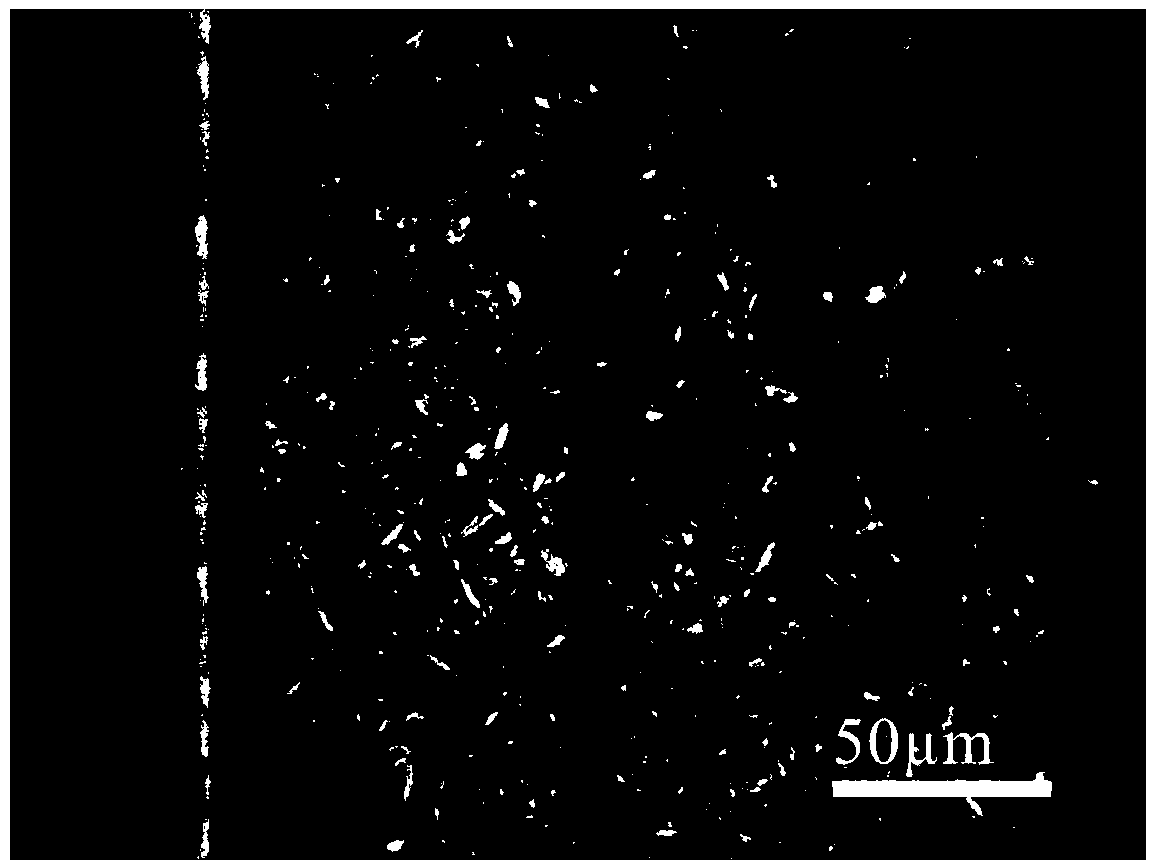

[0030] (4) Clamp the sample on the laser shock strengthening test platform, set the laser wavelength to 1064nm, the pulse width to 10ns, the laser energy to 3J, the shape of the spot to be circular, the diameter of the spot to be 3mm, and the overlapping rate of the spot to be 50%; the laser passes through the transparent flowing water The layer acts on the black tape coating coated on the surface of the sample. The black tape coating absorbs the laser energy and induces high-intensi...

Embodiment 2

[0034] (1) Process the raw steel into a sample with a size of 10mm×10mm×5mm;

[0035] (2) Refining and tempering the sample, first raising the temperature to 860°C for 12 minutes, then oil cooling, then raising the temperature to 600°C for 30 minutes, then air cooling to room temperature;

[0036] (3) Grind the sample with 500#~2000# SiC sandpaper to the mirror surface, wash with deionized water and soak in 20ml of acetone, perform ultrasonic cleaning for 15min to remove oil, and dry it for use;

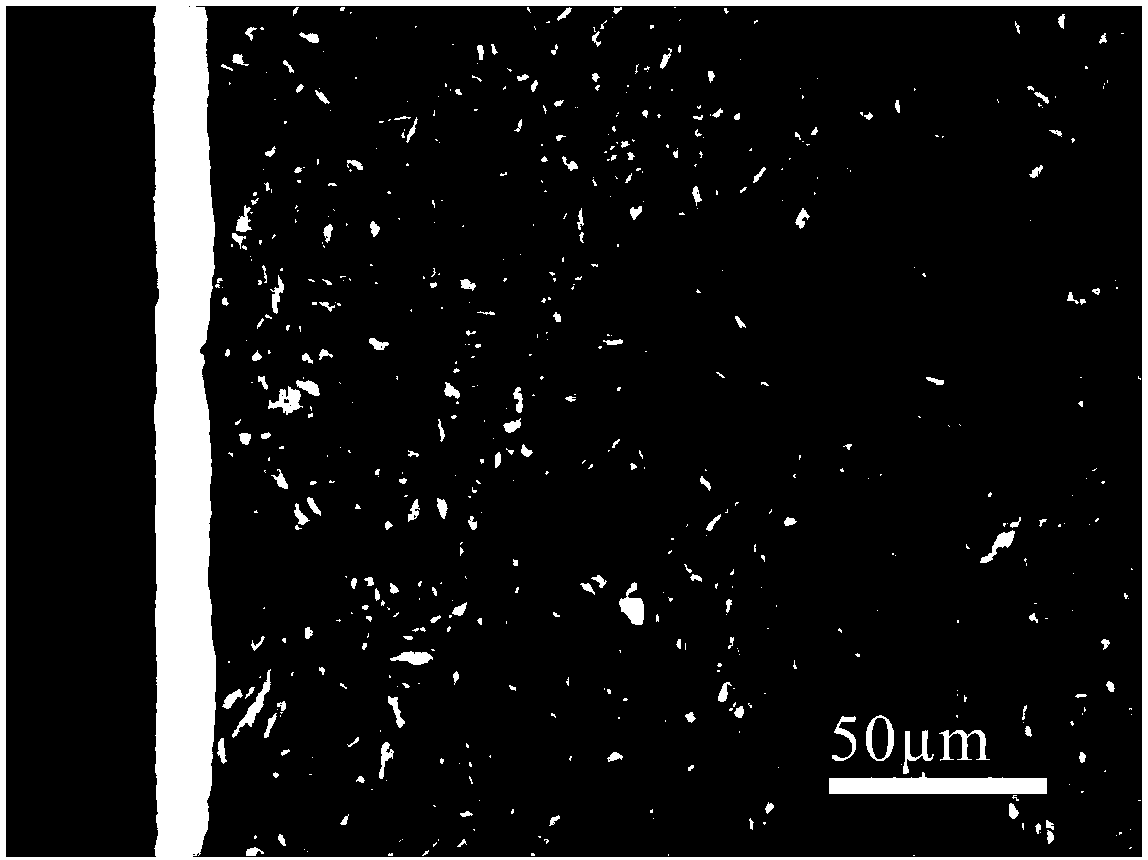

[0037] (4) Clamp the sample on the laser shock strengthening test platform, set the laser wavelength to 1064nm, the pulse width to 30ns, the laser energy to 10J, the shape of the spot to be circular, the diameter of the spot to be 3mm, and the overlapping rate of the spot to be 50%; the laser passes through the transparent flowing water The layer acts on the black tape coating coated on the surface of the sample. The black tape coating absorbs the laser energy and induces high-intens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com